innovators in agriculture

EN-15

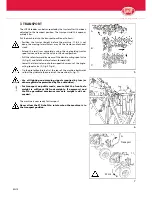

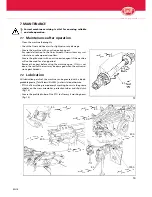

- Apply grease to all nipples on the machine (fig. 14).

When greasing the gearboxes, keep turning the rotors bit by bit

to ensure the grease is distributed effectively all over the gears.

7.3

Periodic maintenance

Periodic maintenance must be carried out:

• at the start of the haymaking season;

• before prolonged storage of the machine;

• when the machine is used extensively during the season.

- Grease all points of the machine listed in § 7.2 “Lubrication”.

- Grease the spring-loaded locking pins of the yoke lock of the PTO

shaft.

- Check if the PTO shafts telescope smoothly.

A damaged PTO shaft may cause excessive wear and tear to the

machine and tractor.

- Check the machine for any damage and flaws.

- Check the gearbox for any oil leaks.

(Changing of grease: see § 7.4.)

- Check the tyre pressure (fig. 15).

- Check all bolts and nuts for tightness.

Tighten loose bolts/nuts to the torques specified below.

- Check the rotors for sagging (fig. 16).

• Place the machine on a level floor.

• To adjust the outermost rotors, place the 6 central wheels on an

elevation of 30 mm; to adjust the second-to-most exterior rotor,

only the 4 central wheels need to be placed on an elevation.

• Ensure the machine is horizontal.

• The stop bolts (fig. 16) should then only just touch the stops.

M6

M8

M10

M12

M14

M16

M20

M24

Nm

10

25

50

85

135

215

410

710

kgm

1.0

2.5

5.0

8.5

13.5

21.5

41.0

71.0

15

275 kPa

150 kPa

100 kPa

(2.75 bar)

(1.5 bar)

(1.0 bar)

300 kPa

(3.0 bar)

16

30 mm