Page 8

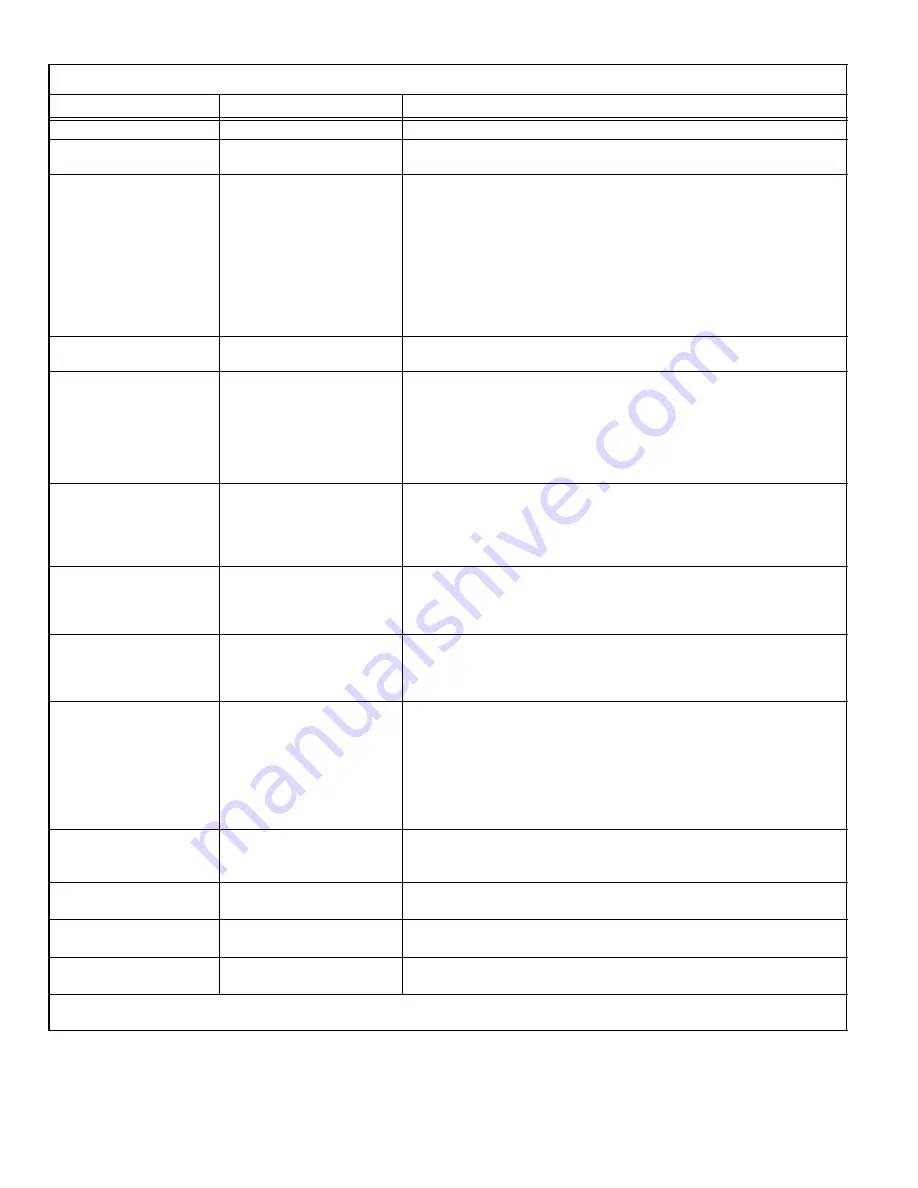

TABLE 4

System Operation Monitor LED Troubleshooting Codes

Status LED Condition

Status LED Description

Status LED Troubleshooting Information

Green Power" LED ON

Module has power

24VAC control power is present at the module terminal.

Green Power" LED OFF

Module not powering up

Determine/verify that both R and C module terminals are connected and

voltage is present at both terminals.

Red Trip" LED ON

System and compressor

check out OK

1.

Verify Y terminal is connected to 24VAC at contactor coil.

2.

Verify voltage at contactor coil falls below 0.5VAC when off.

3.

Verify 24VAC is present across Y and C when thermostat

demand signal is present; if not present, R and C wires are reversed.

Thermostat demand signal

Y1 is present, but compres-

sor not running

1.

Compressor protector is open.

2.

Outdoor unit power disconnect is open.

3.

Compressor circuit breaker or fuse(s) is open.

4.

Broken wire or connector is not making contact.

5.

Low pressure switch open if present in the system.

6.

Compressor contactor has failed to close.

Red Trip" & Yellow

Alert" LEDs Flashing

Simultaneous flashing.

Indicates that the control circuit voltage is too low for operation.

Yellow Alert" Flash

Code 1*

Long Run Time

−

Compressor is running

extremely long run cycles

1.

Low refrigerant charge.

2.

Evaporator blower is not running.

3.

Evaporator coil is frozen.

4.

Faulty metering device.

5.

Condenser coil is dirty

.

6.

Liquid line restriction (filter drier blocked if present)

.

7.

Thermostat is malfunctioning

.

Yellow Alert" Flash

Code 2*

System Pressure Trip

−

Discharge or suction pres-

sure out of limits or

compressor overloaded

1.

High head pressure.

2.

Condenser coil poor air circulation (dirty, blocked, damaged).

3.

Condenser fan is not running.

4.

Return air duct has substantial leakage.

5.

If low pressure switch is present, see Flash Code 1 info.

Yellow Alert" Flash

Code 3*

Short Cycling

− Compres-

sor is running only briefly

1.

Thermostat demand signal is intermittent.

2.

Time delay relay or control board is defective.

3.

If high pressure switch is present, see Flash Code 2 info.

4.

If low pressure switch is present, see Flash Code 1 info.

Yellow Alert" Flash

Code 4*

Locked Rotor

1.

Run capacitor has failed.

2.

Low line voltage (contact utility).

3.

Excessive liquid refrigerant in the compressor.

4.

Compressor bearings are seized.

Yellow Alert" Flash

Code 5*

Open Circuit

1.

Outdoor unit power disconnect is open.

2.

Unit circuit breaker or fuse(s) is open.

3.

Unit contactor has failed to close.

4.

High pressure switch is open and requires manual reset.

5.

Open circuit in compressor supply wiring or connections.

6.

Unusually long compressor protector reset time due to

extreme ambient temperature.

7.

Compressor windings are damaged.

Yellow Alert" Flash

Code 6*

Open Start Circuit

− Cur-

rent only in run circuit

1.

Run capacitor has failed.

2.

Open circuit in compressor start wiring or connections.

3.

Compressor start winding is damaged.

Yellow Alert" Flash

Code 7*

Open Run Circuit

− Current

only in start circuit

1.

Open circuit in compressor start wiring or connections.

2.

Compressor start winding is damaged.

Yellow Alert" Flash

Code 8*

Welded Contactor

−

Com-

pressor always runs

1.

Compressor contactor failed to open.

2.

Thermostat demand signal not connected to module.

Yellow Alert" Flash

Code 9*

Low Voltage

− Control cir-

cuit <17VAC

1.

Control circuit transformer is overloaded

.

2.

Low line voltage (contact utility).

*Flash code number corresponds to a number of LED flashes, followed by a pause, and then repeated. Reset ALERT flash code by

removing 24VAC power from monitor; last code will display for 1 minute after monitor is powered on.