506307-01

Page 17 of 36

Issue 1207

STARTUP AND OPERATIONAL CHECKOUT

Do not use this furnace as a construction heater. Use of

this furnace as a construction heater exposes the furnace

to abnormal conditions, contaminated combustion air and

the lack of air filters. Failure to follow this warning can

lead to premature furnace failure and/or vent failure which

could result in a fire hazard and/or bodily harm.

WARNING

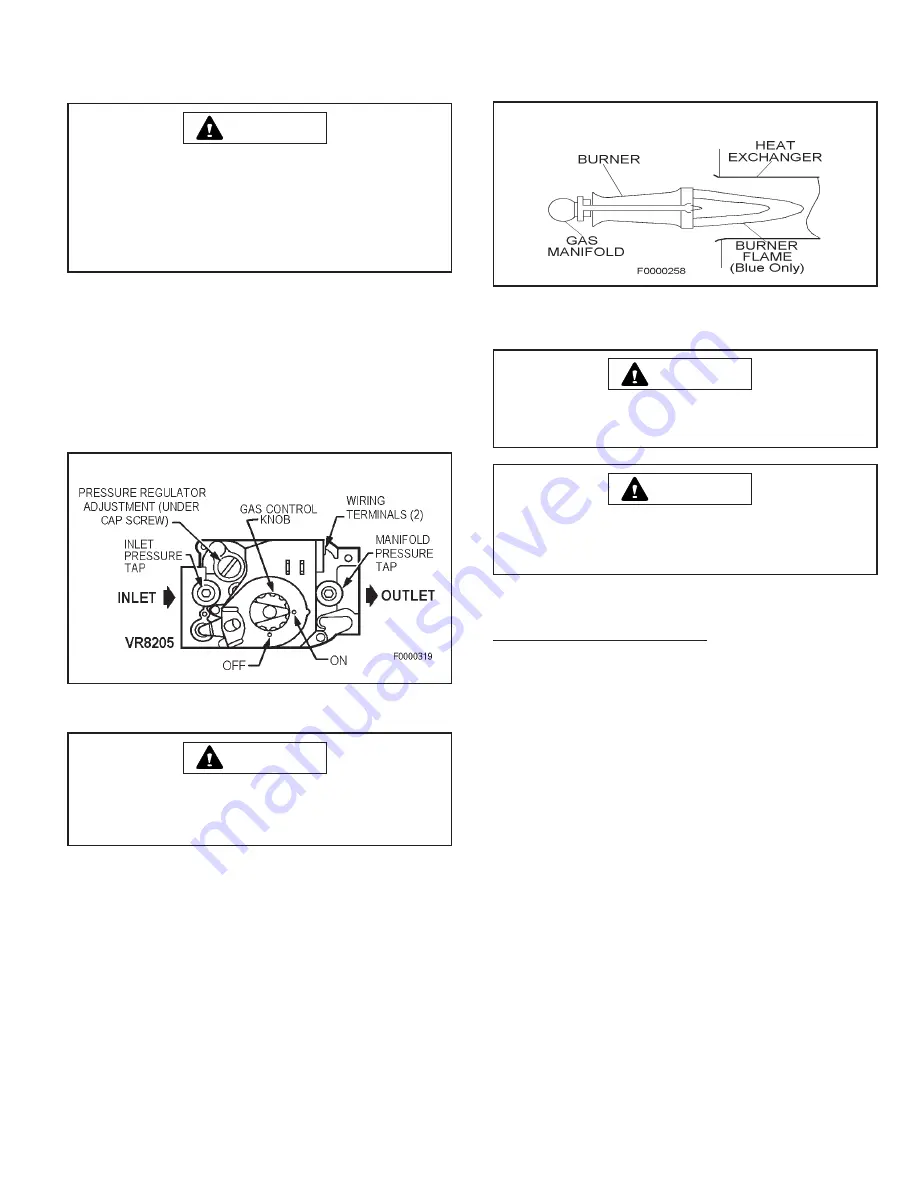

The automatic gas valve controls the flow of gas to the

main burners. The ignition system control switch built into

the automatic valve body has 2 positions: “OFF” and “ON”

(Figure 9). To shut off gas manually: Rotate switch from

“ON” to “OFF” position. When in “OFF” position, the main

burners are extinguished.

This furnace is equipped with an automatic spark ignition

control and does not require the manual lighting for furnace

operation.

GAS CONTROL DIAGRAM

Figure 9

After the ductwork connections have been made, gas

piping and electrical wiring completed and the furnace has

been properly vented, the unit should be started and adjusted

for proper operation. Check off the following steps as they

are completed.

1. Be sure all electrical power is OFF.

2. Check all wiring using proper wiring diagram on inside

of the control box cover.

3. Turn ON the electrical power.

4. Set the gas control knob in the “ON” position.

5. Set the thermostat above room temperaturae.

6. The ignitior will spark and the main burners will ignite.

Do not attempt to manually light the burners. Failure to

follow this warning can lead to electrical shock that could

result in bodily harm.

WARNING

TYPICAL FLAME APPEARANCE

(Main Burners)

7. Recheck for leaks in the manual shut off valve, gas control

valve and gas connections using a soap solution.

Never use an open flame when testing for gas leaks!

Use of an open flame could lead to a fire or explosion.

WARNING

Manifold Pressure Adjustment:

Turn OFF the gas and electrical before proceeding!

Remove the manifold pressure tap pipe plug from the gas

valve (Figure 9 outlet pressure tap) and install a pressure

tap and connect it to a manometer. Turn on the gas and

electrical supplies, then measure the manifold pressure

with

the furnace in operation.

Remove the cap to access the screw for input

adjustment (Figure 9 Pressure Regulator).

Turn regulator-

adjusting screw IN to increase pressure, OUT to

decrease pressure.

Replace the cap. Measure the

manifold pressure.

For natural gas, best results are obtained with a manifold

pressure of 3.2” to 3.5” w.c. For units that have been

converted to LP (Propane) gases, a manifold pressure of

10” w.c. is necessary. After proper adjustment, turn OFF

gas, replace manifold pressure tap pipe plug and turn ON

gas.

Many soaps used for leak testing are corrosive to certain

metals. Piping must be rinsed thoroughly with clean water

after leak check has been completed.

CAUTION

Summary of Contents for B050A3B

Page 3: ...506307 01 Page 3 of 36 Issue 1207...

Page 5: ...506307 01 Page 5 of 36 Issue 1207 FURNACE WIRING SPECIFICATIONS...

Page 23: ...506307 01 Page 23 of 36 Issue 1207 SEQUENCE OF OPERATION DIRECT IGNITION SYSTEM CONTROL...

Page 25: ...506307 01 Page 25 of 36 Issue 1207 WIRING DIAGRAM f0000321...