CONTROLLED COPY

Centre for Biological Engineering

Standard Operating Procedure

SOP194

Title: Use and maintenance of Leica RM2125 RTS rotary microtome.

Location:

H27

Version 001

Effective Date: 24.05.2021

Review 24.05.2023

Written by: Sotiria Toumpaniari

Reviewed by:

Approved by: C.Kavanagh

Page 9 of 11

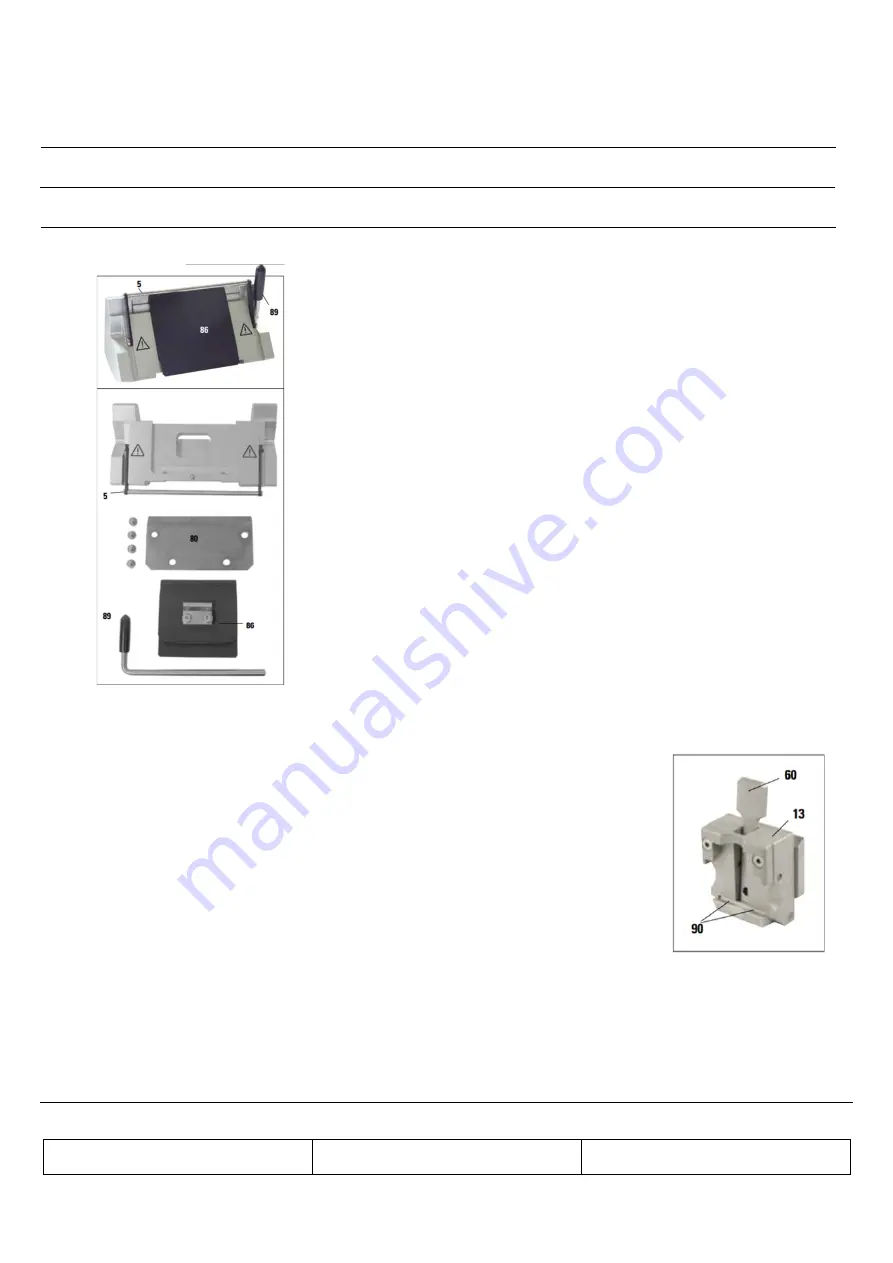

Knife holder E

Take the knife holder apart for cleaning. The front pressure plate can be

removed for cleaning. To do so, proceed as follows:

1.

Fold knife guard (5) downward.

2.

Rotate the blade clamping lever (89) downward.

3.

Carefully remove the blade and dispose of it properly.

4.

Pull out the clamping lever (89) sideways.

5.

Remove pressure plate (86).

6.

Clean all parts of the knife holder.

Note:

If several knife holders are cleaned at the same time, the parts must NOT be

mixed up! Failure to adhere to this may result in sectioning problems!

For cleaning and removal of paraffin, do not use xylene or cleaning fluids

containing alcohol (e.g. glass cleaner).

7.

Lay the removed parts on an absorbent cloth into the drying

chamber (up to a max. of 65 °C) and let the paraffin contamination run off.

Note: There is a burn hazard when removing the parts from the drying

chamber (65 °C). Wearing safety gloves is recommended!

8.

After cleaning the moving parts, apply a thin coat of drive part oil

to them.

9.

Reassembly takes place in reverse order.

10.

When performing the installation, make sure that the upper edge

of the pressure plate (86) is parallel and level with the upper edge of the

rear pressure plate (80). If necessary, adjust the pressure plates.

Universal cassette clamp

1. Detach cassette clamp (13) for a thorough cleaning, removing all

paraffin residues.

2. For cleaning, do not use xylene. Use xylene substitutes or paraffin

removers such as "Para Gard."

3. The cassette clamp (13) can also be placed in a drying chamber

heated to a maximum of 65 °C, until the liquid wax escapes.

Note:

There is a burn hazard when removing the parts from the drying chamber

(65 °C). Wearing safety gloves is recommended!

4. Remove paraffin residues with a dry cloth.

5. After such a cleaning procedure in an oven, always be sure to

lubricate the axle and spring of the clamping lever (60).

5.4.2. Maintainance

Note:

Only authorized and qualified service personnel may access the internal components of the

instrument for service and repair!

The instrument is basically maintenance-free. To ensure trouble-free operation of the instrument over a

long period of time, the following is recommended: