Fuses

Check the continuity of the fuse. With power OFF,

pull the fuse out of the fuse block. With the ohm-

meter on the R X 1 scale, measure resistance. A

reading of infinity indicates a blown fuse and must

be replaced. Replace fuse with same type, voltage

and amp rating.

Indicator Lights

If defective, replace all indicator pilot lights with

same type.

Magnetic Contactor

Contacts

- Check the contacts for severely burnt

or welded contacts. The contactor arm should

move freely.

Coil

- Measure the coil by disconnecting one of

the coil leads. Measure the coil resistance by set-

ting the ohmmeter on the R X 1 scale. A defective

coil will read zero or infinity, indicating a short or

opened coil respectively. Replace defective con-

tactor with same type.

NOTE:

Readings may vary depending on accuracy

of the measuring device.

Motor Protective Switch

Test by inserting a paper clip or other small device

into the test hole and push to the left. The relay

should trip.

Alarm Horn

Moving the alarm test/normal/silence switch to the

test position or activating the alarm float should

turn on the alarm horn. If the horn does not sound

replace with horn of same type.

Alarm Light

Moving the alarm test/normal/silence switch to the

test position or activating the alarm float should

turn on the alarm light. If the light does not activate,

replace with bulb of same type.

Float Controls

Check the floats during their entire range of opera

-

tion. Clean, adjust, or replace floats.

Checking the float resistance

- The float resis

-

tance can be measured to determine if the float

is operating correctly or is defective. Use the fol-

lowing procedure to measure the float resistance:

1.

Isolate the float by disconnecting one or both

of the float leads from the float terminals.

2.

Place one ohmmeter lead on one of the float

wires, and the other ohmmeter lead on the

other float wire.

3.

Place the ohmmeter dial to read ohms and

place on the R X 1 scale. With the float in the

“off” position, the scale should read infinity

(high resistance). Replace the float if you do

not get this reading. With the float in the ON

position, the scale should read nearly zero

(very low resistance). Replace the float if you

do not get this reading.

NOTE:

Readings may vary depending on the

length of wire and accuracy of the measuring

device.

Troubleshooting

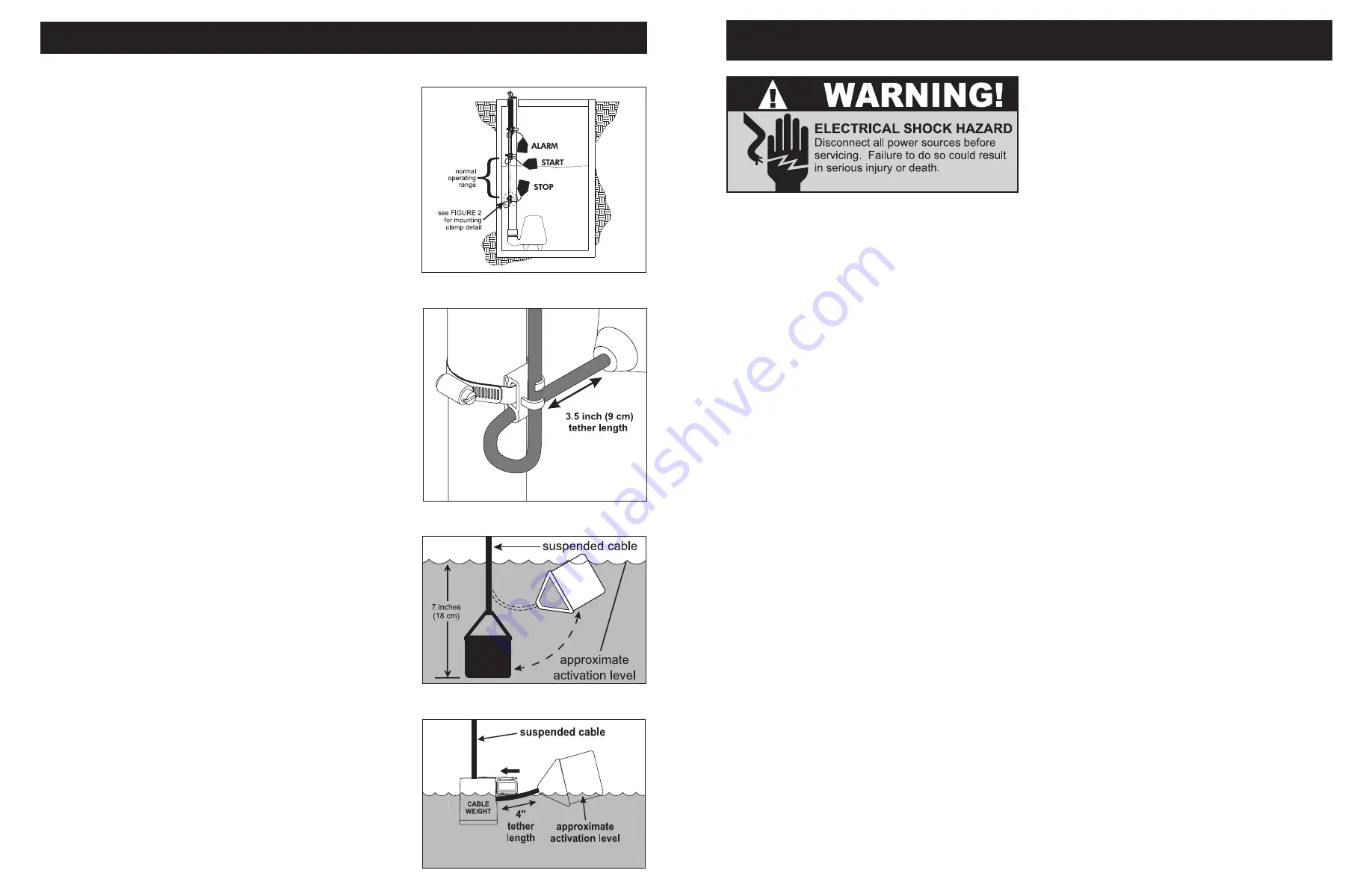

Installation of Floats

Standard three phase simplex panels are designed

to operate with three floats. These floats operate the

pump stop, pump start, and high level alarm functions.

NOTE: Options ordered may affect the number

of floats and their functions. Please reference

the schematic provided with the control panel for

proper installation.

CAUTION:

If control switch cables are not wired and

mounted in the correct order, the pump system will not

function properly.

WARNING:

Turn off all power before installing floats in

pump chamber. Failure to do so could result in serious

or fatal electrical shock.

1.

Use float label kit to identify and label cables on

both the float and stripped ends (stop, start, alarm,

etc.). See schematic for float options.

2.

Determine your normal operating level, as illustrated

in

Figure 1

.

3.

Mount float switches at appropriate levels as il

-

lustrated in

Figures 2-4

. Be sure that floats have

free range of motion without touching each other

or other equipment in the basin.

If using the mounting clamp; follow steps 4-6.

4.

Place the cord into the clamp as shown in

Figure

2

.

5.

Locate the clamp at the desired activation level and

secure the clamp to the discharge pipe as shown

in

Figure 2

.

NOTE:

Do not install cord under hose clamp.

6.

Tighten the hose clamp using a screwdriver. Over

tightening may result in damage to the plastic

clamp. Make sure the float cable is not allowed to

touch the excess hose clamp band during operation.

NOTE:

All hose clamp components are made

of 18-8 stainless steel material. See your SJE-

Rhombus

®

supplier for replacements.

Installation Instructions

FIGURE 4:

Float with cable weight

FIGURE 1:

Three float simplex -

pump down installation

FIGURE 2

: Mounting clamp detail

FIGURE 3:

Internally weighted float

- 2 -

- 5 -

7227000B

7227000B