Installation and Configuration

12

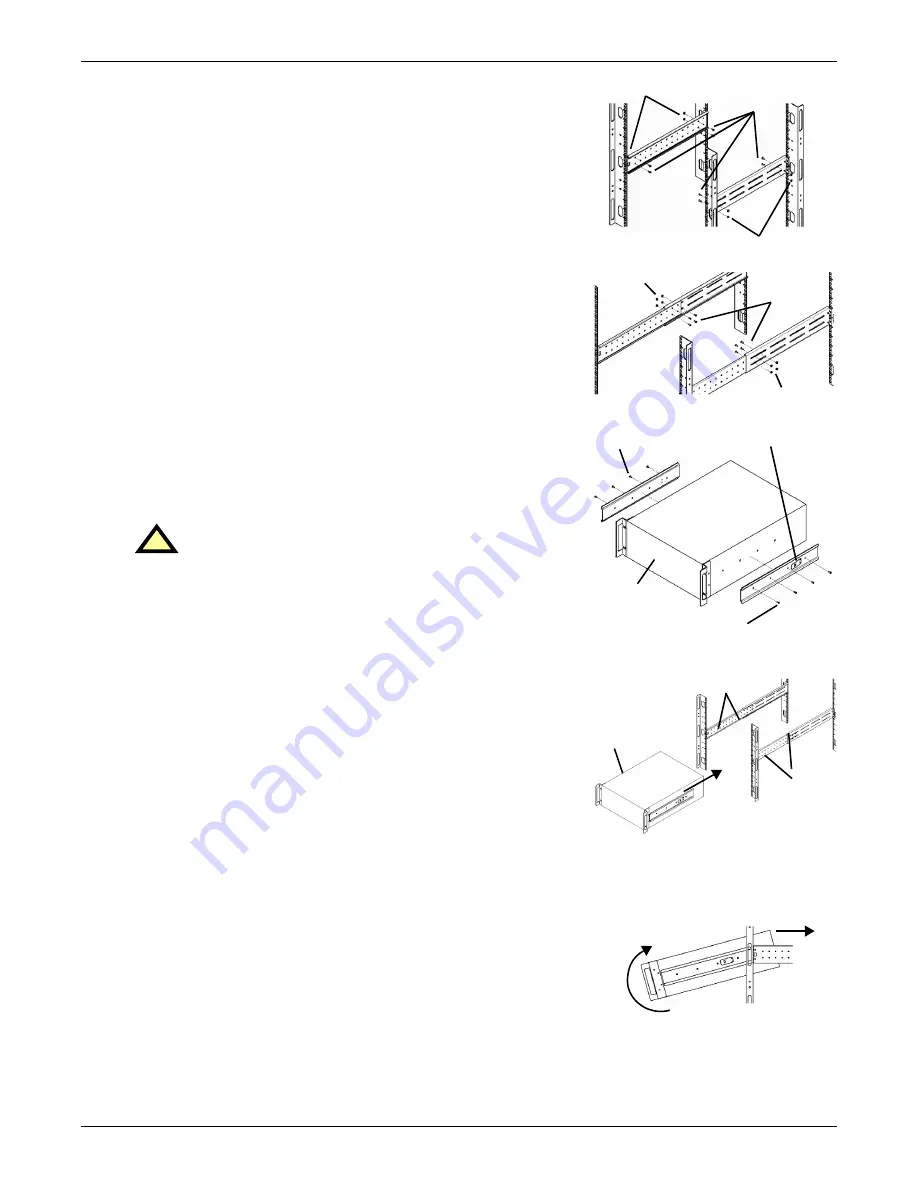

4. Get eight (8) M4 screws and eight (8) M4 nuts from the

hardware pack in this kit. Each nut has a locking, nylon

insert that begins gripping the screw when it is halfway

tight. Make sure to tighten the nut and screw completely to

ensure locking action. Fasten the rear member and the front

member together using (4) screws and (4) nuts per bracket

assembly as shown in at right. For maximum support, insert

fasteners for each bracket assembly as far apart as possible,

depending on rack depth, while still joining both members

(see figures at right). Check alignment of bracket assemblies

and TIGHTEN ALL SCREWS FROM

5. Prepare the UPS or battery cabinet (the “equipment”) for

rack mounting by following instructions in the equipment’s

user manual. The equipment may require additional parts to

be added or parts to be removed for rack mounting. After it is

prepared, lay the equipment in rack-mounting position.

Fasten the inner members from

to the equipment on

both sides as shown at right with eight (8) M4 screws

provided in the kit. Make sure retaining latch is near the rear

of the equipment as shown (see figure at right).

6. Open the grease packet provided in the kit. Apply a bead of

grease 25mm (1") long at four (4) places inside the bottom,

curved tracks of the front members as shown below right. The

grease will allow the equipment to slide into the bracket

assemblies more easily.

7. Insert the equipment, with inner members attached in

, into the bracket assemblies by inserting the top and

bottom edges of the inner members into the top and bottom

curved tracks of the front members and sliding the

equipment into the rack (see figure at right). Ends of inner

members are tapered to allow the rear of the equipment to be

angled upward before insertion, if space allows.

Then the rear, bottom edges of the inner members can be

placed into the front edge of the bottom tracks and the front

of the equipment can be tipped up so they are level to insert

the top edges of the inner members before sliding the equip-

ment into the rack (see figure below right). The equipment

should move smoothly into the bracket assemblies. If it does

not, recheck the alignment of the front and rear members

.

8. Secure the front of the equipment to the rack mounting rails

to prevent the equipment from sliding out of position. If

securing holes are provided on the front of the equipment

that align with the center holes on the return flange of the

front members, you can use the four (4) extra M5 screws

provided in the kit to secure the equipment. Otherwise, the

equipment should be secured to the front of the rack with

four (4) customer-supplied fasteners.

!

6.

CAUTION

Lifting equipment into the rack may be a two-person

job, depending on the weight of the equipment.

Liebert recommends taking the internal batteries

out of the UPS during rack installation. This will

make the UPS cabinet lighter and easier to handle.

The GXT2 weighs 67kg (151lb). For the battery

cabinet’s weight, see the unit’s user manual.

813mm

(32") rack

depth

M4 nuts

M4 nuts

M4

screws

457mm

(18")

rack

depth

M4 nuts

M4 nuts

M4

screws

UPS or battery

cabinet

Front

M4 screws

M4 screws

Retaining latch

UPS or

battery

cabinet

Apply

grease

(inside)

Apply

grease

Insert the UPS into the front

members, lift the front ...

... and push it

into the rack.

Summary of Contents for GXT2-4500RT230

Page 1: ...POWER AVAILABILITY GXT2 6000RT230 GXT2 4500RT230 USER MANUAL 230VAC...

Page 2: ......

Page 38: ...Specifications 34...

Page 39: ......