F-1

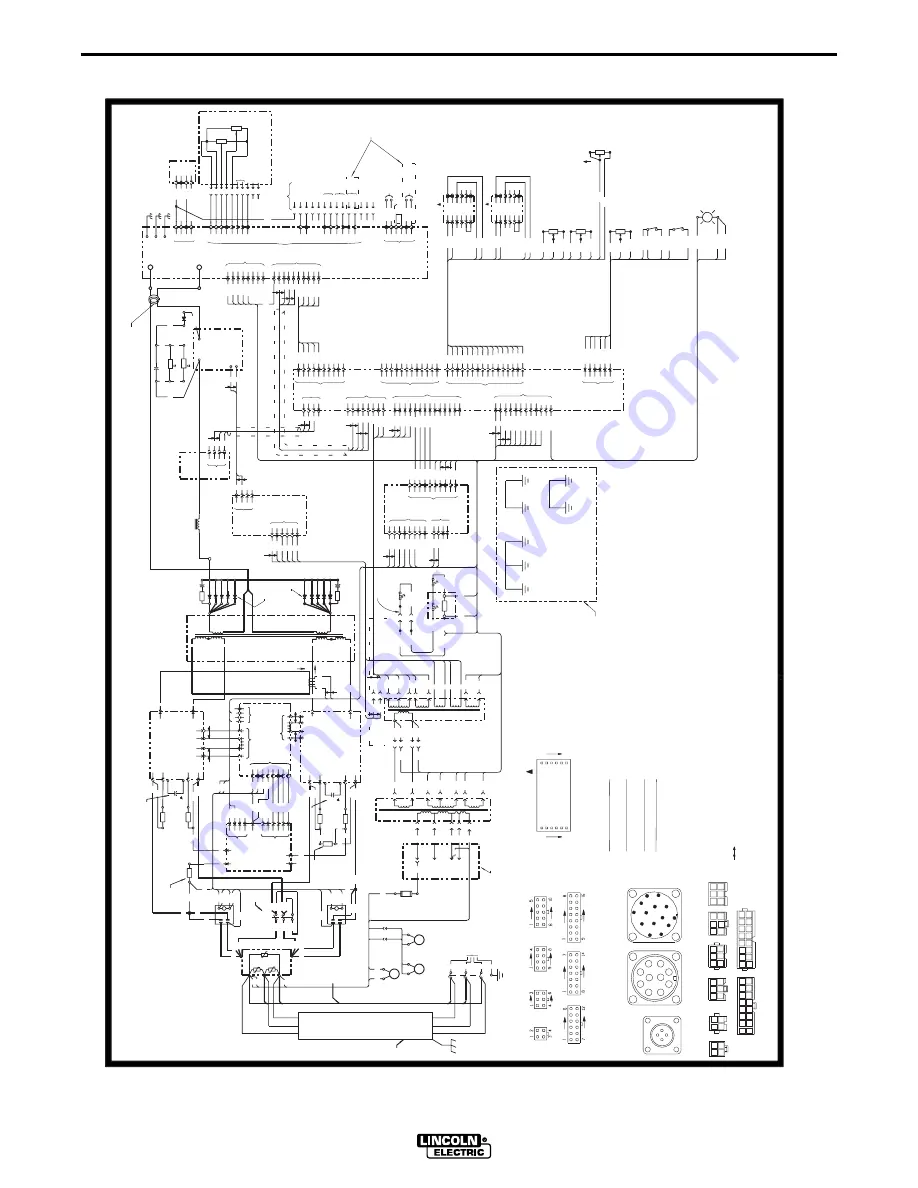

DIAGRAMS

F-1

INVERTEC STT II

R

32A

32B

15

16

J22

R

B

18V

32C

43A

R

U

3

18V

501

B

504

W

4

5

5

275

1

8

6

3

311

10

J6

1

212A

9

7

212

352

212B

503A

Y

301

305

245

223

8

11

3

1

3

503

24V

351

244

CASE

CASE

BACK

PLATFORM

4 AMP

S

BOTTOM

S

OUTSIDE

I

YY

4,5

12D

N

O

O

12

H3

H1

FAN

SLOW

12B

RIGHT

MOTOR

BLOW

H1

1

J11

6

5

379

2

J9

CR2

H3

3

4

2W

10K

CW (MAX)

353

362

363

CONTROL

BACKGROUND

2

12

6

7

4

10

3

N.L.

ASSEMBLY

INPUT

LINE

POWER

LINE

LOAD

D

C

B

A

F

S1

POWER

OFF

W

ON

U

A

INPUT

PER

R

N.A.

V

B

B

W

C

G

C

B

C

A

B

FILTER

A

52

TRIGGER

CORE

3

1

7

5

6

8

2

4

8

7

14

12C

12D

- ARC

+ ARC

CURRENT

METER

VAC

12D

A

378

11

363

J4

CW (MAX)

11

22

33

44

5

6

5

359

358

2W

10K

R11

3

5

377

5

6

6

TRANSFORMER

D1

O

374

N

I

O

T3

CURRENT

N

2

5

N.E.

4

371

1

3

4

3

10

J5

R

210

211A

502

246

212C

J3

6

B

Y

9

364

365

366

2

5

1

367

369

368

W

B

2

4

12

9

1

5

7

8

9

13

10

1

J28

10

11

8

9

7

5

8

10

5

3

1

4

2

4

6

6

J33

2

372

372

4

371

5

J1

6

7

J27

2

376

R

1

1

4

370

370

376

374

371

B

3

8

12

115V

374

10

1

32

2

33B

8

7

33A

J26

B

3

E

R

B

W

4

290A

1

10

367A

369

.045

502

(-)

INDICATOR

J25

115

223

357

356

5

355

6

354

6

2

1

CB2

J37

403

504

TRANSFORMER

AUXILIARY

T1

AUXILIARY

T4

N.D.

TRANSFORMER

13

1

501

220-

212A

150 5W

4

0V

H3

H2

H1

H1

9A

9A

9D

9A

PROTECTION

13

9C

R

W

S7

RECONNECT

1

12B

12B

212C

287

43A

R

18V

4

13

359

7

14

2

356

358

355

354

357

352

16

10

351

360

15

353

361

2

1

362

244

303

303

242

302

371A

302

374A

304

304

275

305

243

2

301

4

240

241

DARLINGTON

12

52

2

12D

2

4

W

1

D3

4

S

F

5

D4

1

BOARD

3

J16

TOP

D5

5

7

DRIVER

F

12B

MOTOR

FAN

LEFT

H1

MOTOR

TOP

H3

FAN

H1

H3

H1

D13

RECTIFIER

TP2

TP1

-

TP3

9D

J16, J28

J34

A

N.K.

413

416

405

408

406

VAC

1

VAC

7

3

4

3

2

1

F

8

52

314

315

J13

ELECTRODE SENSE LEAD

360

367

S2

VAC

368

367A

STAINLESS

R12

42

S3

.035

INTERFACE

503

TRIGGER

MILD

378

PEAK

377

PEAK

METER

BACKGROUND

CONTROL

HOT START

CW

WIRE TYPE

2W

500K

TAILOUT

CONTROL

R14

N.J.

REMOTE

1

5

407

2

6

6

3

115

350

J35

9

12

11

6

J17

J23

J24

METER PINOUT (VIEWED FROM BACK OF METER)

ELECTRICAL SYMBOLS PER E1537

W

18V

N

J2

2

J23

Y

380-

4

415V

H3

1

H2

H3

230V

200-

208V

N.M.

BACK

FOR SINGLE PHASE INPUT: CONNECT GREEN LEAD TO GROUND PER NATIONAL ELECTRIC CODE.

6V

10V

J24

18V

THERMOSTAT

COLOR CODE:

U

FAN

U

Y

WRAP RED LEAD WITH TAPE TO PROVIDE 600V. INSULATION.

J26

CONNECT BLACK & WHITE LEADS TO SUPPLY CIRCUIT.

B = BLACK

CASE

TRAY

G = GREEN

N = BROWN

FRONT

NOTES:

O = ORANGE

R = RED

W = WHITE

N.A.

J25

Y = YELLOW

U = BLUE

1. FOR MACHINES SUPPLIED WITH INPUT CABLE

N.M. PRESENT ON EUROPEAN VERSIONS, CODE 10383 AND HIGHER.

FOR SINGLE PHASE INPUT: GROUND MACHINE PER NATIONAL AND LOCAL ELECTRICAL CODES.

CONNECT TERMINALS U, V & W TO SUPPLY CIRCUIT.

CONNECT TERMINALS U & W TO SUPPLY CIRCUIT.

FOR THREE PHASE INPUT: GROUND MACHINE PER NATIONAL AND LOCAL ELECTRICAL CODES.

N.B. SINCE COMPONENTS OR CIRCUITRY OF A PRINTED CIRCUIT BOARD MAY CHANGE WITHOUT AFFECTING

COMPONENTS OR CIRCUITRY HAVING A COMMON CODE NUMBER.

THE INTERCHANGEABILITY OF A COMPLETE BOARD, THIS DIAGRAM MAY NOT SHOW THE EXACT

CONNECTION SHOWN IS FOR 440-460V OPERATION.

N.D. PLACE "A" LEAD ON APPROPRIATE CONNECTION FOR INPUT VOLTAGE.

N.E. D1 THRU D5 OUTPUT DIODES ARE A MATCHED SET.

D7 THRU D11 OUTPUT DIODES ARE A MATCHED SET.

9

N.F. R1, R9 BLEEDER RESISTORS ARE A MATCHED SET.

J21

1

N.G. C1, C2 CAPACITORS ARE A MATCHED SET.

P21

2

PINOUT OF FRONT PANEL CONNECTORS (REAR VIEW)

3

4

3

5

J29. J31

2

CONNECTION SHOWN IS FOR 380-460V OPERATION.

6

N.H. PLACE SWITCH IN APPROPRIATE POSITION FOR INPUT VOLTAGE.

1

6

N.I. DENOTES A TWISTED WIRE PAIR OR GROUP.

1

5

P29, P31

2

4

3

J30

4

3

5

2

6

1

P30

6

1

1

5

J22

9

FOR THREE PHASE INPUT: CONNECT GREEN LEAD TO GROUND PER NATIONAL ELECTRIC CODE.

2

2

4

3

2

N.K. NOT PRESENT ON EUROPEAN VERSIONS, CODE 10309 AND HIGHER.

4

1

10

5

3

11

4

6

12

N.L. PRESENT ON EUROPEAN VERSIONS, CODE 10309 AND HIGHER.

4

13

8

3

14

P22

15

8

16

7

6

5

16

4

15

3

14

2

13

1

12

11

10

7

J38

J19

N.J. NOT PRESENT ON EUROPEAN VERSION.

2. FOR MACHINES NOT SUPPLIED WITH INPUT CABLE

CONNECT BLACK, RED & WHITE LEADS TO SUPPLY CIRCUIT.

J39

1

2

3

4

310

309

310A

310

309A

309A

310A

2

6

J7

224A

10

2W

309

INSIDE

12B

25W

+

2200 F

C1

-

BOARD

25

450V

R4

(RIGHT)

3

4

1

5

307

2

3

6

308

J10

8

9D

4

52

52

2

B

2

9

J34

J36

C4

2W

R3

10

.001/400

N.E.

5

W

12C

12A

S

F

OUTSIDE

TOP

CHOKE

BOARD

3

12A

J12

J8

14

N.H.

BOARD

224

R

310

J15

316

9B

9B

12B

401, 403

1, 8

8

371

J22

51

12B

12B

TOP

12B

.001/400

CR1

25

2200 F

450V

9A

25W

-

+

53

9A

+

N.G.

9

R6

12A

R7

12A

12

R

W

R

W

401, 403

402, 404

(LEFT)

BOARD

SWITCH

1, 8

25W

25

4, 5

I

21

WIRE

81

82

GND

4

2

42

41

FEEDER

32

31

J39

N

B

H

L

M

42

414

B

H1

+

C

4

3

2

J

A

8

12

TRANSFORMER

C8

288

4

2 300W

289

R16

288A

SENSE

C2

L3

4

MAIN

1

3

289A

20/400

D11

T2

2

J18

4

F

S

4

313

3

3

2

J14

210A

210

THERMOSTAT

CHOKE

FAN

CASE

BOTTOM

1

1

S

INSIDE

F

BOTTOM

D9

BOTTOM

D10

1

14

311

53

3

4

33C

N

J30

33

1

2

6

6

224

H6

H4

A

440-

460V

A

5

9

J31

42V

H5

H4

115V

J21

R15

C

E

2 300W

G

J38

409

A

412

D

404

CURRENT

F

411

291

H

GND

B

MODULE

B

R

DRIVE

BOARD

14

317

9

9B

9B

402, 404

+

N.G.

N.F.

R5

25

25W

25W

7500

R9

9B

SWITCH

SHROUD

J6, J27, J33

J2, J36

J18, J37

J11, J12, J14

J1, J8,

P.C. BOARD CONNECTOR CAVITY NUMBERING SEQUENCE

212B

32C

33C

D12

J3, J9,

DARLINGTON

E

B

B

402

W

401

W

C

J

410

10K

PB

10K

OPTIONAL

D

CB1

C

76

75

6AMP

F

G

43B

42

9A

9D

9C

3

4

5

BOARD

POWER

8

309

7

308

307

W

14

THERMOSTAT

W

HEATSINK

J22

503A

DARLINGTON

503B

242

243

241

240

374A

371A

11

211A

9

350

5

R1

25W

7500

N.F.

D7

D8

R2

1

2

W

D2

C3

3

53

14

J5, J7,

(VIEWED FROM COMPONENT SIDE OF BOARD)

J15, J35

J10, J13,

J4, J17

E

1

I

3

4

77

K

Y

R13

(+)

10K

2

2W

CW (MAX)

3

361

CONTROL

366

503A

WIRE SIZE

THERMAL

OVERLOAD

364

365

7

6

8

5

16

13

15

14

4

12

11

CONTROL

CURRENT

BOARD

415

31A

33D

6AMP

4

6

246

245

212

2

INLINE CONNECTOR CAVITY NUMBERING SEQUENCE

313

G3136

WIRING DIAGRAM - INVERTEC STT II

(VIEWED FROM WIRE SIDE OF CONNECTOR)

1-9-98B

BG

SENSE

(-)

VOLTAGE

CONNECTION

(+)

2

1

J19

290

PROTECTION BOARD

REMOTE

288B

TOROIDAL

289B

374

3

51

H5

6

51

9B

N.L.

H

N

K

I

B

G

J

A

F

L

M

H

C

A

E

G

D

I

4

F

B

J

E

3

C

2

D

1

NOTE: This diagram is for reference only. It may not be accurate for all machines covered by this manual. The specific diag

ram for a particular code is pasted inside

the machine on one of the enclosure panels. If the diagram is illegible, write to the Service Department for a replacement. G

ive the equipment code number..