Subject to modifications

Page 5 of 16

User Manual

Operation Instructions

4.1EN-10004-A08

LINCOLN G

MB

H • P

OSTFACH

1263 • D-69183 W

ALLDORF

• T

EL

+49 (6227) 33-0 • F

AX

+49 (6227) 33-259

Safety Instructions

Appropriate Use

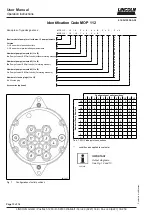

The MOP 112 mechanically-operated oil lubrication pump is a

single-line system designed for the lubrication of link chains in

agricultural equipment and other applications.

The oil system is able to supply mineral, synthetic or biologi-

cal oils (see chapter "Technical Data").

Misuse

Any use of the MOP 112 that is not expressly mentioned in

this User Manual will be regarded as misuse.

If the MOP 112 is used or operated in a different manner

other than specified, any claim for warranty or liability will be

null and void.

6001a02

NOTE

If personal injury or material damage

occurs as a result of inappropriate opera-

tion, e.g.

- safety instructions are ignored

- use of inadequate lubrication oil

- incorrect installation of the MOP

no claims or legal actions may be taken

against Lincoln GmbH.

Exclusion of Liability

The manufacturer of the MOP 112 does not accept any liabil-

ity for damages caused by

poor lubrication due to

- late refilling of reservoir

- wrong position of the MOP 112 (inclined position of

MOP or reservoir)

- wrong installation of mechanical drive

- failure of mechanical drive (caused by system operator)

operation with contaminated oils

use of oils that are inappropriate or only conditionally

appropriate for the lubricating device or which are not

pumpable

inappropriate disposal of used or contaminated oils or

components

arbitrary modification of system parts

use of unauthorized spare parts

Accident Prevention Regulations

To prevent accidents, observe all city, state or provincial and

federal safety regulations of the country in which the

MOP 112 will be used.

General Safety Instructions

MOP 112 mechanically-driven oil lubrication pumps

- are designed with state-of-the-art technology

- can be assembled for safe operation

Incorrect use may result in bearing damage caused by

insufficient or excessive lubrication of the link chains

Modifications or alterations to an installed system by the

customer are subject to prior consultation with the manu-

facturer of the lubrication system or with its appointed

dealer.

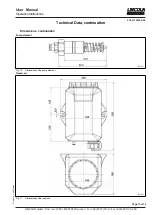

MOP 112 oil pumps are to be installed with the filler cap

showing to the top

After each transport make sure that the pump supplies oil.

Operation, Maintenance and Repair

1013A94

CAUTION!

Before starting any maintenance or repair

work, disconnect the MOP 112 from the

power supply to avoid unintended opera-

tion.

1013A94

ATTENTION!

Malfunctions or damages due to contami-

nation!

Avoid any contamination when

-

opening the lubricating device

-

carrying out maintenance or repair

work

-

refilling oil

Repairs

Repairs may be performed only by authorized and qualified

persons who are familiar with all applicable regulations.

Operation/ Maintenance

MOP 112 mechanically-driven oil lubrication pumps

shall regularly be filled with clean oil through the filter

insert 9 (Fig. 5)

shall be checked at regular intervals (approx. every 2

days) on whether the pump actually supplies oil (visual

control).

Disposal

Dispose of used or contaminated oils according to the legal

regulations pertaining to environmental protection.