This professional quality torque wrench comes with its

own certificate of test and calibration. The shaft of the

wrench is marked up in Newton metres (Nm), pound-foot

(lb.ft), kilogram metre (kg.m) and pound/inch (lb.in).

When selecting a torque wrench, determine what the

average or most common torque setting will be when you

use it. Then choose a torque wrench that will adequately

cover your anticipated torque specifications by selecting

one with an appropriate scale for your requirements.

This torque wrench is ideal for use in noisy environments

as the progressive torque build-up to the selected setting

is easily detected by three clear signals:

• Sight: the mechanism can be seen moving towards

the break point as the load is applied.

• Touch: the operator can feel the torque build-up and

then the very positive click at the break point.

• Sound: audible click at break point.

The handle is free to rotate on the wrench’s shaft so any

twisting of the handle when torqueing up a nut will not

affect the accuracy of the device. Changes to the torque

setting are carried out by pulling a lever-bar from the end

of the handle which is then rotated to obtain the correct

torque setting.

Unlike many other designs of torque wrench, the

mechanism pivots around the square drive and thus

the wrench is not length-dependant; there is no error or

variation to the application of the preset torque value, no

matter where the handle is held.

The drive shank can be pushed through the body of the

wrench which enables the wrench to torque up right-

hand or left-hand threads equally easily.

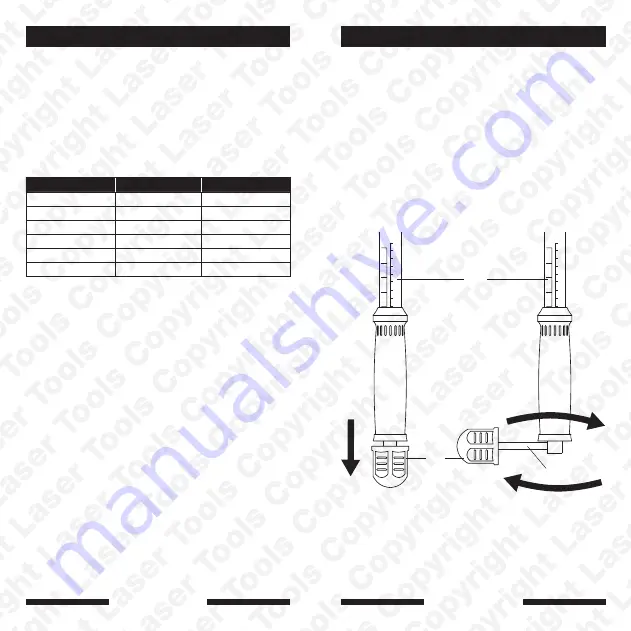

1. Refer to diagram. To adjust torque, first pull the end

cap (

A

) back to release the adjusting lever (

B

).

2. Rotate the adjusting lever clockwise to raise the

desired torque figure and anticlockwise to lower.

Refer to the dual scale (

C

) and adjust to the desired

torque.

3. Lock this figure by pushing the adjusting lever (

B

)

back into the body of the wrench and close the end

cap (

A

).

4. Commence tightening the fixing. You will feel and

hear the wrench mechanism give (or click) when the

set torque is reached. Immediately stop applying

tension to avoid over- tightening.

Instructions

Part Number

Drive

Range

7204

1/4"D

2.5 - 11Nm

7205

3/8"D

5 - 33Nm

7206

3/8"D

12 - 68Nm

7207

3/4"D

140 - 560Nm

7208

3/4"D

200 - 800Nm

7209

1"D

200 - 1000Nm

125

100

75

50

25

60

20

30

40

50

70

80

90

100

Nm lbf-ft

125

100

75

50

25

60

20

30

40

50

70

80

90

100

Nm lbf-ft

1

2

A

B

C

2

3

www.lasertools.co.uk

www.lasertools.co.uk

Our products are designed to be used correctly and with care for the purpose for which they

are intended. No liability is accepted by the Tool Connection for incorrect use of any of our

products, and the Tool Connection cannot be held responsible for any damage to personnel,

property or equipment when using the tools. Incorrect use will also invalidate the warranty.

It is our policy to continually improve our products and thus we reserve the right to alter

specifications and components without prior notice. It is the responsibility of the user to ensure

the suitability of the tools and information prior to their use.

Introduction