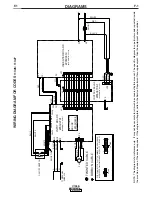

E-3

TROUBLESHOOTING

E-3

V155-S

If for any reason you do not understand the test procedures or are unable to perform the tests/repairs safely, contact your

Local Lincoln Authorized Field Service Facility

for technical troubleshooting assistance before you proceed.

Observe all Safety Guidelines detailed throughout this manual

PROBLEMS

(SYMPTOMS)

POSSIBLE

CAUSE

RECOMMENDED

COURSE OF ACTION

Oxidation

Tungsten inclusions

Porosity

Hot cracking

1. lnsufficient gas.

2. No protection on the back side.

1. lncorrect electrode sharpening.

2. Electrode too small.

3. Operating failure (contact of the

tip with the workpiece).

1. Dirt on the edges.

2. Dirt on the filler material.

3. Excessive travel speed.

4. Current intensity too low.

1 Unsuitable filler material.

2. High heat supply.

3. Dirty materials.

If all recommended possible areas of

misadjustment have been checked

and the problem persists,

Contact

your local Lincoln Authorized

Field Service Facility.

PROBLEMS IN TIG WELDING

If for any reason you do not understand the test procedures or are unable to perform the tests/repairs safely, contact your

Local Lincoln Authorized Field Service Facility

for technical troubleshooting assistance before you proceed.

CAUTION

Summary of Contents for INVERTEC V155-S 11326

Page 6: ...v SAFETY v EN 60974 10...

Page 7: ...vi SAFETY vi EN 60974 10...