1-5

No. DESCRIPTION

1500 3000 5000 6000 7500 9000 10000 12000 Test freatures

Specification

1

DRUM ASSY

RF out level

-4dB and below

2

ARM ASSY CLEANER

Wear status

3

MOTOR CAPSTAN (D-35)

W/F(WTD)

0.4% and below

4

BELT CAPSTAN

Belt tension

5

BASE ASSY A/C

-6dB and below

6

HEAD F/E

45dB min

7

ARM ASSY IDLER

4~12 g

8

HOLDER ASSY PINCH

60~90

9

BAND ASSY TENSION

Back Torque

40~70 g

10

HOUSING ASSY

CST loading status

11

CAPSTAN SOFT BRAKE

Felt wear

12

CLUTCHAY

Torque(Play, Rev)

there shouldn’t be any space

betwween CST and compartment

whether there is

touch noise

40~140gcm, 100~210gcm

1. Drum

Ass’y

Consists of video head, rotary trans and motor. records video and audio information on

the tape, and play the tape back.

(Audio information is recorded only on the Hi-Fi models)

2.

Arm Ass’y Cleaner

Cleans video head and rotation head automatically.

4.

Motor Capstan

Moves the tape with regular speed.

5.

Belt Capstan

Transfers rotative energy of capstan motor to the driving system.

6.

Brake Ass’y Capstan

Brakes rotative energy of capstan motor.

7.

Base Ass’y A/C

Consists of three head.

Audio erase head in the left upper erases audio signal in dubbing.

Audio head in the right upper records and playes the audio signal.

CTL head in the right lower records and detects CTL pulse to control tape speed.

8.

Head F/E

Is abbreviation of Full Erased Head.

erases the signal recorded on a tape clearly and absorb vibration of tape.

12. Arm Ass’y Idler

Is located between T/UP reel and supply reel.

Transfers ratative energy of capstan motor to T/UP reel or supply reel.

13. Holder Ass’y Pinch

Sticks a video tape to capstan motor and has the tape played without being

slipped from capstan motor axle.

14. Band Ass’y Tension

Has supply reel loosened properly with giving it some tensile force.

15. Arm Ass’y

Makes the cassette tape inserted be loaded and ejected precisly and safely.

16. Clutch Ass’y

Plays the tape with trasfering rotative energy of capstan motor to idler reel.

SECTION1 SUMMARY

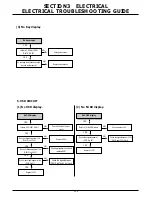

CRITICAL PARTS REPLACING TIME TABLE

Audio and CTL out

level

Whether extraneous

matters come out

Variation amount :

within 40%

The rate of erasing

(1KHz)

The capacity of ldler

for moving

Surrace solidity of

Roller

Reference :

Changing

Cleaning

Checking

Notes :

• Check the running path adjustment when you change the itens 1, 3, 5, 6 and 10.

• Check the back tension when you change Band Assy Tension.

CRITICAL PARTS DESCRIPTION

Summary of Contents for TL-AT130M

Page 23: ...3 14 3 13 SECTION3 ELECTRICAL BLOCK CIRCUIT DIAGRAMS 1 OVERALL WIRING DIAGRAM ...

Page 24: ...3 16 3 15 SECTION3 ELECTRICAL BLOCK CIRCUIT DIAGRAMS 2 POWER BLOCK DIAGRAM ...

Page 25: ...3 18 3 17 SECTION3 ELECTRICAL BLOCK CIRCUIT DIAGRAMS 3 POWER CLRCUIT DIAGRAM ...

Page 26: ...3 19 SECTION3 ELECTRICAL BLOCK CIRCUIT DIAGRAMS 4 AUDIO BLOCK DIAGRAM ...

Page 27: ...3 20 SECTION3 ELECTRICAL BLOCK CIRCUIT DIAGRAMS 5 Y C BLOCK DIAGRAM ...

Page 28: ...3 22 3 21 SECTION3 ELECTRICAL BLOCK CIRCUIT DIAGRAMS 6 A V CIRCUIT DIAGRAM ...

Page 29: ...3 23 SECTION3 ELECTRICAL BLOCK CIRCUIT DIAGRAMS ...

Page 30: ...3 25 3 24 SECTION3 ELECTRICAL BLOCK CIRCUIT DIAGRAMS 7 SYSTEM BLOCK DIAGRAM ...

Page 31: ...3 26 SECTION3 ELECTRICAL BLOCK CIRCUIT DIAGRAMS ...

Page 32: ...3 28 3 27 SECTION3 ELECTRICAL BLOCK CIRCUIT DIAGRAMS 8 SYSTEM CLRCUIT DIAGRAM ...

Page 33: ...3 30 3 29 SECTION3 ELECTRICAL BLOCK CIRCUIT DIAGRAMS 9 JACK CLRCUIT DIAGRAM ...

Page 34: ...3 32 3 31 SECTION3 ELECTRICAL BLOCK CIRCUIT DIAGRAMS 10 KEY BOARD CLRCUIT DIAGRAM ...

Page 35: ...3 34 3 33 SECTION3 ELECTRICAL PRINTED CIRCUIT DIAGRAMS 1 MAIN P C BOARD ...