OPERATION AND MAINTENANCE

4-7

General Operation

1.

The horsepower requirements are typically 8-10

horsepower per foot of cut. This will vary widely due

to speed, depth, moisture, residue and types of soils.

Local dealers can help in making recommendations

for your areas.

2.

Operating speed is typically 4.5 - 6 mph. Excessive

speed can cause the unit to bounce, uneven depth,

and create a ridge on the outside edges. Too low of

speed may not allow the unit to properly fill in the

center furrow.

3.

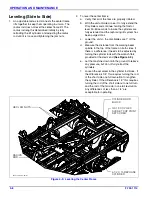

Lift wheels must always be in contact with the ground

and carrying some implement weight. Lift wheels are

used to gauge the depth of each frame section and to

control the leveling feature. Maximum discing depth

cannot be achieved by raising the lift wheels off the

ground. Little or no weight on the lift wheels will

cause the frame sections to gouge, side-draft, and

buckle producing inconsistent cutting depth.

4.

Do not turn with the Disc in the ground, this can put

excessive side load on the gangs and hitch. Raise

the unit slightly when making turns to prevent

gouging and pushing a ridge.

Field Operation

1.

Raise the unit to take the weight off of the transport

locks.

2.

Remove the wing lock pins by sliding forward. Unfold

the wings and extend the fold cylinders completely

noting that the transport locks are also disengaged

CAUTION

Failure to remove wing lock pins before unfolding

wings will cause permanent equipment damage.

Summary of Contents for 6250

Page 2: ......

Page 13: ...STANDARD SPECIFICATIONS 2 5 Table provided for general use NOTES...

Page 21: ...STANDARD SPECIFICATIONS 2 13 Table provided for general use NOTES...

Page 28: ...Page Intentionally Blank...

Page 90: ...NOTES...