20. CIRCUIT BREAKERS

These circuit breakers provide separate overload current

protection for each 120V circuit at the 240V single phase

receptacle, each 120V single phase receptacle, the 240V three

phase receptacle, the 120VAC in the 14-Pin connector, the

42VAC in the 14-Pin connector and battery circuit overload

protection.

21. 120VAC SINGLE PHASE RECEPTACLES

These two 120VAC (5-20R) receptacles with ground fault circuit

interruption protection provide 120VAC single phase for auxiliary

power. Each receptacle has a 20 amp total rating. They are

designed to protect the user from the hazards of ground faults.

When the GFCI has tripped there will be no voltage available

from the receptacle. Refer to the AUXILIARY POWER

RECEPTACLES section in the installation chapter for further

information about these receptacles. Also refer to the AUXILIARY

POWER OPERATION section later in this chapter.

22. GROUND STUD

Provides a connection point for connecting the machine case to

earth ground. Refer to “MACHINE GROUNDING” in the

Installation chapter for proper machine grounding information.

23. 240VAC THREE PHASE RECEPTACLE

This is a 240VAC (15-50R) receptacle that provides 240VAC

three phase auxiliary power. This receptacle has a 50 amp rating.

AIR COMPRESSOR CONTROLS (24 THRU 26)

24. COMPRESSOR ON/OFF SWITCH

Turns compressor on and off (standby) by opening and closing

the compressor inlet valve.

25. COMPRESSOR PROTECTION LIGHT

The yellow compressor protection light remains off with proper

compressor oil temperatures. If the lights turn on, the compressor

protection system will close the compressor inlet valve and put

the system in standby mode until the temperature reaches

allowable limits. Check for proper compressor oil level.

26. AIR DISCHARGE VALVE

Controls flow of compressed air. A 3/4” NPT (National Pipe

Thread) fitting is provided.

BATTERY JUMP START TERMINAL (27-28)

27. POSITIVE BATTERY JUMP START TERMINAL.

28. NEGATIVE BATTERY JUMP START TERMINAL.

12V battery jump start feature is standard. Covered output studs

for convenient access, and protection against accidental impact.

can be used to jump-start a utility truck with up to 800 cold

cranking amps. Can also be used to jump-start the AIR

VANTAGE® 500 Cummins.

29. BATTERY DISCONNECT SWITCH

Battery disconnect switch provides lockout/tagout capability.

Switch is conveniently located inside the engine compartment.

(SEE FIGURE B.2)

30. AIR CLEANER SERVICE INDICATOR

Air cleaner service indicator provides a Go/No-Go visual

indication of useful filter service life. Also located inside the

engine compartment. (SEE FIGURE B.2)

ENGINE OPERATION

STARTING THE ENGINE

1. Open the engine compartment door and check that the fuel

shutoff valve located to the left of the fuel filter housing is in the

open position (lever to be in line with the hose).

2. Make sure battery disconnect switch is in the on position.

3. Check for proper oil level and coolant level. Close engine

compartment door.

4. Remove all plugs connected to the AC power receptacles.

5. Set IDLER switch to “AUTO”.

6. Set the RUN/STOP switch to “RUN”. Observe that the engine

protection and battery charging lights are on. After 10 seconds,

the engine protection light will turn off.

7. Within 30 seconds, press and hold the engine START button

until the engine starts.

8. Release the engine START button when the engine starts.

9. Check that the engine protection and battery charging lights

are off. The engine protection light is on after starting, the

engine will shutdown in a few seconds. Investigate any

indicated problem.

10. Allow the engine to warm up at low idle speed for several

minutes before applying a load and/or switching to high idle.

Allow a longer warm up time in cold weather.

COLD WEATHER STARTING

With a fully charged battery and the proper weight oil, the engine

should start satisfactorily even down to about 0°F(-18°C). If the

engine must be frequently started below 10°(-12°C), it may be

desirable to install the optional ether start kit (K887-1). For

extreme cold conditions it may be desirable to install the Cold

Weather Heater and Tarp Kit (K2359-1). Installation and operating

instructions are included in the kits.

STOPPING THE ENGINE

1. Switch the RUN/STOP switch to “STOP”. This turns off the

voltage supplied to the shutdown solenoid. A backup shutdown

can be accomplished by shutting off the fuel valve located on

the fuel line.

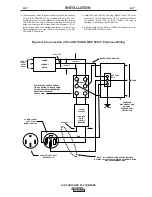

FIGURE B.2

B-5

OPERATION

B-5

AIR VANTAGE® 500 CUMMINS

30

29

Summary of Contents for AIR VANTAGE 500 CUMMINS

Page 37: ...F 2 DIAGRAMS F 2 AIR VANTAGE 500 CUMMINS CONNECTION DIAGRAM ...

Page 39: ...F 4 DIAGRAMS F 4 AIR VANTAGE 500 CUMMINS CONNECTION DIAGRAM ...

Page 40: ...AIR VANTAGE 500 CUMMINS F 5 DIAGRAMS F 5 CONNECTION DIAGRAM ...

Page 42: ...AIR VANTAGE 500 CUMMINS F 7 DIAGRAMS F 7 CONNECTION DIAGRAM ...

Page 43: ...AIR VANTAGE 500 CUMMINS F 8 DIAGRAMS F 8 CONNECTION DIAGRAM ...

Page 44: ...AIR VANTAGE 500 CUMMINS F 9 DIAGRAMS F 9 CONNECTION DIAGRAM ...

Page 45: ...AIR VANTAGE 500 CUMMINS F 10 DIAGRAMS F 10 CONNECTION DIAGRAM ...

Page 46: ...AIR VANTAGE 500 CUMMINS F 11 DIAGRAMS F 11 CONNECTION DIAGRAM ...

Page 47: ...AIR VANTAGE 500 CUMMINS F 12 DIAGRAMS F 12 CONNECTION DIAGRAM ...