Concave Fillet Weld

A fillet in which the contour of the weld is below a straight line joining

the toes of the weld. It should be noted that a concave fillet weld of

a specified leg length has a throat thickness less than the effective

throat thickness for that size fillet. This means that when a concave

fillet weld is used, the throat thickness must not be less than the

effective measurement. This entails an increase in leg length beyond the

specified measurement.

The size of a fillet weld is affected by the electrode size, welding speed

or run length, welding current and electrode angle. Welding speed and

run length have an important effect on the size and shape of the fillet,

and on the tendency to undercut.

Insufficient speed causes the molten metal to pile up behind the arc

and eventually to collapse. Conversely, excessive speed will produce

a narrow irregular run having poor penetration, and where larger

electrodes and high currents are used, undercut is likely to occur.

Fillet Weld Data

Nominal Fillet

Size (mm)

Minimum Throat

Thickness (mm)

Plate Thickness

(mm)

Electrode Size

(mm)

5.0

3.5

5.0–6.3

3.2

6.3

4.5

6.3–12

4.0

8.0

5.5

8.0–12 & over

4.0

10.0

7.0

10 & over

4.0

Selection of welding current is important. If it is too high the weld

surface will be flattened, and undercut accompanied by excessive spatter

is likely to occur. Alternatively, a current which is too low will produce a

rounded narrow bead with poor penetration at the root. The first run in

the corner of a joint requires a suitably high current to achieve maximum

penetration at the root. A short arc length is recommended for fillet

welding. The maximum size fillet which should be attempted with one

pass of a large electrode is 8.0 mm. Efforts to obtain larger leg lengths

usually result in collapse of the metal at the vertical plate and serious

undercutting. For large leg lengths multiple run fillets are necessary.

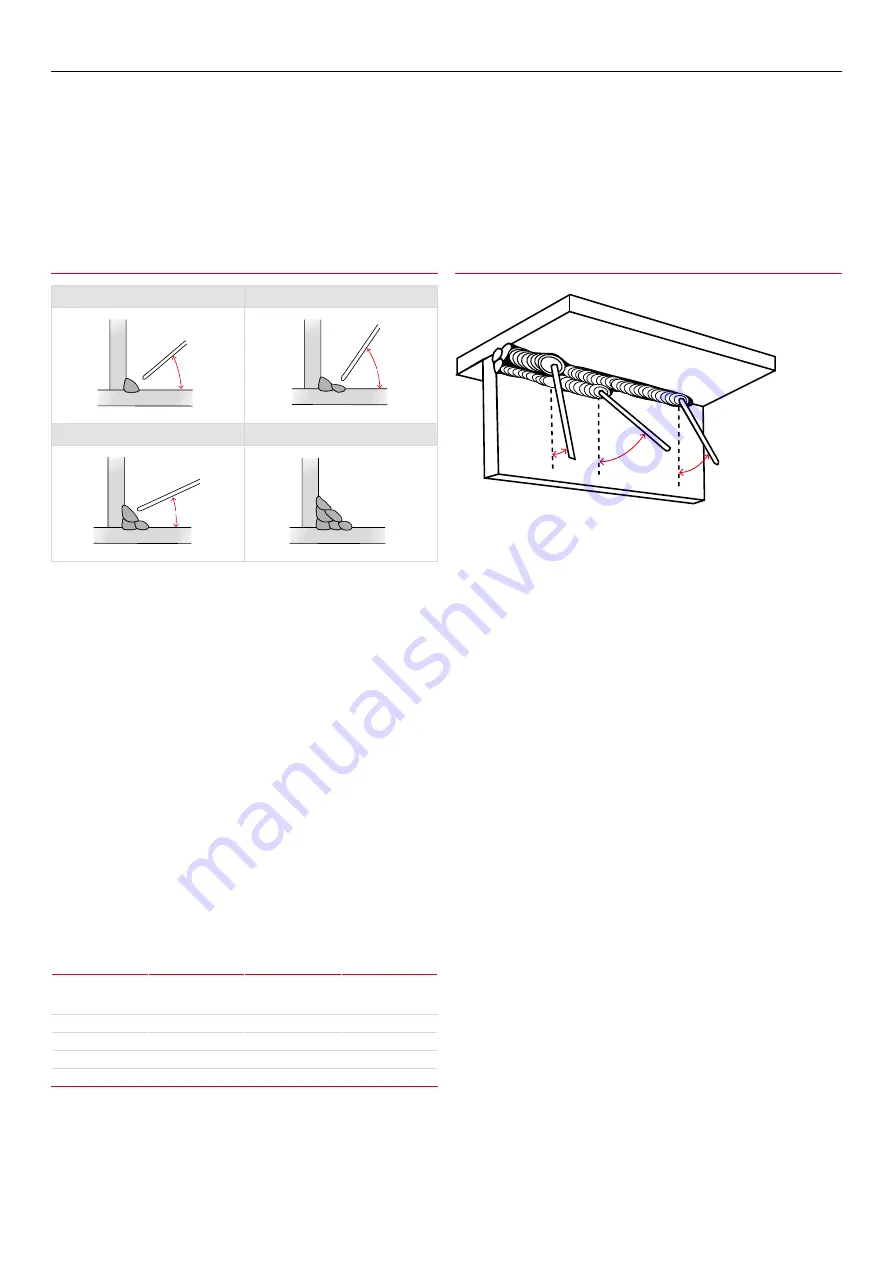

These are built up as shown. The angle of the electrode for various runs

in a downhand fillet weld is shown on the next page.

Recommended Electrode Angles for Fillet Welds

Multi-run horizontal fillets have each run made using the same run

lengths (run length per electrode table). Each run is made in the same

direction, and care should be taken with the shape of each, so that it has

equal leg lengths and the contour of the completed fillet weld

is slightly convex with no hollows in the face.

Vertical fillet welds can be carried out using the upwards or downwards

technique. The characteristics of each are: upwards – current used is low,

penetration is good, surface is slightly convex and irregular. For multiple

run fillets large single pass weaving runs can be used. Downwards –

current used is medium, penetration is poor, each run is small, concave

and smooth (only BOC Smootharc 13 is suitable for this position).

The downwards method should be used for making welds on thin

material only. Electrodes larger than 4.0 mm are not recommended

for vertical down welding. All strength joints in vertical plates 10.0

mm thick or more should be welded using the upward technique. This

method is used because of its good penetration and weld metal quality.

The first run of a vertical up fillet weld should be a straight sealing run

made with 3.15 mm or 4.0 mm diameter electrode. Subsequent runs

for large fillets may be either numerous straight runs or several wide

weaving runs.

Recommended Angles for Overhead Fillet Welds

Recommended Electrode Angles for Fillet Welds

1st Run

2nd Run

Elect

rode

40°

55–60°

20–30°

1

2

3

4

5

6

Elect

rode

40°

55–60°

20–30°

1

2

3

4

5

6

3rd Run

Multi-run Fillet

Elect

rode

40°

55–60°

20–30°

1

2

3

4

5

6

Elect

rode

40°

55–60°

20–30°

1

2

3

4

5

6

30˚

45˚

15˚

20

BOC Smootharc Advance II MIG 400R Operating manual