B-5

OPERATION

B-5

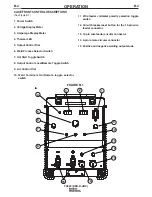

FX450 (RED-D-ARC)

CASE BACK CONTROL

(See Figure B.2)

1. Input Power Cord Access Hole.

1

1

FIGURE B.2

COMMON WELDING PROCEDURES

MAKING A WELD

The serviceability of a product or structure utiliz-

ing the welding programs is and must be the sole

responsibility of the builder/user. Many variables

beyond the control of The Lincoln Electric

Company affect the results obtained in applying

these programs. These variables include, but are

not limited to, welding procedure, plate chemistry

and temperature, weldment design, fabrication

methods and service requirements. The available

range of a welding program may not be suitable

for all applications, and the build/user is and must

be solely responsible for welding program selec-

tion.

The FX450 is a multi-process inverter welder. The

Weld Process Selector Switch

is used to set the

desired weld mode. The FX450 has 4 selectable

welding modes:

1. SMAW –

This is a CC (constant current) weld

mode used for the SMAW stick welding process.

2. GTAW –

This is a CC (constant current) weld

mode used for the GTAW TIG welding process.

3. CV –

This is CV (constant voltage) weld mode used

for welding the GMAW MIG welding process and

the FCAW-GS, flux cored gas shielded welding

process.

4. CV-Innershield –

This is a CV (constant voltage)

weld mode used for welding the FCAW-SS, flux

cored self shielded welding process

The FX450 is also capable of gouging. Gouging can

be done in either the SMAW mode or the CV and CV-

Innershield modes.

In addition to the weld process selector switch, a hot

start toggle, output control dial and arc control dial are

provided to setup and fine tune the welding procedure.

WELD CONTROLS AND DISPLAYS

Weld Process Selector Switch

4 Position switch used to select the welding process.

Hot Start Toggle Switch

The Hot Start control regulates the starting current at

arc initiation. Hot Start can be set to

“Off”

and no

additional current is added at arc start. When set to

the

“On”

position, additional current (relative to the

preset current) is added at arc initiation.

Arc Control Dial

Full range selection of arc control from -10 to +10. In

CV mode, this control is an inductance control. In

stick mode, the control adjusts the arc force.

Output Control Dial

Output control is conducted by a single turn poten-

tiometer. (Adjustment is indicated by the meters.)

When in Remote Mode, this control sets the maximum

welding current of the remote device. For example, full

depression of a foot or hand amptrol results in the pre-

set level of current.

Voltage Display Meter

• Prior to CV operation (current flow), the meter dis-

plays desired preset voltage value.

• Prior to STICK or TIG operation, the meter displays

the Open Circuit Voltage of the Power Source or four

dashes if the output has not been turned on.

• During welding, this meter displays actual average

volts.

• After welding, the meter holds the actual voltage

value for 5 seconds. The displays blink indicating that

the machine is in the "hold" period.

• Output adjustment while in the "hold" period results in

the "prior to operation" characteristics.

WARNING

POWER-UP SEQUENCE

When power is applied to the FX450, the displays will

illuminate and display the voltage and/or amperage

settings.