Page 10

Brazing Connection Procedure

1 − Cut ends of the refrigerant lines square (free from nicks

or dents). Debur the ends. The pipe must remain

round, do not pinch end of the line.

2 − Before making line set connections, use dry nitrogen to

purge the refrigerant piping. This will help to prevent

oxidation and the introduction of moisture into the sys-

tem.

3 − Use silver alloy brazing rods (5 or 6 percent minimum

silver alloy for copper−to−copper brazing or 45 percent

silver alloy for copper−to−brass or copper−to−steel braz-

ing) which are rated for use with HCFC−22 refrigerant.

Wrap a wet cloth around the valve body and the copper

tube stub. Braze the line set to the service valve.

4 − Wrap a wet cloth around the valve body and copper

tube stub to protect it from heat damage during braz-

ing. Wrap another wet cloth underneath the valve body

to protect the base paint.

NOTE − The tube end must stay bottomed in the fitting

during final assembly to ensure proper seating, sealing

and rigidity.

5 − Install a field−provided thermal expansion valve (ap-

proved for use with HCFC−22 refrigerant) in the liquid

line at the indoor coil.

Refrigerant Metering Device

H27 units are used in expansion valve systems only. See

the Lennox Engineering Handbook for approved TXV

match-ups and application information.

Expansion valves equipped with Chatleff fittings are avail-

able from Lennox. Refer to the Engineering Handbook for

applicable expansion valves for use with specific match-

ups.

If you install an expansion valve with an indoor coil that

includes a fixed orifice, remove the orifice before instal-

ling the expansion valve.

IMPORTANT

Failure to remove RFC orifice when installing an ex-

pansion valve on the indoor coil will result in improp-

er operation and damage to the system.

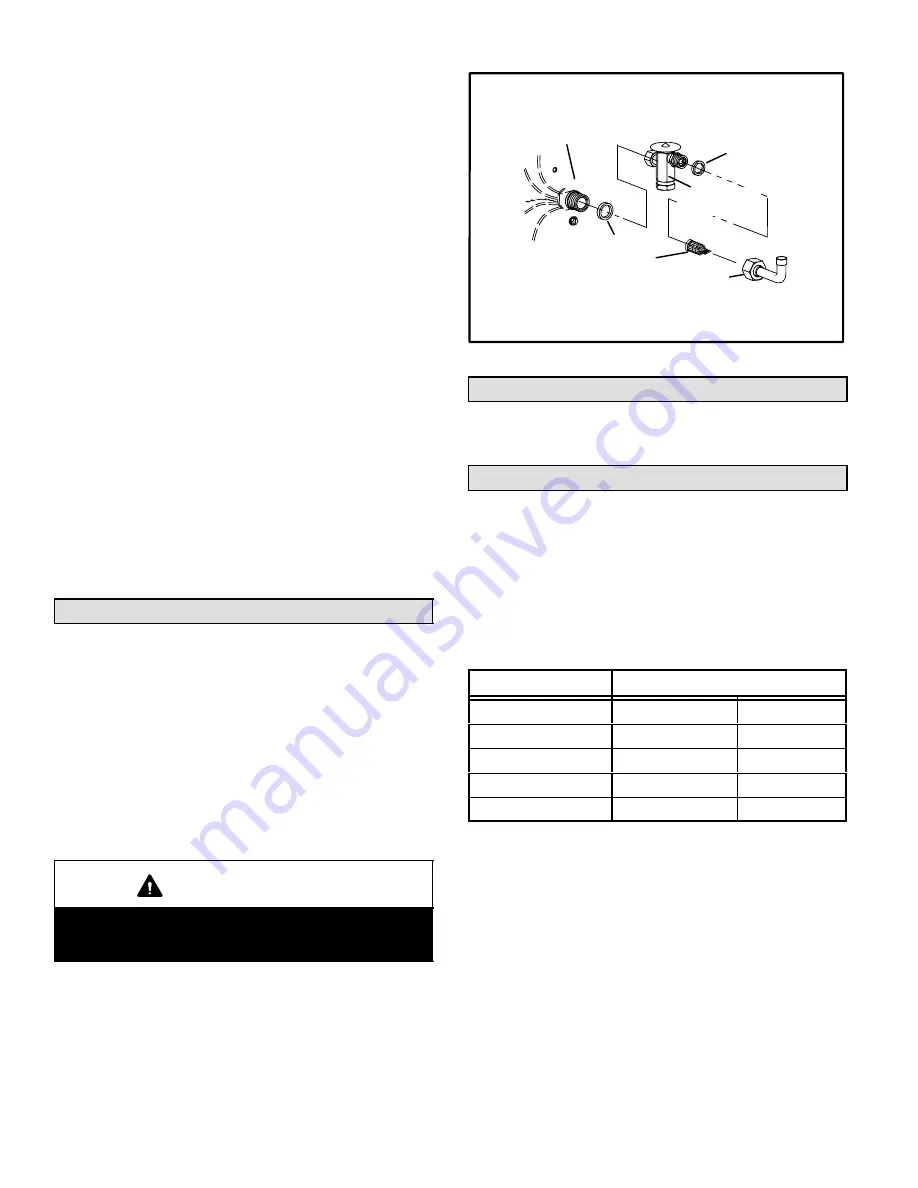

See figure 10 for installation of the check expansion valve.

Metering Device Installation

expansion

valve

o−ring

o−ring

strainer

liquid line

stub

distributor

Figure 10

Manifold Gauge Set

When checking the unit charge, use a manifold gauge set

that is equipped with low loss" hoses. Do not use a man-

ifold gauge set with anything other than a low loss" hose.

Service Valves

The liquid line and vapor line service valves (figures 11 and

12) and gauge ports are used for leak testing, evacuating,

charging and checking charge. See table 2 for torque re-

quirements.

Each valve is equipped with a service port which has a fac-

tory−installed Schrader valve. A service port cap protects

the Schrader valve from contamination and serves as the

primary leak seal.

Table 2

Torque Requirements

Part

Recommended Torque

Service valve cap

8 ft.− lb.

11 NM

Sheet metal screws

16 in.− lb.

2 NM

Machine screws #10

28 in.− lb.

3 NM

Compressor bolts

90 in.− lb.

10 NM

Gauge port seal cap

8 ft.− lb.

11 NM

To Access Schrader Port:

1 − Remove the service port cap with an adjustable wrench.

2 − Connect gauge to the service port.

3 − When testing is complete, replace the service port cap.

Tighten finger tight, then an additional 1/6 turn.

To Open Service Valve:

1 − Remove stem cap with an adjustable wrench.

2 − Use a service wrench with a hex−head extension to

back the stem out counterclockwise as far as it will go.