User Interface

SPRINTER 100/100M/200/200M

27

4.7.2

Entering Alphanumeric Values

Description

Alphanumeric fields can contain numeric as well as alphanumeric values e.g.: PtID.

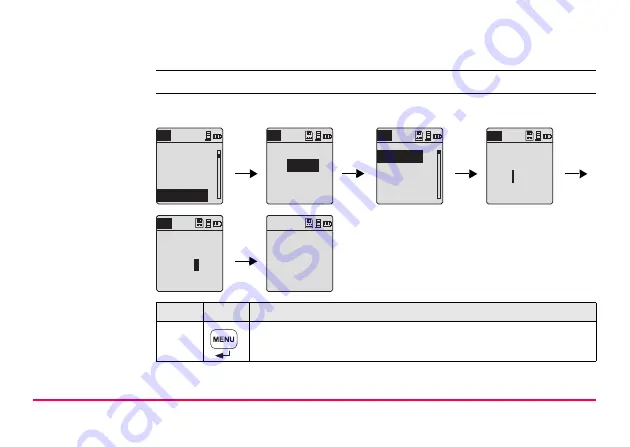

Initializing the alphanumeric Point ID (PtID) input with following steps:

Step

Key

Description

1.

Press Menu key to start menu for selection.

1. Input PtID

2. Input RL

3. Data Manager

4. Recording

MENU

RECORDING

Memory

Off

Ext.

MENU

1. Input PtID

2. Input RL

3. Data Manager

4. Recording

MENU

MENU

Enter Point No.

PtlD :

BM

1

MENU

Enter Point No.

PtlD :

BM1

PtlD

:

0.000

RL:

Meas. Reference

To change RL & ID

goto menu