Initial Set-Up

Weight Transfer Springs

Initial Set-Up

Lastec//021819

3-11

3

3.12 Weight Transfer Springs

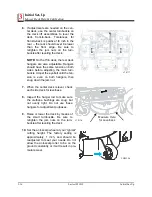

It is important that the weight transfer

system is operating properly. The weight

transfer springs help to lighten the

mower deck by transferring excess

weight to the drive unit. The elimination

of excess weight allows more agile float-

ing of the mower deck, resulting in a

higher quality cut and a lower incidence

of turf damage.

The weight transfer springs are located

under the operator seat pan, running

from the mounting bolt on the left front of

the frame to the anchor located on the pivot arm. The pivot arm extends to the outer left

and right of the frame.

Check to be sure that all weight transfer springs are properly mounted and secure. The

springs may come as close as one inch to the mounting bracket. Adjust the spring tension

by tightening the bolt at the rear of the springs.

Proper operation of the weight transfer system will allow you to lift the mowing deck by

the handle with little effort.

CM0035-3

Summary of Contents for 2561D

Page 1: ...2561D Articulator 2573D Articulator Owner s Manual Manual Part Man 2561D...

Page 6: ......

Page 7: ...Lastec 021819 1 1 1 SECTION 1 TO THE OWNER...

Page 15: ...Lastec 021819 2 1 2 SECTION 2 SAFETY INFORMATION...

Page 30: ......

Page 31: ...Lastec 021819 3 1 3 SECTION 3 INITIAL SET UP...

Page 49: ...Lastec 021819 4 1 4 SECTION 4 OPERATING PROCEDURES...