M

M

M

E

E

E

R

R

R

C

C

C

U

U

U

R

R

R

Y

Y

Y

U

U

U

S

S

S

E

E

E

R

R

R

M

M

M

A

A

A

N

N

N

U

U

U

A

A

A

L

L

L

44

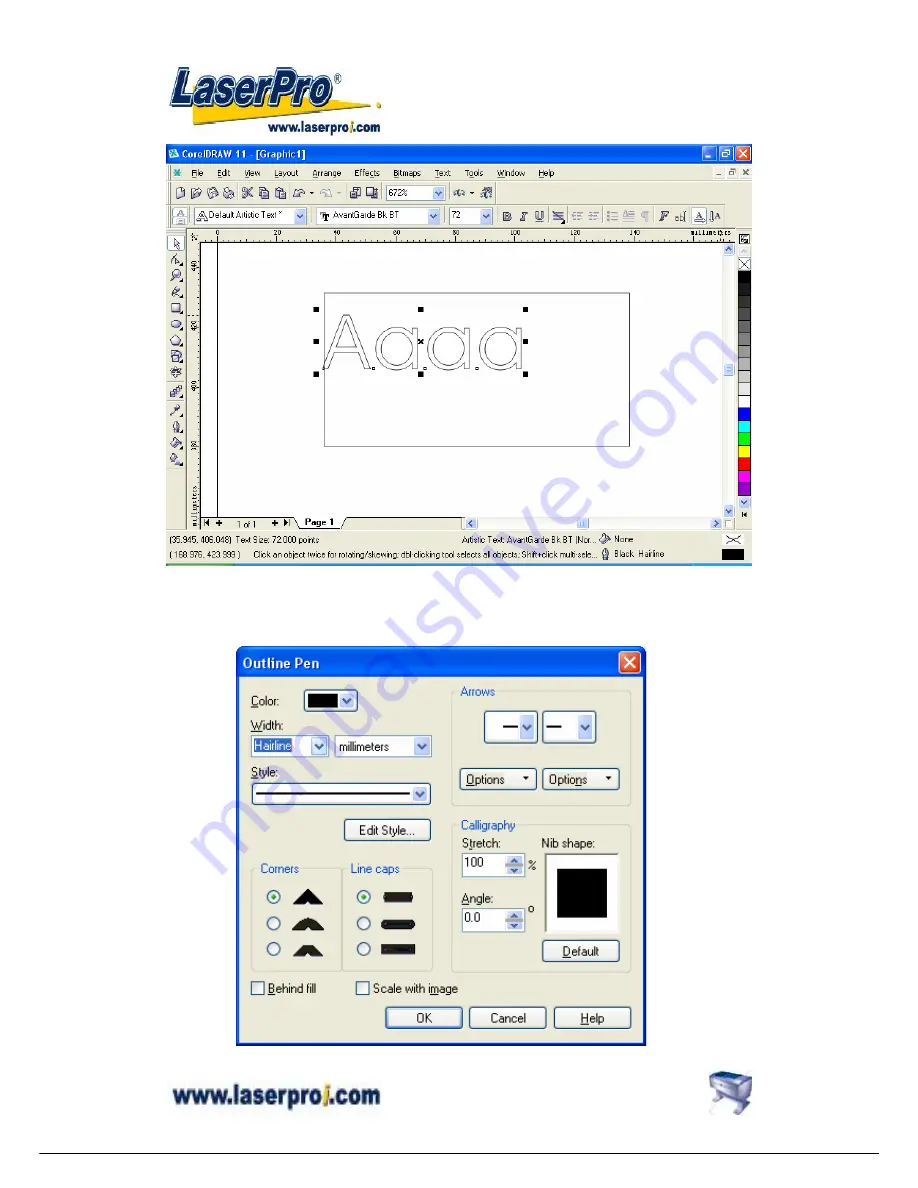

4. Change the outline to its thinnest width by

right clicking

on the selected text

5. Go to the “

Properties”

option

6. Click on the

“Outline”

tab and change the “

Width”

to its thinnest dimension.