Page 31

F-Compressor Controls

See unit wiring diagram to determine which controls are

used on each unit.

1- High Pressure Switch (S4, S7, S28, S96)

The compressor circuit is protected by a high

pressure switch which opens at 610 psig + 15 psig

(4206 kPa + 103 kPa) and automatically resets at 475

psig + 15 psig (3 103 kPa).

2- Low Pressure Switch (S87, S88, S97, S98)

The compressor circuit is protected by a loss of

charge switch. Switch opens at 40 psig + 5 psig (276

+ 34 kPa) and automatically resets at 90 psig + 5

psig (621 kPa + 34 kPa).

3- Crankcase Heater (HR1, HR2, HR5, HR11)

Units have compressors which contain a belly band

compressor oil heater which must be on 24 hours

before running compressors. Energize by setting

thermostat so that there is no cooling demand, to

prevent compressor from cycling, and apply power

to unit.

4- Freezestats (S49, S50, S53, S95)

Switches de-energize compressors when

evaporator coil temperature falls below 29

F (-2

C)

to prevent evaporator freeze-up. Switches reset

when evaporator coil temperature reaches 58

F

(15

C).

5- Low Ambient Pr. Sw. (S11, S84, S85, S94)

Switch maintains adequate discharge pressure by

de-energizing condenser fan when liquid pressure

falls below 240 psig +10 (1655 kPa+69). Switch

closes to energize condenser fan when pressure

rises to 450 psig +10 (3 69).

6- Thermal Protector (S5, S8, S31, S180)

The compressors used on 242H units are protected

by an external temperature switch. The n.c. switch

opens at 248

F + 9 (120

C + 5) and automatically

resets at 169

F + 18 (76

C + 10). The compressors

used on 300H and 360H units are protected by an

internal thermal protector switch.

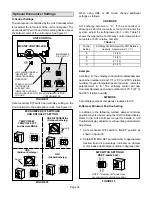

Condenser Fan Operation

Condenser fans 1, 2, and 3 are energized on a Y1

cooling demand; condenser fans 4, 5, and 6 are

energized on a Y2 cooling demand. Condenser fans

1, 2, 5, and 6 are energized after a 2 second delay.

See figure 22.

Condenser fans 2 and 5 are de-energized when

outdoor temperature drops below 55

F (13

C).

Condenser fans 1 and 6 are de-energized when

outdoor air temperature is below 40

F (4

C).

Condenser fan 3 is de-energized when both S11 and

S84 pressure switches (via K149) open due to low

pressure. S11 and S84 are located in refrigerant

circuits 1 and 2 respectively.

Condenser fan 4 is de-energized when both S85 and

S94 pressure switches (via K150) open due to low

pressure. S85 and S94 are located in refrigerant

circuits 3 and 4.

4

CONDENSER FAN CYCLING

FIGURE 22

COND.

FAN 4

K150

COND.

FAN 1

K10

COND.

FAN 6

K153

COND.

FAN 3

K149

COND.

FAN 5

K152

COND.

FAN 2

K68

1

2

3

Y1

Y2

S11 & S84

S85 & S94

55

F, 13

C

55

F, 13

C

40

F, 4

C

40

F, 4

C

EVAP COIL

K1

K2

K14

K146

Gas Heat Start-Up (Gas Units)

FOR YOUR SAFETY READ BEFORE LIGHTING

BEFORE LIGHTING smell all around the appliance area

for gas. Be sure to smell next to the floor because some

gas is heavier than air and will settle on the floor.

Use only your hand to push in or turn the gas control knob.

Never use tools. If the knob will not push in or turn by

hand, do not try to repair it, call a qualified service

technician. Force or attempted repair may result in a fire

or explosion.

This unit is equipped with an automatic spark ignition

system. There is no pilot. In case of a safety shutdown,

move thermostat switch to

OFF

and return the thermostat

switch to

HEAT

to reset ignition control.

WARNING

Danger of explosion. Can cause injury or

death. Do not attempt to light manually.

Unit has a direct spark ignition system.

WARNING

Electric shock hazard. Can cause injury

or death. Do not use this unit if any part

has been under water. Immediately call

a qualified service technician to inspect

the unit and to replace any part of the

control system and any gas control

which has been under water.