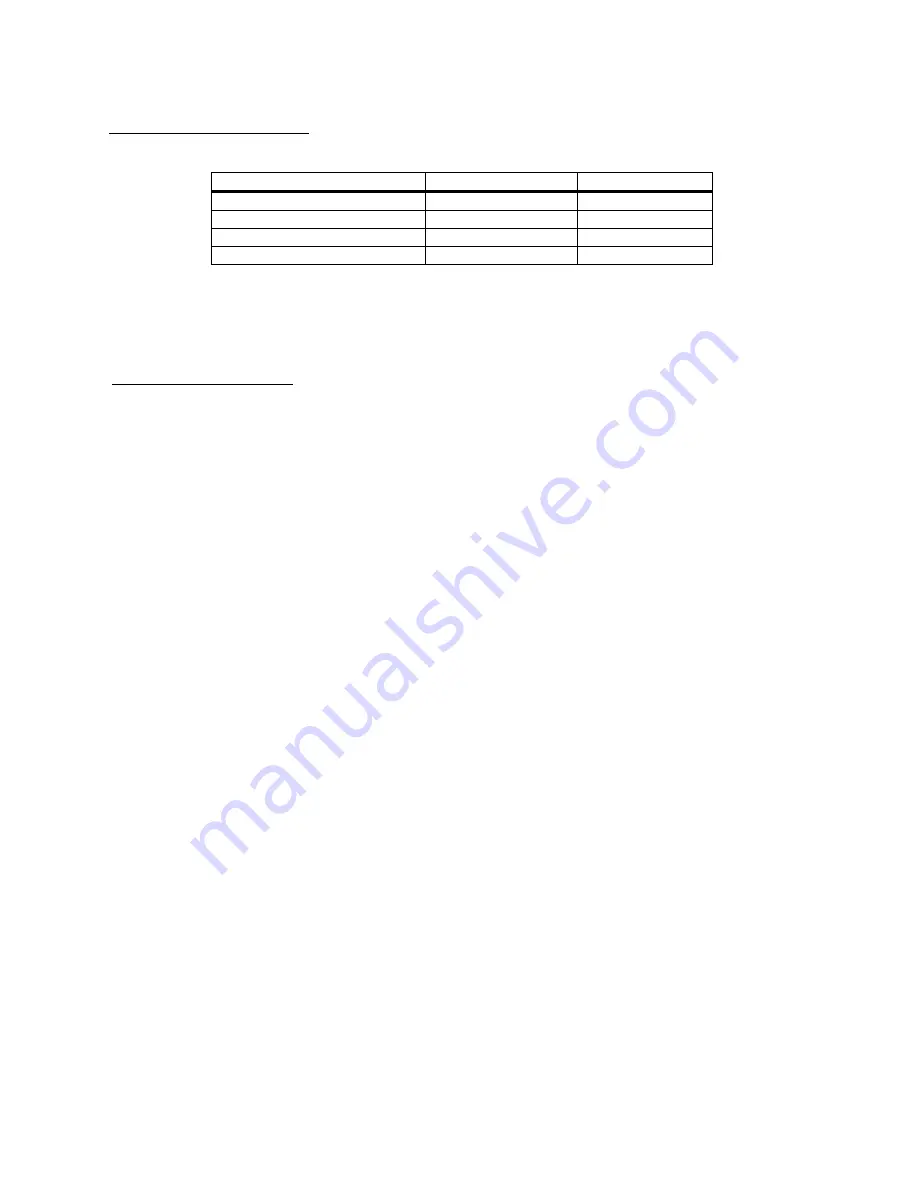

Options and Functions:

Function

Option

Action

Faults

None

Select

I/O Setup

None

Select

Voltages

None

Select-View Only

Neuron Version

None

View Only

Operation Examples:

Faults:

Press the

FUNC

button until “Faults” is displayed.

Press the

SEL

button until the curser is on the value to change (Clear, Mute, Fault number).

Use the up and down

arrows

to scroll through the fault list.

If the curser is on the Clear or Mute, the up or down arrow clears or mutes the fault.

The

OPT

button has no use for Faults.

I/O Setup:

Press the

FUNC

button until “I/O Setup” is displayed.

I/O number:

Press the

SEL

button until the curser is on the I/O number.

Use the up and down

arrows

to increment and decrement the I/O number.

I/O options:

Press the

SEL

button until the curser is on the I/O options.

Use the up and down

arrows

to change the I/O to Supervised, Normal, or Disabled.

Note: A Supervised input must include an EOL (end of line) resistor. A Normal input does not

need and EOL resistor.

Voltages:

Press the FUNC button until Voltages is displayed.

Press the

OPT

button to select the various voltages to display.

Note: Voltages cannot be changed, they can only be monitored.

Neuron Version:

Press the FUNC button until Neuron Version is displayed.

The Neuron version will be displayed.

8