8 | EN

Copyright © Liberty Pumps, Inc. 2021 All rights reserved.

5459000C

Maintenance

As the motor is oil-filled, no lubrication or other maintenance is

required. If replacement lubrication is required, use ISO VG 10

turbine oil. Use approximately 1.4 gallons to just cover the upper

bearing of the motor.

Severe operating environments will require more frequent checks.

For any issues that are not resolvable, contact Liberty Pumps for

further assistance.

Monthly

Pumps that are idle for more than a month in a dry basin should

have impellers manually operated through the breaker panel

monthly to lubricate the seals.

Pumps that are idle in a wet basin

must be removed.

Quarterly

1. Check pumps for corrosion and wear.

2. Check for free and unobstructed float switch operation and

float switch condition.

3. Inspect for proper check valve operation.

4. For multiple pumps, check for balanced operating times.

Uneven times indicate a defective unit, float switch or control.

5. Inspect the control panel for any presence of moisture in

enclosure, loose connections, and general component

condition.

Annually

1. Basin should be inspected and cleaned. Replace any defective

components.

Troubleshooting

No repair work shall be carried out during the warranty period

without prior factory approval. To do so may void the warranty.

Liberty Pumps, Inc. assumes no responsibility for damage or injury

due to disassembly in the field. Disassembly, other than at Liberty

Pumps or its authorized service centers, automatically voids

warranty.

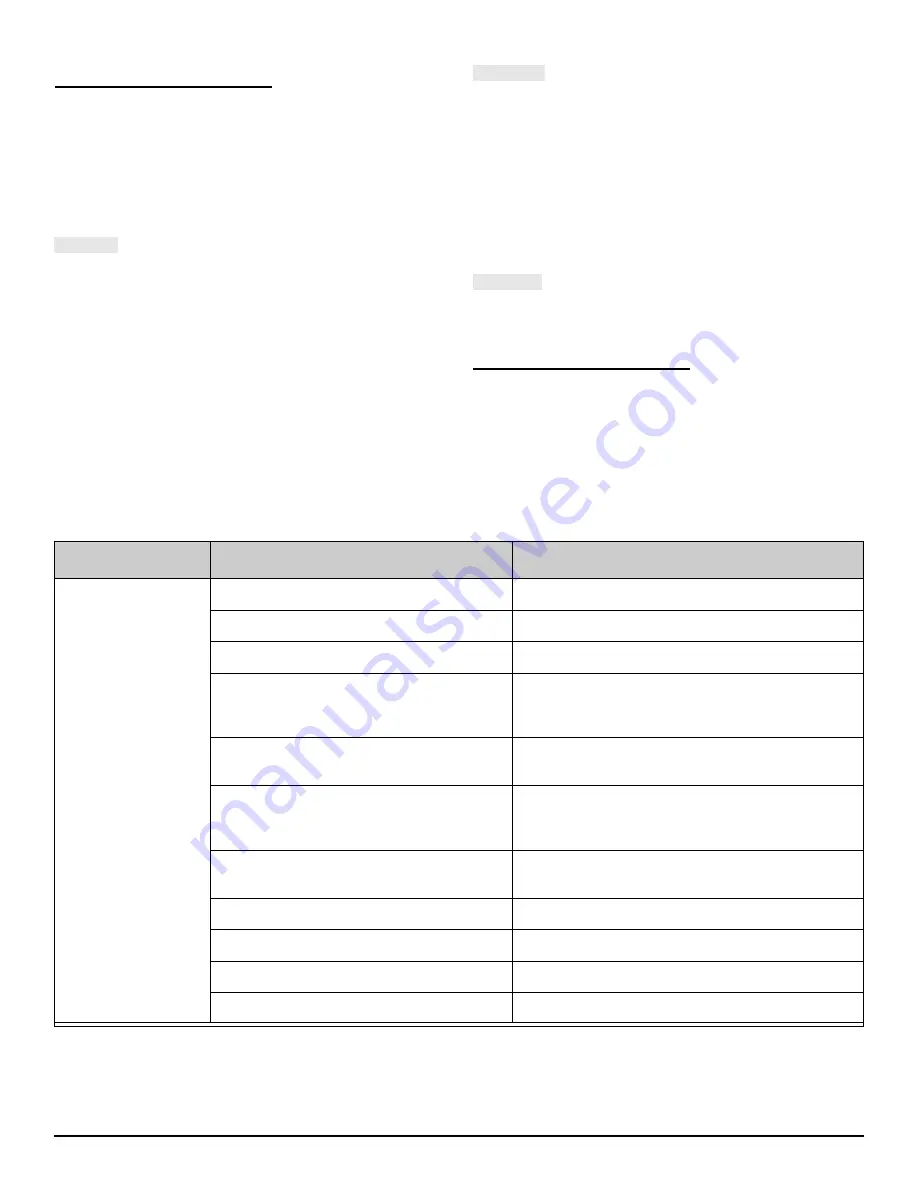

Table 2. Troubleshooting Matrix

Problem

Possible Cause

Corrective Action

Pump does not start.

Damaged power or control cord.

Replace as needed.

Control panel selector switch in OFF position.

Set selector switch to Hand or Auto position.

Blown control circuit transformer fuse.

Replace fuse.

Tripped circuit breaker, blown fuse, or other

interruption of power.

Reset tripped circuit breaker, replace blown fuse with

properly sized fuse, check that the unit is securely

plugged in, investigate power interruption.

Improper voltage.

Have an electrician check all wiring for proper

connections and adequate voltage and capacity.

Float switch unable to move to the pump ON

position due to interference in basin or other

obstruction.

Position the pump or float switch so that it has adequate

clearance for free movement.

Insufficient liquid level.

Verify the liquid level is allowed to rise enough to

activate float switch(es).

Defective float switch.

Replace float switch.

Obstructed impeller or volute.

Remove obstruction.

Loose wiring connections.

Check and tighten all connections.

Thermal overload tripped.

Wait for pump to cool to operating temperature.