A-4

INSTALLATION

A-4

INPUT FUSE AND SUPPLY WIRE

CONSIDERATIONS

Refer to Specification in this Installation Section for

recommended fuse, wire sizes and type of the copper

wires. Fuse the input circuit with the recommended

super lag fuse or delay type breakers (also called

"inverse time" or "thermal/magnetic" circuit breakers).

Choose input and grounding wire size according to

local or national electrical codes. Using input wire

sizes, fuses or circuit breakers smaller than recom-

mended may result in "nuisance" shut-offs from

welder inrush currents, even if the machine is not

being used at high currents.

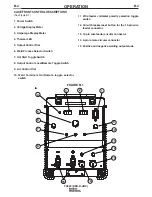

INPUT VOLTAGE SELECTION

Welders are shipped connected for 460 Volt input

voltage. To move this connection to a different input

voltage, see the diagram located on the inside panel

in the reconnect/input connection area, also illustrat-

ed below. If the Auxiliary lead (indicated as ʻAʼ) is

placed in the wrong position and power is applied to

the machine, the machine will protect itself and dis-

play an error message:

• "Err" "058" will be shown on the display.

• The control board and switch boards will blink out

error 58 on their status leds.

• The weld output will be turned off and the control

board will force itself into an idle state.

• The machine will need to have the misconnect

condition removed before it will recover.

ELECTRIC SHOCK

can kill

.

ONLY A QUALIFIED ELECTRICIAN

SHOULD CONNECT THE INPUT

LEADS TO THE FX450. CONNEC-

TIONS SHOULD BE MADE IN ACCORDANCE

WITH ALL LOCAL AND NATIONAL ELECTRI-

CAL CODES AND THE CONNECTION DIAGRAM

LOCATED ON THE INSIDE OF THE RECON-

NECT/INPUT ACCESS DOOR OF THE

MACHINE. FAILURE TO DO SO MAY RESULT

IN BODILY INJURY OR DEATH.

----------------------------------------------------------------------

WARNING

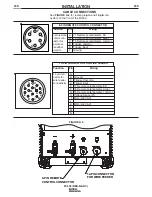

INPUT CONNECTION

(See Figure A.1)

Use a three-phase supply line. A 1.40 inch (36 mm)

diameter access hole for the input supply is located on

the case back. Connect L1, L2, L3 and ground

according to the Input Supply Connection Diagram

decal located on the internal horizontal panel.

To access the reconnect/input supply connection

blocks, remove the 8 screws that secure the case top

of the welder and remove the case top.

FX450 (RED-D-ARC)

RECONNECT TERMINAL BLOCK

• Reconnects auxiliary transformers

for the proper input voltages

POWER SUPPLY TERMINAL BLOCK

• Line Cord/Cable attaches here.

• A ground terminal marked with the symbol shown

is provided separate from this block for connecting the ground

lead of the line cord. (See your local and national electrical

codes for proper grounding methods.)

POWER SUPPLY ACCESS HOLE

• Route input power cable through this hole.

RECONNECT TERMINAL BLOCK

RECONNECT TERMINAL BLOCK

• Reconnects auxiliary transformers

for the proper input voltages

POWER SUPPLY TERMINAL BLOCK

• Line Cord/Cable attaches here.

• A ground terminal marked with the symbol shown

is provided separate from this block for connecting the ground

lead of the line cord. (See your local and national electrical

codes for proper grounding methods.)

POWER SUPPLY ACCESS HOLE

• Route input power cable through this hole.

RECONNECT TERMINAL BLOCK

FIGURE A-1