4

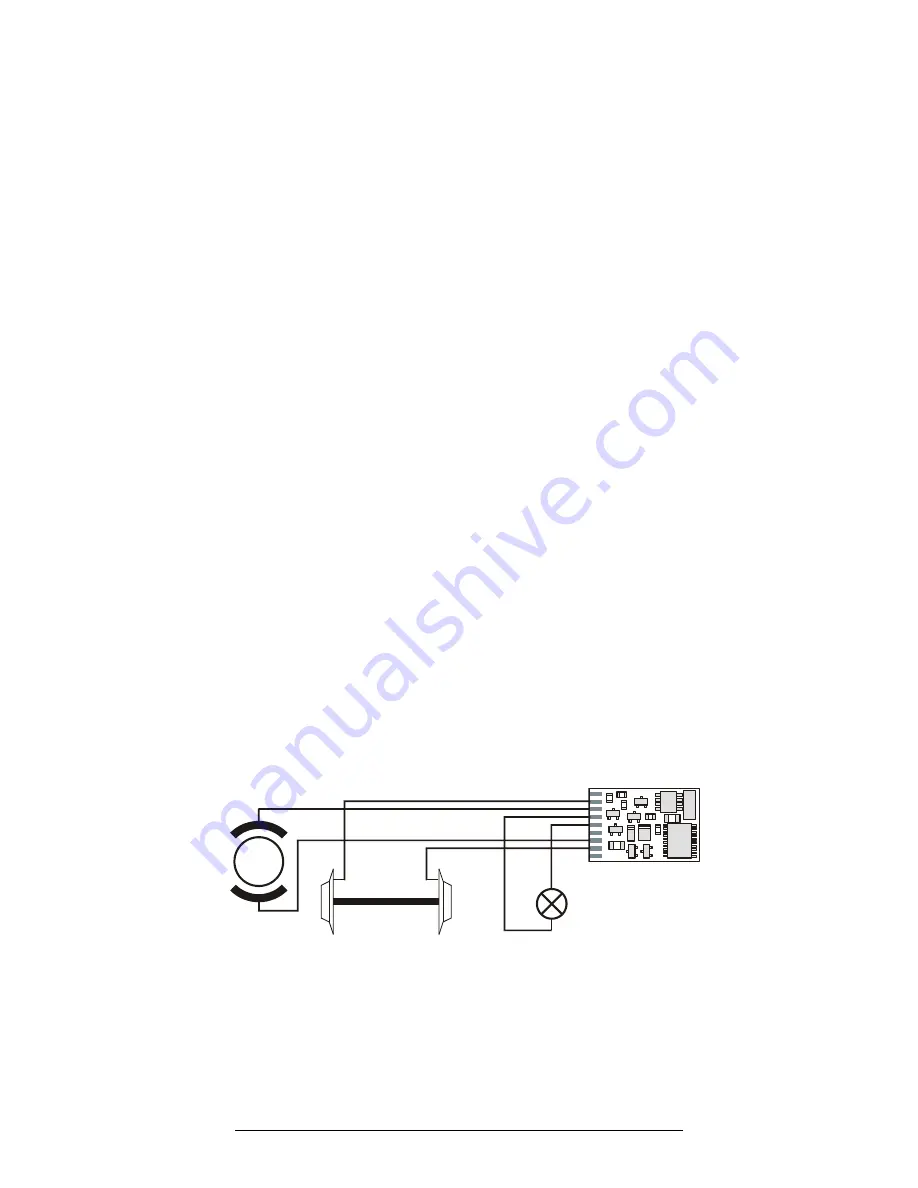

Wiring Instructions

First connect the decoder to the pick-ups from the wheels of the

locomotive:

•

red cable to the wheels, which in relation to the direction of

travel, are on the right-hand side of the locomotive

•

black cable to the wheels, which in relation to the direction of

travel, are on the left-hand side of the locomotive

Then connect the decoder to the motor connections:

•

orange cable to the motor connection previously connected to

the right-hand locomotive wheels

•

grey cable to the motor connection previously connected to

the left-hand locomotive wheels.

Now connect the function:

•

function output (white cable) to the bulb of the locomotive.

If the function inside the locomotive (e.g. the bulbs of the light) is

not electrically connected to the chassis of the locomotive (i.e; if

they are, "potential free") then connect the other pole of the

function to the blue cable, as shown in the illustration. If a

connection between functions and chassis does exist, then the

blue cable remains unused. When connected to the blue cable the

bulbs shine somewhat brighter. Which option you choose depends

on the design of the locomotive.

For the connection of LEDs note that the blue cable is the positive

pole (anode side of the LED) and the function output the negative

pole (cathode side of the LED). The voltage at the function output

is approximately 16 V. Please do not forget the necessary

protective resistor. The value of the resistor can be calculated by

the formula R = V/I where I is current rating of the LED and I is the

difference between the DCC track voltage and the voltage ratting

of the LED.

Motor

Orange

Grey

Red

Black

White

Blue

Wiring the LE1000A