English 26 English

WARNING

The wire drive door and wire spool case have to be

completely closed during welding.

WARNING

Keep the gun cable as straight as possible when welding

or loading electrode through cable.

WARNING

Do not kink or pull cable around sharp corners.

By applying the principle of occupational health and

safety at welding, welding can be begun.

For non-synergic mode can set:

Wire Feed Speed, WFS

The

welding

voltage

Burnback

Time

Run-in

WFS

Preflow Time/ Postflow Time

Spot

Time

2-Step/4-Step

Start

Procedure

Crater

Procedure

Wave

Control:

Pinch

Welding GMAW and FCAW Process in

synergic mode CV

In synergic mode, the welding voltage is not set by user.

The correct welding voltage will set by the machine’s

software.

This value was recalled on the basis of data (input data)

had been loaded:

Wire Feed Speed, WFS.

If it is needed, the welding voltage can be adjusted by

the Right Control [36]. When the Right Control is rotated,

the display will show a positive or negative bar indicates

if the voltage is above or below the ideal voltage.

Additionally can manually set:

Burnback

Run-In

WFS

Preflow Time/ Postflow Time

Spot

Time

2-Step/4-Step

Start

Procedure

Crater

Procedure

Wave

Control:

Pinch

Welding SMAW Process

POWERTEC i380 ADVANCED

does not include the

electrode holder with lead necessary for SMAW welding,

but the one can be purchased separately.

Procedure of begin welding of SMAW process:

First turn the machine off.

Determine the electrode polarity for the electrode to

be used. Consult the electrode data for this

information.

Depending on the polarity of using electrode,

connect the work lead [13] and the electrode holder

with lead to output socket [3] or [4] and lock them.

See the Table 15.

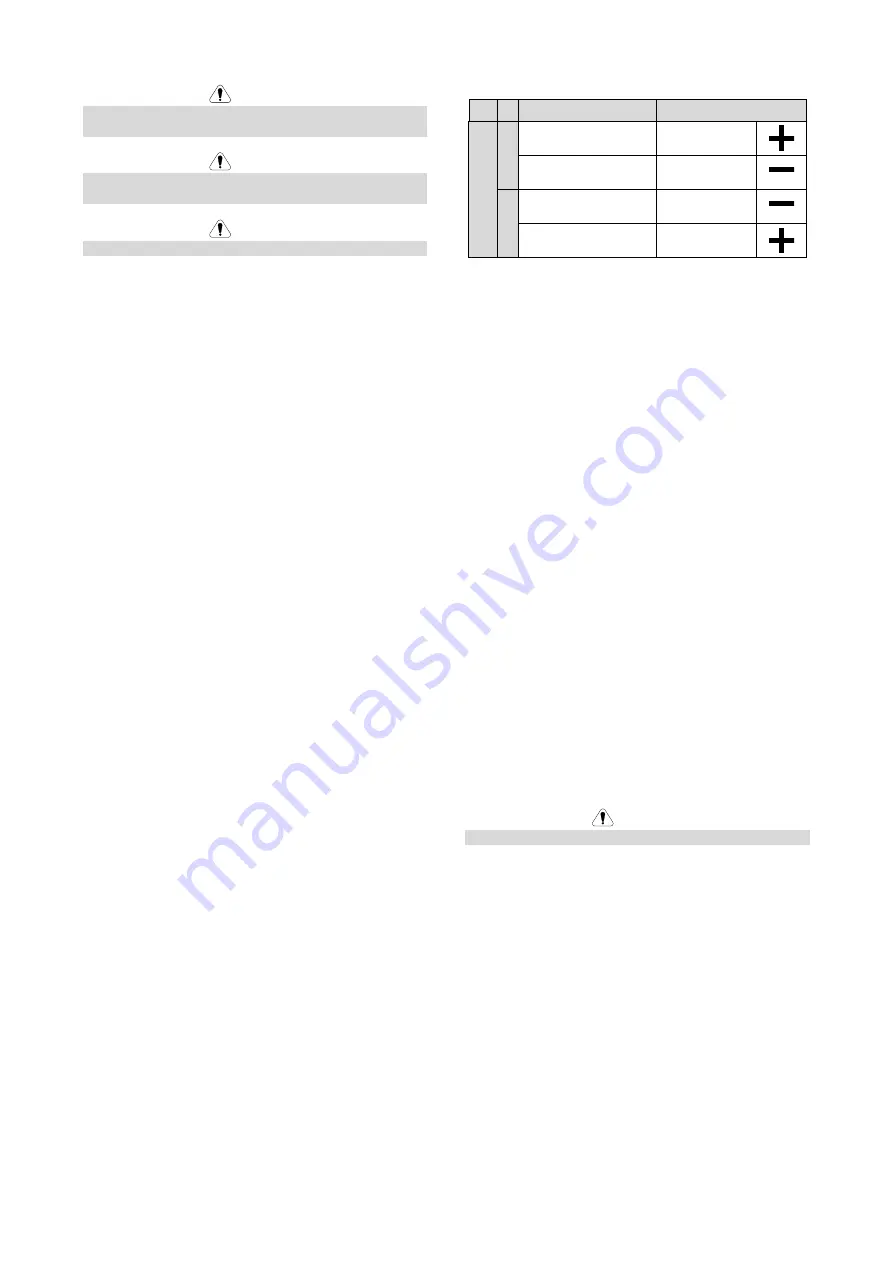

Table 15. Polarity

Output Socket

POLARITY

DC (+)

The electrode holder

with lead to SMAW

[4]

Work lead

[3]

DC (+)

The electrode holder

with lead to SMAW

[3]

Work lead

[4]

Connect the work lead to the welding piece with the

work clamp.

Install the proper electrode in the electrode holder.

Turn the input power ON.

Set the SMAW welding program.

Set the welding parameters.

The welding machine is now ready to weld.

By applying the principle of occupational health and

safety at welding, welding can be begun.

For SMAW program can set:

Welding

current

Switch on / switch off the output voltage on the

output lead

Wave

Controls:

ARC

FORCE

HOT

START

Loading the Electrode Wire

Turn the machine off.

Open the Right panel of the machine.

Unscrew the locking nut of the sleeve.

Load the spool with the wire on the sleeve such that

the spool turns anticlockwise when the wire is fed

into the wire feeder.

Make sure that the spool locating pin goes into the

fitting hole on the spool.

Screw in the fastening cap of the sleeve.

Put on the wire roll using the correct groove

corresponding to the wire diameter.

Free the end of the wire and cut off the bent end

making sure it has no burr.

WARNING

Sharp end of the wire can hurt.

Rotate the wire spool anticlockwise and thread the

end of the wire into the wire feeder as far as the Euro

socket.

Adjust force of pressure roll of the wire feeder

properly.

Adjustments of Brake Torque of Sleeve

To avoid spontaneous unrolling of the welding wire the

sleeve is fitted with a brake.

Adjustment is carried by rotation of its Allen screw M8,

which is placed inside of the sleeve frame after

unscrewing the fastening cap of the sleeve.