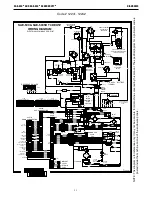

WELDER CONTROLS

POLARITY SWITCH

Turn the Arc Polarity switch to electrode positive or

electrode negative as required for each particular

application.

CONTROL OF WELDING CURRENT

Purpose of Controls

The continuous “Current Control” is the main current

adjuster. The “Job Selector” is both a fine current

adjuster and the continuous Open Circuit Voltage

adjuster. Open Circuit Voltage (OCV) controls the arc

characteristics.

“Job Selector”

The “Job Selector” dial is divided into four colored

sections providing OCV ranges as follows:

Color

Title

OCV Range

White

Large Electrodes

High OCV

Black

Normal Welding

Medium OCV

Red

Overhead & Vertical Low OCV

Grey

Special Applications Extra-Low OCV

The “Job Selector” is usually set in the black range

because it provides a soft “Buttering “ arc desired for

most welding. Some operators prefer to set the “Job

Selector” in the red range for a snappy “Digging” arc

when welding vertical up or overhead.

“Current Control”

Do not adjust the “Current Control” while welding

because this can damage the control.

------------------------------------------------------------------------

The “Current Control” dial is calibrated in amperes on

three separate colored dials corresponding to the

white, black and red ranges of the “Job Selector” dial.

For example: when the “Job Selector” is set on the

black range, the approximate welding current is indi-

cated on the black scale of the “Current Control” dial.

How to Set the Controls

Assume you want a normal soft arc and about 135

amps, using a 5/32” (4.0 mm) electrode:

1. Set the “Job Selector” at the center of the black

range.

2. Set the “Current Control” to read 135 amps on the

black dial.

3. Start to weld.

4. If you want a little more current, turn the “Job

Selector” up (counterclockwise) to increase current.

If you want a little less current, turn the “Job

Selector” down (clockwise) to decrease current.

5. If dialing the desired current with the “Job Selector”

moves the setting outside the black range causing

undesirable arc characteristics, turn the “Job

Selector” back to the center of the black range. Then

turn the “Current Control” up or down a little as

needed. Readjust the “Job Selector” for the exact

characteristics and current desired.

REMOTE CONTROL

A receptacle and “Local/Remote” control switch on the

lower front control panel and a remote control box with

100 ft. (30.5 m) of cord for adjusting the OCV at the

welding site are standard. Putting the switch in the

“REMOTE” position allows fine current control at the

remote control box while placing the switch in the

“LOCAL” position allows fine current control at the “Job

Selector” on the machine.

AUXILIARY POWER CONTROLS

Note: See the “MAINTENANCE SECTION” for detailed

information on testing and resetting the GFCI

receptacle.

115 VAC Receptacle

One 20 amp, 115 VAC duplex receptacle with GFCI pro-

tection provides 115 VAC for auxiliary power. A total of

20 amps can be drawn from this receptacle.

230 VAC Receptacle

One 15 amp, 230 VAC duplex receptacle provides 230

VAC for auxiliary power. A total of 13 amps can be drawn

from this receptacle.

Circuit Breakers

The circuit breakers provide separate overload current

protection for each half of the 115 V duplex receptacle.

The circuit breakers provide overload current protection in

both current carrying wires of the 230 V duplex receptacle.

Ground Stud

Provides a connection point for connecting the machine

to earth ground. For the safest grounding procedure refer

to “Machine Grounding” in the INSTALLATION section of

this manual.

Diagnostic Plug

This is used by Field Service shops to connect and trou-

bleshoot engine error codes and is found on a bracket

mounted to the liftbale on the service side.

Parts Located in Current Box Mounted on Liftbale

Glow Relay / Breaker (70A)

Fuel Relay / Breaker (20A)

Idle Time Delay Relay

ECU (Electronic Control Unit) Breaker (30A)

CAUTION

B-4

OPERATION

SAE-500

TM

AND SAE-500

TM

SEVERE DUTY

TM