– –

– –

16

17

7. The Set Module button adds the address and Permissions Mask to

the list. If a current module is selected, then the Permissions can be

updated. The Remove module button removes the selected module

from the list. The Remove All Modules button removes all of the

modules from the list.

8. The Interrupt Mask sets the conditions under which an interrupt is to

be generated on the CMD_DATA_OUT line. The Message Select menu

sets the type of message that triggers the interrupt when the Selected

Message Ready box is checked.

9. The TX Power Level Source configures how the transmitter output

power is set. It uses either the voltage on the LVL_ADJ line or the value

in the box. The accepted range of values is –20 to +12.

10. The Transmitter Mode selection sets whether the module transmits

command messages when a status line input is asserted or when it

receives a software command.

11. The Receiver Mode selection turns the receiver on or off for power

savings. If the module is set as an Initiating Unit only with all status lines

as inputs, then the receiver is disabled by default.

12. The Status Line Direction selection sets how the status lines are

configured as inputs and outputs. Either the C0 and C1 hardware lines

are used to set them in groups of 4 or the Status Line Mask is used to

set them individually.

13. The Latch Status Outputs selection configures how the latched or

momentary operation for each status line output is set. Either the

LATCH_EN hardware line is used to set all of the lines the same way or

the Latch Mask is used to set the lines individually.

14. The Custom Data box enables a custom 2-byte value to be loaded

into the module to be transmitted with each control message or

Acknowledge with Data packet.

15. The Duty Cycle configuration sets the interval and Keep on times for

automatically cycling power to the receiver.

16. The Module Identity box displays the module type, firmware version

and serial number of the active module.

17. The Read All button reads all of the current configurations from the

active module.

18. The Submit button writes all changes to the active module.

19. The Set Defaults button restores the active module to factory default

conditions.

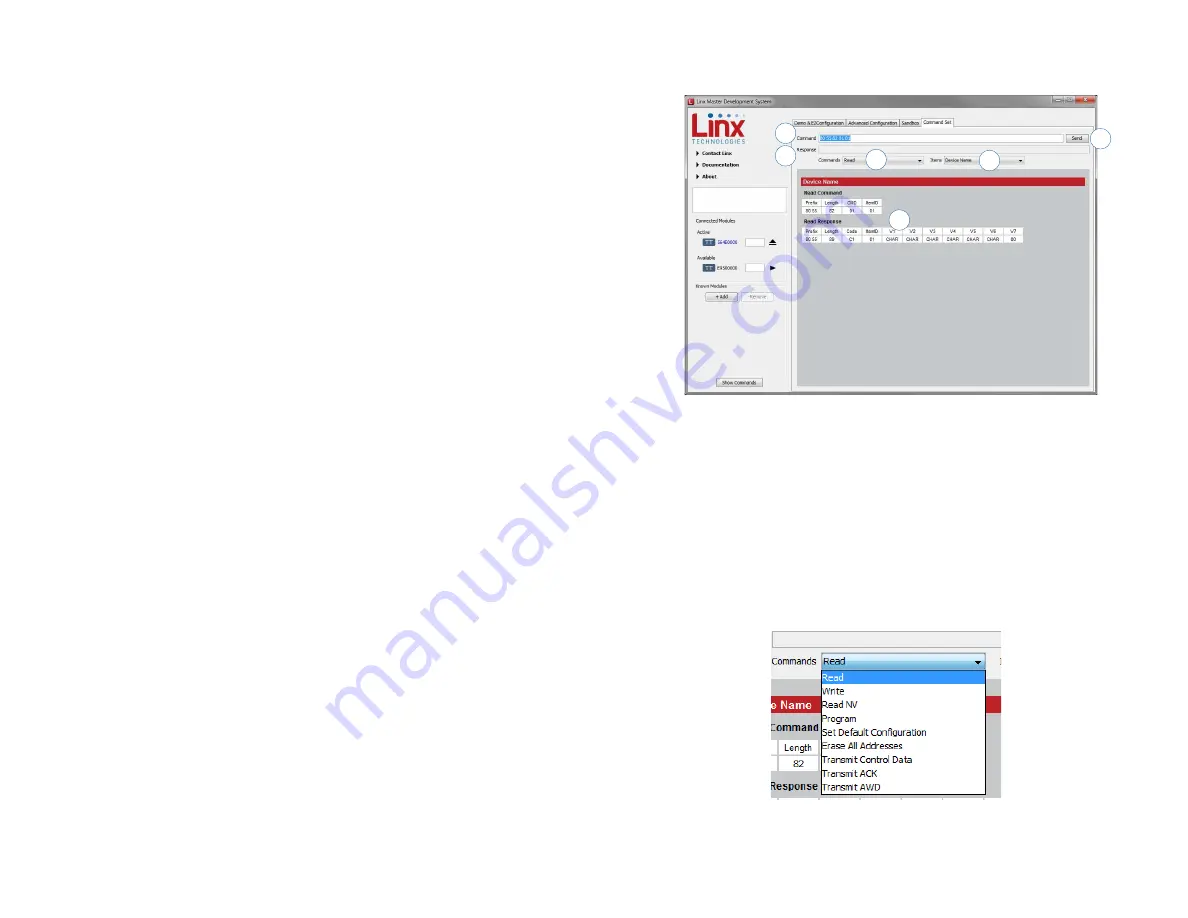

The Command Set tab (Figure 17) allows specific commands to be written

to the module.

1. The Command box shows the hexadecimal values that are written to

the module. Values can be typed into the box or a command can be

selected from the Commands menu.

2. The Response box shows the hexadecimal values that are returned

from the module in response to a command.

3. The Commands drop-down menu shows all of the commands that

are available for the active module (Figure 18). Selecting one of the

commands from this menu automatically fills in the Command box. The

values can be adjusted by typing in the box.

4

1

2

3

6

5

Figure 17: The Master Development System Software Command Set Tab

Figure 18: The Master Development System Software

Demo Command Set Tab Commands Menu