Page 6

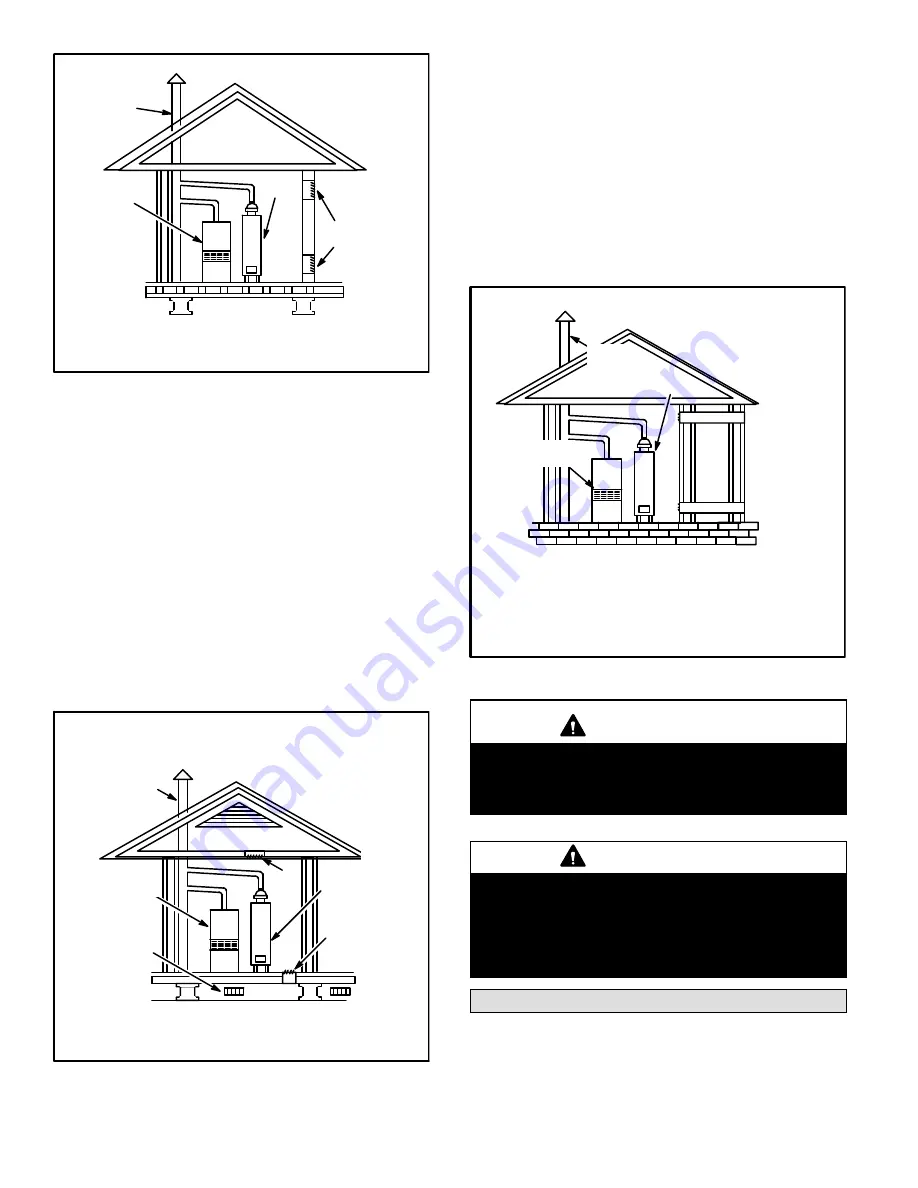

Equipment In Confined Space

All Air From Inside

Chimney or

Oil Ven

t

Water

Heater

Openings

(To Adjacent Room)

Figure 4

NOTE-Each opening shall have a free area of at least 1 square inch

(6.4 square centimeters) per 1,000 Btu (293 W) per hour of the total

input rating of all equipment in the enclosure, but not less than 100

square inches

(614.5 square centimeters).

Oil

Furnace

Air from Outside

If air from outside is brought in for combustion and ventila

tion, the confined space shall be provided with two perma

nent openings. One opening shall be within 12” (305 mm)

of the top of the enclosure and one within 12” (305 mm) of

the bottom. These openings must communicate directly or

by ducts with the outdoors or spaces (crawl or attic) that

freely communicate with the outdoors or indirectly through

vertical ducts. Each opening shall have a minimum free

area of 1 square inch (6.4 square centimeters) per 4,000

Btu (1172 W) per hour of total input rating of all equipment

in the enclosure. (See figure 5.) When communicating with

the outdoors through horizontal ducts, each opening shall

have a minimum free area of 1 square inch (6.4 square

centimeters) per 2,000 Btu (586 W) per total input rating of

all equipment in the enclosure (See figure 6).

Ventilation

Louvers

(For unheated

crawl space)

Outlet

Ai

r

Equipment In Confined Space

All Air From Outside

(Inlet Air from Crawl Space and Outlet Air to

Ventilated Attic)

NOTE-The inlet and outlet air openings shall each have a free area of at

least one square inch (6.4 square centimeters) per 4,000 Btu (1172 W)

per hour of the total input rating of all equipment in the enclosure.

Ventilation Louvers

(Each End Of Attic)

Water

Heater

Inlet

Air

Chimney or

Oil Vent

Figure 5

Oil

Furnace

When ducts are used, they shall be of the same cross-sec

tional area as the free area of the openings to which they

connect. The minimum dimension of rectangular air ducts

shall be no less than 3” (76 mm). In calculating free area,

the blocking effect of louvers, grilles, or screens must be

considered. If the design and free area of protective cover

ing is not known for calculating the size opening required, it

may be assumed that wood louvers will have 20 to 25 per

cent free area and metal louvers and grilles will have 60 to

75 percent free area. Louvers and grilles must be fixed in

the open position or interlocked with the equipment so that

they are opened automatically during equipment opera

tion.

Equipment In Confined Space

All Air From Outside

Outlet Ai

r

Inlet A

ir

Water

Heate

r

Chimney

Or Oil

Vent

Figure 6

NOTE-Each air duct opening shall have a free area of at least one

square inch (6.4 square centimeters) per 2,000 Btu (586 W) per hour of

the total input rating of all equipment in the enclosure. If the equipment

room is located against an outside wall and the air openings communi

cate directly with the outdoors, each opening shall have a free area of at

least one square inch (6.4 square centimeters) per 4,000 Btu (1172 W)

per hour of the total input rating of all other equipment in the enclosure.

Oil

Furnace

CAUTION

Combustion air openings in the front of the furnace

must be kept free of obstructions. Any obstruction

will cause improper burner operation and may re

sult in a fire hazard or injury.

WARNING

The barometric draft control must be removed from

the vent pipe when using a combustion air adapter.

Deviation from this practice will cause improper

burner operation and may allow flue products into

the living space which may result in personal injury

or death.

Locate & Level the Unit

Set the unit in desired location keeping in mind the clear

ances listed in table 2. Also keep in mind oil supply connec

tions, electrical supply, flue connections and sufficient clear

ance for installing and servicing unit.