OPERATION AND MAINTENANCE

4-13

•

During periods of increasing and or decreasing

temperatures, circuit maintenance maybe

required. The draft compensator circuit will

require maintenance if the pressure is too high or

too low. To maintain the circuit, first adjust the

tractors flow on the circuit being used to

approximately 20%. Then connect the circuit to

the tractor and operate it until the indicated

pressure stabilizes at the desired target setting. If

the pressure rises to 3,000 psi, you are operating

the circuit in reverse and you will need to reverse

the direction of flow and operate the circuit until

the pressure has stabilized at the desired target

setting.

•

Always keep the valve labeled “VALV” turned

OFF when maintaining and operating the draft

comp circuit.

NOTE

The draft comp pressure should always be checked when

the draft comp cylinder is fully extended (mast pin fully

forward). The draft comp pressure will increase as the

large tilt cylinder fully extends, causing the draft comp

cylinder to partially or completely retract.

Typically, the draft compensation circuit will not require

any attention other than a quick glance and note of the

stored pressure once a day.

for those times

your draft compensator circuit needs to be maintained.

These pressures are a good place to start. Never run the

HSL draft compensator at less than 1,100 psi or more

than 2000 psi. You may find that your HSL operates

better at a slightly higher or lower pressure, depending

on your working depth, soil type, soil condition, and other

considerations.

NOTE

The Tilt Controlled HSL is not compatible with the Draft

Compensator System.

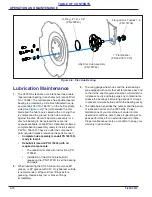

Replacing the Disc Hub

Bearing

1.

The replacement hub and bearing assembly is

available as a pre-assembled assembly, Landoll

185742 for your convenience. Should you choose,

the wear parts are also available in a kit to re-build

the disc hub. Landoll kit 219945 includes the

essential wear parts to rebuild a disc hub in the field.

When rebuilding disc hubs in the field it is highly

recommended that you obtain a die, Landoll 218733,

to assist in the proper assembly of the components in

the hub assembly. Landoll Corporation will not accept

responsibility for, or warranty hub assemblies re-built

in the field.

2.

Clean the O-Ring groove and the surfaces between

the hub face and the correlating disc surface. Failure

to clean the surfaces mentioned above, can cause

the disc blade to loosen and cause water to infiltrate

the bearing area.

3.

Always replace the 1-8 flanged top lock nut, (Landoll

Part No. 174732.)

4.

Use 242 Loctite (Blue) when assembling the spindle

nut

5.

Always torque the flange top lock nut to

approximately 200-250 foot pounds of torque.

NOTE

Inadequate torquing of the disc hub (<120 ft/lb.) flanged

top lock nut will cause premature bearing failure. Over

torquing can also lead to premature bearing failure.

7833 Draft Hydraulic Settings

Model

MAX* Draft Comp Pressure Setting

(When Cylinder Is Fully Extended)

7833-25

1,100 psi.

7833-30

1,300 psi.

7833-35

1,500 psi.

7833-40

1,700 psi.