2-36

Service Manual

4500–E220/E321/E323

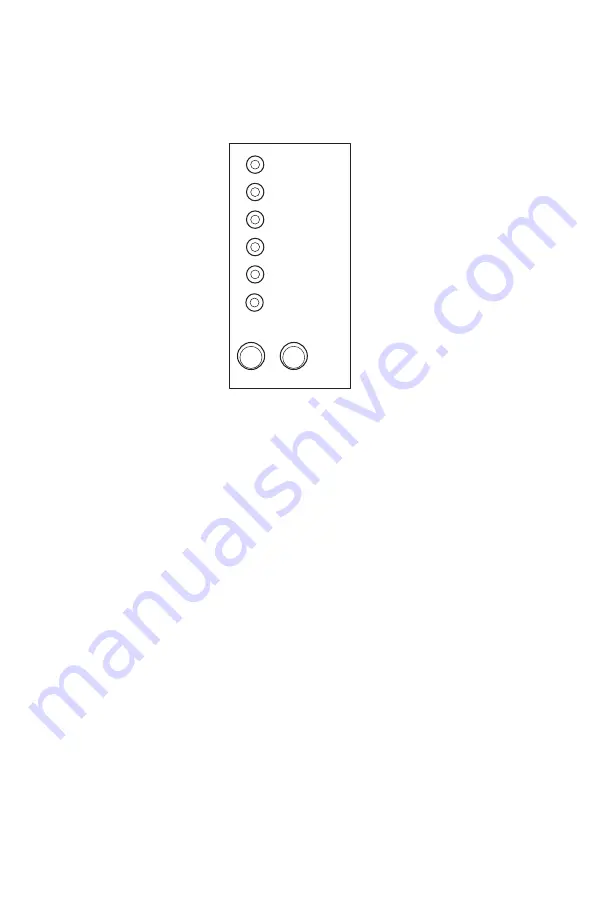

Operator panel

The operator panel consists of six indicator lights and two buttons.

Note:

Traditional printer settings such as paper source, paper size,

and orientation may not be selected or modified using the

operator panel with the exception that U.S. versus non–U.S.

may be chosen in the diagnostic mode. Users must either

utilize an application print driver and/or the printer toolkit to

modify settings.

The operator panel may be used for:

•

Determining printer status (See

for more information.)

•

Reviewing printer settings (See

for more information.)

•

Changing printer settings (See

for more information.)

•

Utilizing diagnostic tools (See

for more information.)

•

Obtaining information about printer service errors (See

“Service error codes ” on page 2-45

for more information.)

Error

Paper Jam

Load Paper

Toner Low

Ready/Data

Continue Cancel

Press Continue

Summary of Contents for 4500-00 Series

Page 14: ...xiv Service Manual 4500 Japanese laser notice Chinese laser notice...

Page 15: ...Laser notices xv 4500 Korean laser notice...

Page 16: ...xvi Service Manual 4500...

Page 21: ...Safety information xxi 4500...

Page 30: ...1 8 Service Manual 4500...

Page 174: ...3 38 Service Manual 4500 E220 E321 E323 Printer settings configuration...

Page 175: ...Diagnostic aids 3 39 4500 E220 E321 E323 Printer diagnostics...

Page 178: ...3 42 Service Manual 4500 E220 E321 E323...

Page 192: ...4 14 Service Manual 4500...

Page 204: ...5 12 Service Manual 4500 E220 E321 E323 wiring diagram...

Page 206: ...6 2 Service Manual 4500...

Page 208: ...7 2 Service Manual 4500 Assembly 1 Covers E320 E322...

Page 210: ...7 4 Service Manual 4500 Assembly 1 cont Covers E220 E321 E323...

Page 212: ...7 6 Service Manual 4500 Assembly 1 cont Covers E220 E321 E323...

Page 214: ...7 8 Service Manual 4500 Assembly 2 Frame 11 7 5 9 2 10 6 8 14 1 3 4 13 12...

Page 216: ...7 10 Service Manual 4500 Assembly 3 Fuser 7 12 10 1 2 3 4 6 8 9 5 11 11 8 7 5 6 6 5...

Page 218: ...7 12 Service Manual 4500 Assembly 4 Main drive...

Page 220: ...7 14 Service Manual 4500 Assembly 5 Paper feed 3 11 7 13 5 16 9 15 2 10 6 4 12 8 14 1 8 11 17...

Page 222: ...7 16 Service Manual 4500 Assembly 6 Printhead 8 5 2 1 3 6 4 7...

Page 224: ...7 18 Service Manual 4500 Assembly 7 Electronics 8 5 2 6 4 1 3 7...

Page 226: ...7 20 Service Manual 4500 Assembly 7 cont 8 5 2 6 4 1 3 7...

Page 228: ...7 22 Service Manual 4500 Assembly 8 Options 3 5 1 4 6 2...

Page 230: ...7 24 Service Manual 4500 Assembly 8 cont Options 3 5 1 4 6 2...

Page 234: ...7 28 Service Manual 4500...

Page 240: ...I 12 Service Manual 4500...