(BRANCH CIRCUIT)

WIRING

To connect motor for proper voltage and rotation, refer to connection diagram on nameplate or inside terminal/conduit box. If power factor

correction capacitors are used for individual motor power factor correction, do not exceed maximum recommended value.

All aspects of the installation must conform to the requirements of the NEC, including Article 430 (Motor Circuits and Controllers), and all

local codes. Wherever possible, each motor should be powered from a separate circuit of adequate capacity to keep voltage drop to a minimum during

starting and running. Increase wire size where motor is located a distance from the power source. Wire size must be adequate to minimize voltage drop

during starting and running. Refer to Tables A and B for suggested wire sizes. Distances shown are one-way between source and load. Portable cords, if

used, should be as short as possible to minimize voltage drop. Long or inadequately sized cords, especially on hard starting loads, can cause motor

failure. Insulate and protect motor lead connections to prevent cut-through from sharp edges and vibration. Tape wire nuts to prevent loosening. All

electrical connections in system must be secure to prevent voltage drop and localized heating.

Determine direction of rotation before connecting driven equipment to prevent damage. Remove shaft key if motor is to be operated at no-

load. On three phase motors, interchange any two line leads (not motor leads) to reverse rotation. On air compressors, rotation of flywheel should direct

air towards the cylinders. Look for rotational arrow on flywheel.

All motors must be securely and adequately grounded by wiring with a grounded, metal-clad raceway system, using a separate ground bond

wire connected to bare metal on the motor frame, or other suitable means. Refer to NEC Article 250 (Grounding) for additional information.

Explosion-proof motors incorporating overtempature thermostats should be controlled with a magnetic starter. The thermostat circuit must be

wired in series with the holding coil circuit, as shown on tag or nameplate on motor, to remove power from the starter coil if motor overheats.

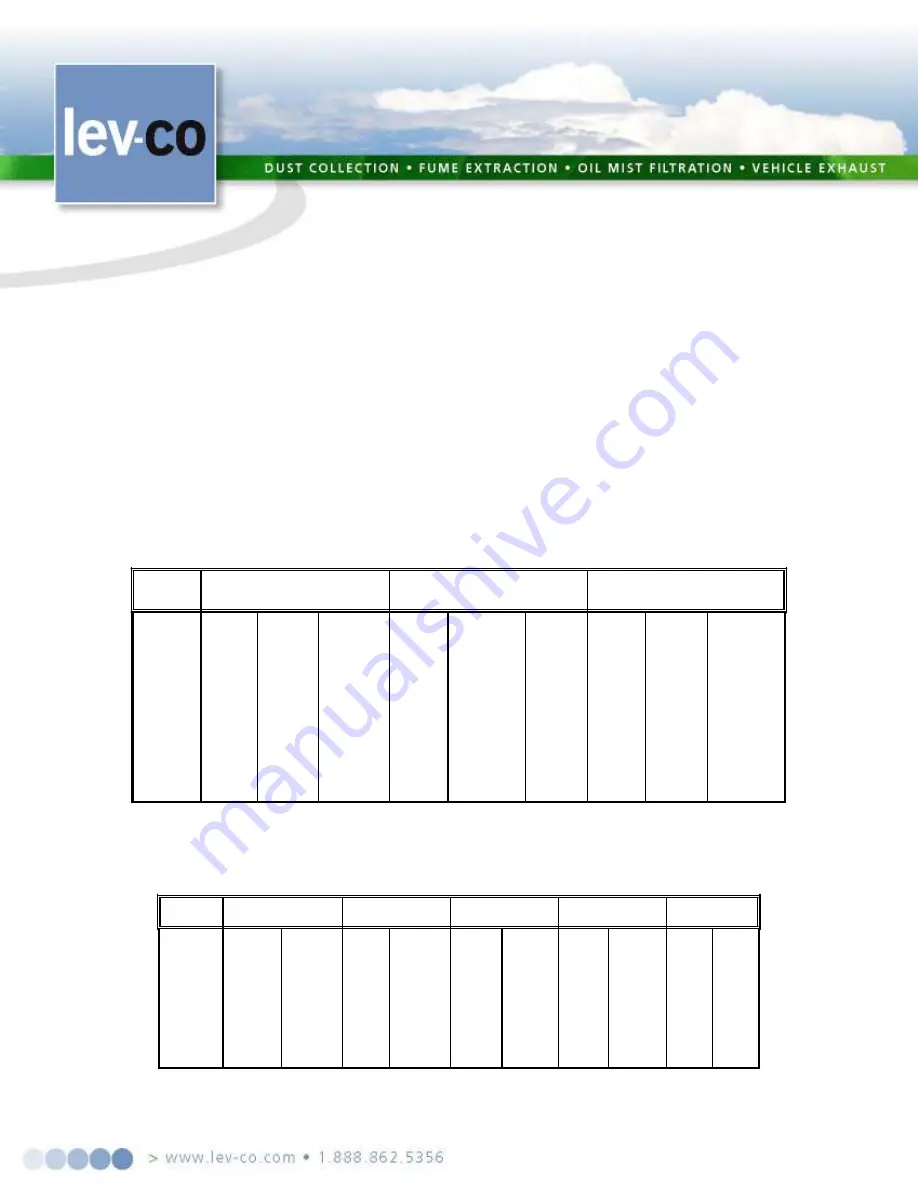

TABLE A - MINIMUM WIRE SIZES FOR THREE-PHASE MOTORS

[*]Type S, SO, SJ, SJO, etc. flexible cable wire sizes. See NEC Article 400 for ampacity

.

Note:

Above wire sizes based on approximate 5% voltage drop during starting; copper conductors; and 75°C type TH, THW, RH, RHW, etc. insulation. For aluminum

wire, increase two wire size steps minimum. See NEC Article 310 for ampacities of aluminum conductors and 60°C type RUW, T, etc. insulation

.

TABLE B - MINIMUM WIRE SIZES FOR SINGLE-PHASE MOTORS

[*] Type S, SO, SJ, SJO, etc. flexible cable wire sizes. See NEC Article 400 for ampacity.

Note:

Above wire sizes based on approximate 5% voltage drop during starting; copper conductors;and 75°C type TH, THW, RH, RHW, etc. insulation. For aluminum wire,

increase two wire size steps minimum. See NEC Article 310 for ampacities of aluminum conductors and 60°C type RUW, T, etc. insulation.

Page:

14/15 .

MOT0R

HP

25

FT

115V

230V

50

FT

115V

230V

100

FT

115V

230V

150

FT

115V

230V

200

FT

115V

230V

1/8

1/6

1/4

1/3

1/2

3/4

1

1½

2

3

14(16)*

14

14

14

14

12

10

10

8

8

14(18)*

14(18)*

14(18)*

14(18)*

14(18)*

14(18)*

14(16)*

14(16)*

14

10

14

12

12

10

10

8

8

6

6

4

14(18)*

14(18)*

14(18)*

14(16)*

14(16)*

14

14

12

12

10

10

10

8

8

8

6

4

4

3

2

14(16)*

14(16)*

14

14

14

12

10

10

8

8

10

8

6

6

6

4

4

2

2

1/0

14(16)*

14

12

12

12

10

8

8

6

6

8

6

6

4

4

3

2

1

1/0

2/0

14

12

12

10

10

8

8

6

6

4

MOTOR

HP

25 FT

TO

50 FT

200V

230V

460V

100 FEET

200V

230V

460V

150 FT

TO

200 FT

200V

230V

460V

1/8

1/6

1/4

1/3

1/2

3/4

1

1½

2

3

14(18)*

14(18)*

14(18)*

14(18)*

14(16)*

14

14

12

12

10

14(18)*

14(18)*

14(18)*

14(18)*

14(18)*

14(16)*

14(16)*

14

12

12

14(18)*

14(18)*

14(18)*

14(18)*

14(18)*

14(18)*

14(18)*

14(18)*

14(18)*

14(18)*

14(18)*

14(18)*

14(16)*

14(16)*

14

12

10

10

8

8

14(18)*

14(18)*

14(18)*

14(16)*

14

14

12

10

10

8

14(18)*

14(18)*

14(18)*

14(18)*

14(18)*

14(18)*

14(18)*

14(16)*

14(16)*

14

14(16)*

14(16)*

14

12

10

8

8

6

6

4

14(18)*

14(16)*

14

14

12

10

10

8

6

6

14(18)*

14(18)*

14(18)*

14(18)*

14(18)*

14(16)*

14

14

12

12

MOTOR WIRING GUIDE