Page 13

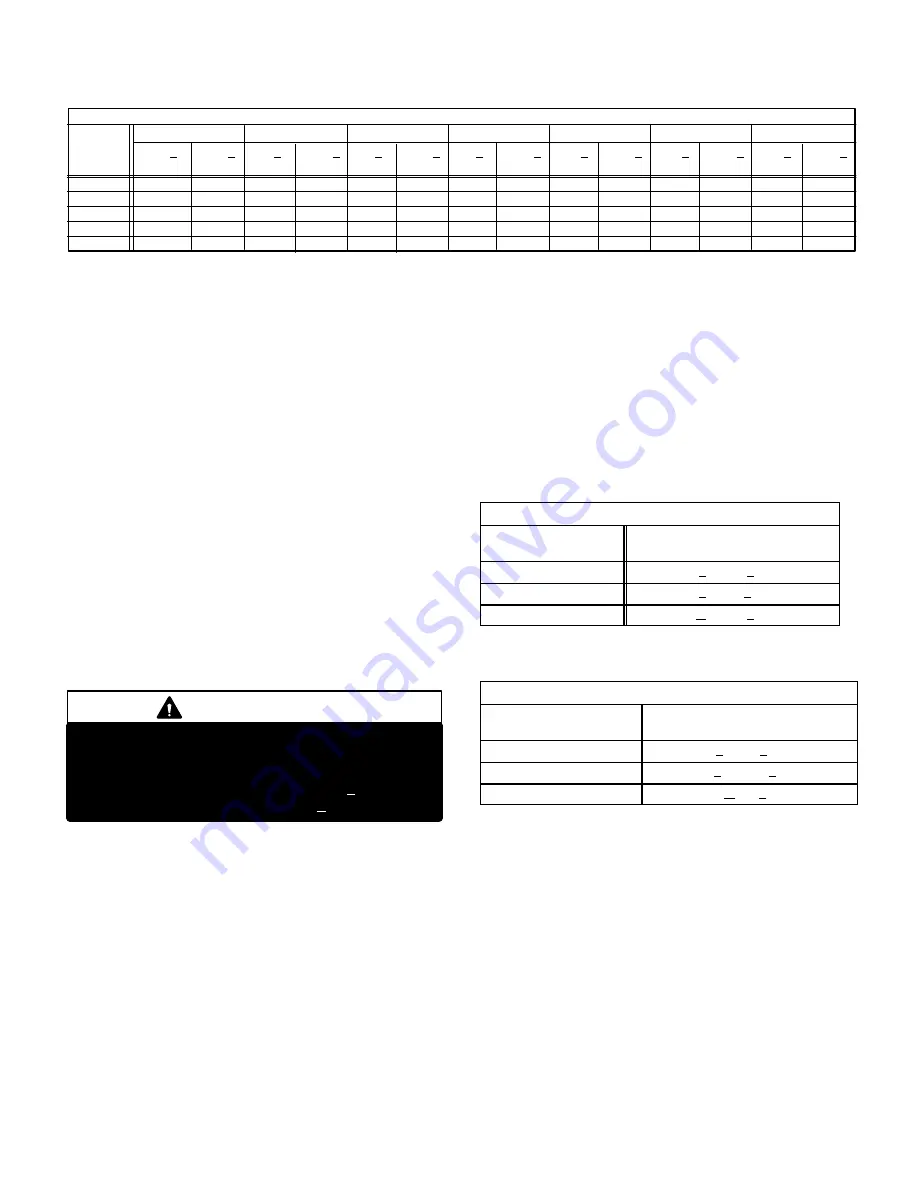

TABLE 10 (Late Models)

OUTDOOR

TEMP. (

_

F)

75

76

77

78

79

142

167

194

223

256

Suct.+

5 psig

Liq.+

10 psig

65

75

85

95

105

76

77

78

79

80

143

168

196

226

260

Suct.+

5 psig

Liq.+

10 psig

72

73

74

76

77

139

163

191

223

255

Suct.+

5 psig

Liq.+

10 psig

70

71

72

73

75

138

164

192

223

256

Suct.+

5 psig

Liq.+

10 psig

74

75

76

78

79

141

166

186

227

261

Suct.+

5 psig

Liq.+

10 psig

71

72

73

75

77

130

156

175

216

251

Suct.+

5 psig

Liq.+

10 psig

73

74

75

76

77

171

196

225

232

251

Suct.+

5 psig

Liq.+

10 psig

HS26−018

HS26−024

HS26−030

HS26−036

HS26−042

HS26−048

HS26−060

NORMAL OPERATING PRESSURES

If the system is completely void of refrigerant, the recom

mended and most accurate method of charging is to weigh

the refrigerant into the unit according to the total amount

shown on the unit nameplate. Also refer to the SPECIFI

CATIONS tables on page 1 for early model HS26 units and

page 2 for late model HS26 units.

If weighing facilities are not available or if unit is just low on

charge, the following procedure applies.

The following procedures are intended as a general guide

for use with expansion valve systems only. For best re

sults, indoor temperature should be between

70

°

F and 80

°

F. Outdoor temperature should be 60

°

F or

above. Slight variations in charging temperature and pres

sure should be expected. Large variations may indicate a

need for further servicing.

APPROACH METHOD (TXV SYSTEMS)

(Ambient Temperature of 60

_

F [16

_

C] or Above)

1− Connect gauge manifold. Connect an upright HCFC22

drum to center port of gauge manifold.

IMPORTANT

The following procedure requires accurate read

ings of ambient (outdoor) temperature, liquid tem

perature and liquid pressure for proper charging.

Use a thermometer with accuracy of +2

°

F and a

pressure gauge with accuracy of +5 PSIG.

2− Record outdoor air (ambient) temperature.

3− Operate indoor and outdoor units in cooling mode. Allow

units to run until system pressures stabilize.

4− Make sure thermometer well is filled with mineral oil be

fore checking liquid line temperature.

5− Place thermometer in well and read liquid line tempera

ture. Liquid line temperature should be a few degrees

warmer than the outdoor air temperature. Tables 11 and

12 show how many degrees warmer the liquid line tem

perature should be.

Add refrigerant to make the liquid line cooler.

Recover refrigerant to make the liquid line warmer.

TABLE 11

APPROACH METHOD − EXPANSION VALVES SYSTEM

MODEL

Liquid Line

_

F (

_

C) Warmer Than

Outside Ambient Temperature

H2−26−261,311

3 + 1 (1.6 + .5)

HS26−411

4 + 1 (2.2 + .5)

HS26−461

6 + 1 (3.3 + .5)

TABLE 12

APPROACH METHOD − EXPANSION VALVES SYSTEMS

MODEL

Liquid Line

_

F (

_

C) Warmer Than

Outside Ambient Temperature

HS26−036, 048

5 + 1 (2.8 + .5)

HS26−018, 030, 042, 060

8 + 1 (4.44 + .5)

HS26−024

9 + 1 (5+ .5)

6− When unit is properly charged liquid line pressures

should approximate those in table 9 or table 10.

D−Oil Charge

Refer to Table 1 and 2 on page 6.