Page 12

TABLE 4

KIT

CONTENTS

TUBE SHELF LIFE

10N46 − Refrigerant Analysis

Checkmate−RT700

10N45 − Acid Test Tubes

Checkmate−RT750A (three pack)

2 − 3 years @ room temperature. 3+

years refrigerated

10N44 − Moisture Test Tubes

Checkmate − RT751 Tubes (three

pack)

6 − 12 months @ room temperature. 2

years refrigerated

74N40 − Easy Oil Test Tubes

Checkmate − RT752C Tubes (three

pack)

2 − 3 years @ room temperature. 3+

years refrigerated

74N39 − Acid Test Kit

Sporlan One Shot − TA−1

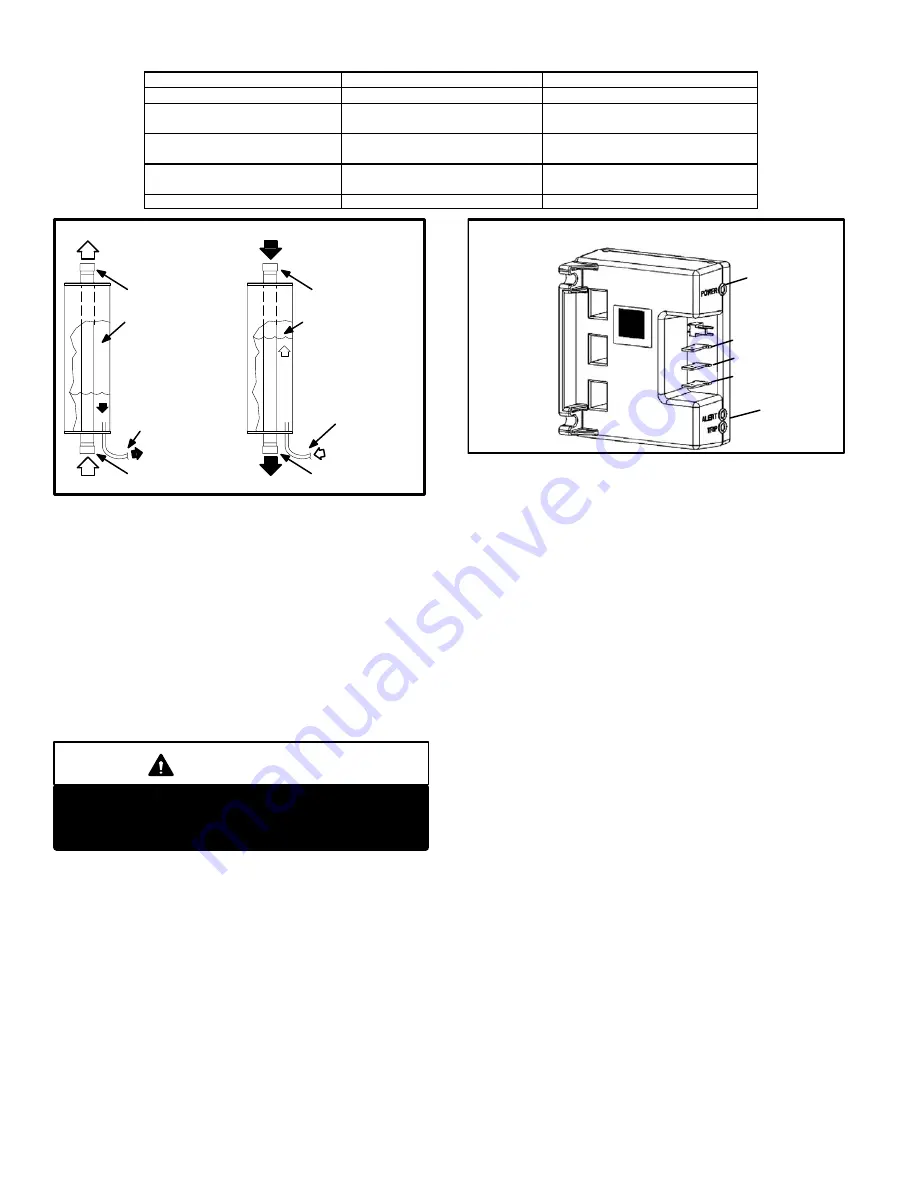

FIGURE 18

CHARGE COMPENSATOR OPERATION

During cooling mode, the va-

por line is hotter than the liq-

uid line. Stored liquid is

heated (boiled) and forced

back into circulation.

During heating mode, the va-

por line is cooler than the liq-

uid line. Excess refrigerant is

forced into the charge com-

pensator where it condenses

and collects.

Vapor Line

(To Outdoor Coil)

Vapor Line

(From Compressor Discharge Port)

Vapor Line

(From Outdoor Coil)

Vapor Line

(To Compressor Suction Port)

Stored Liquid

To Liquid Line

To be Circulated

Through Indoor Coil

Excess Refrigerant

To be Condensed and Stored

as Liquid

Compensator Tank

Compensator Tank

COOLING MODE

HEATING MODE

V−Lennox System Operation Monitor (A132)

The Lennox system operation monitor (LSOM) is a 24 volt

powered module wired directly to the indoor unit . See diag-

nostic module A132 on wiring diagram and figure 19. The

LSOM is located in the control box and is used to trouble

shoot problems in the system. The module has three LED’s

for troubleshooting: GREEN indicates power status, YEL-

LOW indicates an abnormal condition and RED indicates

thermostat demand, but compressor not operating. See

table 5 for troubleshooting codes.

IMPORTANT

The LSOM is not a safety component and cannot

shut down or control the HPXA19. The LSOM is a

monitoring device only.

W−Crankcase Heater (HR1)

Compressors in all units are equipped with a 70 watt belly-

band type crankcase heater. HR1 prevents liquid from ac-

cumulating in the compressor. HR1 is controlled by the

crankcaseheater thermostat.

X− Crankcase heater Thermostat (S40)

Thermostat S40 controls the crankcase heater in all units.

S40 is located on the liquid line. When liquid line tempera-

ture drops below 50° F the thermostat S40 closes energizing

HR1. The thermostat will open, de−energizing HR1 once liq-

uid line temperature reaches 70° F .

FIGURE 19

System Operation Monitor

Y

C

R

LE

D

LED’s

Y−Defrost System

The demand defrost controller uses basic differential tem-

perature means to detect when the system performs poor-

ly because of ice build−up on the outdoor coil. The control-

ler also uses self−calibrating" principles to calibrate itself

when the system starts and after every time the system

defrosts. The control board has the following compo-

nents: defrost relays, anti−short cycle timed−off control,

pressure switch/safety control, 5−trip lockout circuit, test

mode pins, ambient and coil temperature sensors, field

selectable termination temperature pins, and a field low

voltage connection terminal strip. See figure 20.

The control monitors ambient temperature, outdoor coil

temperature and total run time to determine when a de-

frost cycle is required. Two temperature probes are per-

manently attached to the control. The coil temperature

probe is designed with a spring clip to allow mounting to

the outside coil tubing. The location of the coil sensor is

important for proper defrost operation. See figure 21 for

coil sensor location. The ambient temperature sensor is

located in the PVC tube next to the filter drier.

NOTE − The logic of the demand defrost board accurately

measures the performance of the system as frost accumu-

lates on the outdoor coil. This typically will translate into

longer running time between defrost cycles as more frost

accumulates on the outdoor coil before the board initiates

defrost cycles.