7. Single Red Fash - (NO sanitizer is being produced)

being diverted away from the

A. Increase the flow rate above 15 gallons (56 LPM) per minute to activate

the flow detector.

A. The cell is scaled.

A. See # 2.

B.

C. Low salt

C. Check the residual salt level and adjust if necessary.

(Refer to the salt requirements needed for 3,000 ppm section, page 6).

D. The unit is no t reversing polarity.

D. Send the Control Panel to factory for service.

E. Possible cell failure. E. Refer to #4 of this section. If required, return

power and cell for testing/servicing.

F. Very cold pool water. F. Lower the output control dial setting, even to the "0"

position, and add a non -chlorine shock to the pool until the

water temperature increases above 60° F (14°C).

9. Triple CHECK SYSTEM flash

A. Low cell voltage.

10. Quadruple CHECK SYSTEM flash

A. No cell voltage or current.

15

5. White flakes in the water.

This occurs when excessive calcium hardness is present in the Monitor the pH and adjust if necessary.

water being purified. This should cease after a few days. (Refer to the Pool Water Preparation section, page 5.)

6. No OK light.

A. Incoming AC power for the main filter pump is not present. A. Ensure that the main filter pump circuit breaker is set to

"ON".

B. Power fuse blown B. Remove the knob and cover, replace this fuse.

PROBLEM

CAUSE

SOLUTION___________________________

A. There is NO FLOW or LOW FLOW to the flow detector.

B. Filter clogged or malfunctioning.

B. Check filter. Clean/backwash ore repair, as required.

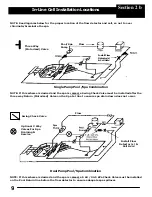

C. Flow detector is installed incorrectly (opposite the flow)

relation to the actual water flow.

C. Check flow detector and re-install properly.

D. The flow detector may have failed.

D. Replace the flow detector.

8.Double Red Flash - (Sanitizer IS still being produced)

B. The cell DC cord is disconnected from the cell.

B. Reconnect the DC cord properly.

A. Return cell for testing. Replace the cell if required.

A. Return control panel for testing/servicing.

Summary of Contents for 27315

Page 19: ......