innovators in agriculture

EN-14

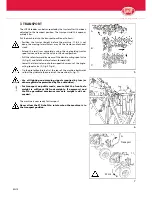

7 MAINTENANCE

• Correct machine servicing is vital for ensuring reliable

and safe operation.

7.1

Maintenance after operation

- Clean the machine thoroughly.

- Check the tines and tine arms for tightness or any damage.

- Grease the machine with an anti-corrosion agent.

Pay special attention to the tines. Smooth tines without any rust

stimulate an unhampered crop flow.

- Grease the piston rods with an anti-corrosion agent if the machine

will not be used for a long period.

Remove the agent before using the machine again. If this is not

done, the seals of the rams may be damaged when the anti-corro-

sion agent hardens.

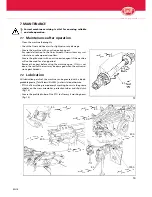

7.2

Lubrication

All lubrication points of the machine can be greased with a biode-

gradable grease (Total Biomultis SEP2), unless stated otherwise.

- PTO shafts must be greased every 8 working hours via the grease

nipples on the cross assemblies, protection tubes and slip clutch

(fig. 13).

- Grease the profiled tubes of the PTO shaft every 8 working hours

(fig. 13).

!

13

8 h

8 h

14

8 h

40 h

8 h

8 h

40 h

40 h

8 h

100 h