- -

12

6

Troubleshooting

6 Troubleshooting

In the following chart the possible causes for an alarm are given together with their

solution

:

DEFAULT CAUSE

SOLUTION

RESTART

PROCEDURE

Alarm due to high

pressure of the

refrigerant

Lateral panels of

the housing open

Low airflow into

the condensor

The ambient

temperature is too

high

Water temperature

too high

Motor fan not

working

Close the panels

Clean the condensor

Wait until the ambient

temperature is lower

Try to cool down the

water in the circuit

running the chiller with

the application stopped

Check the motor fan

fuses. If the problem

persists contact

authorised technical

service.

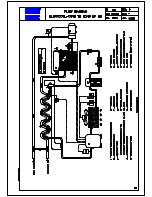

Disconnect the chiller

(On/Off and Main power

switch both Off, see point

4). Open the front panel of

the chiller and reset the

High-pressure safety

switch (SHP) by pressing

its button. Turn both the

Main power switch and the

On/Off switch back on.

Alarm due to low

pressure of the

refrigerant

Gas leakage

Contact authorised

technical service.

The Low-pressure safety

switch (SLP) automatically

resets itself when the

pressure is back to normal

Water level alarm

Water leakage

Check the water circuit

and refill the tank.

The level switch

automatically resets itself

when there is enough

water in the tank

UC-140 I

NDI

GO

50/

60Hz 29.

01.

03

rev

. 0