Section 1: Assembly & Set-Up

RCFM4014 Rotary Cutter 326-730M

12/11/18

19

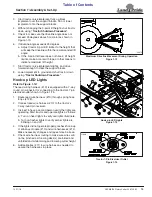

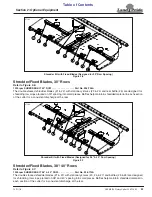

3. Start tractor, raise implement fully up. Back

implement over the support blocks. Do not lower

implement onto the support blocks.

4. Without changing the 3-point lift height, shut tractor

down using

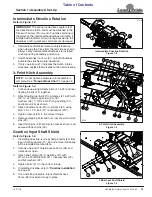

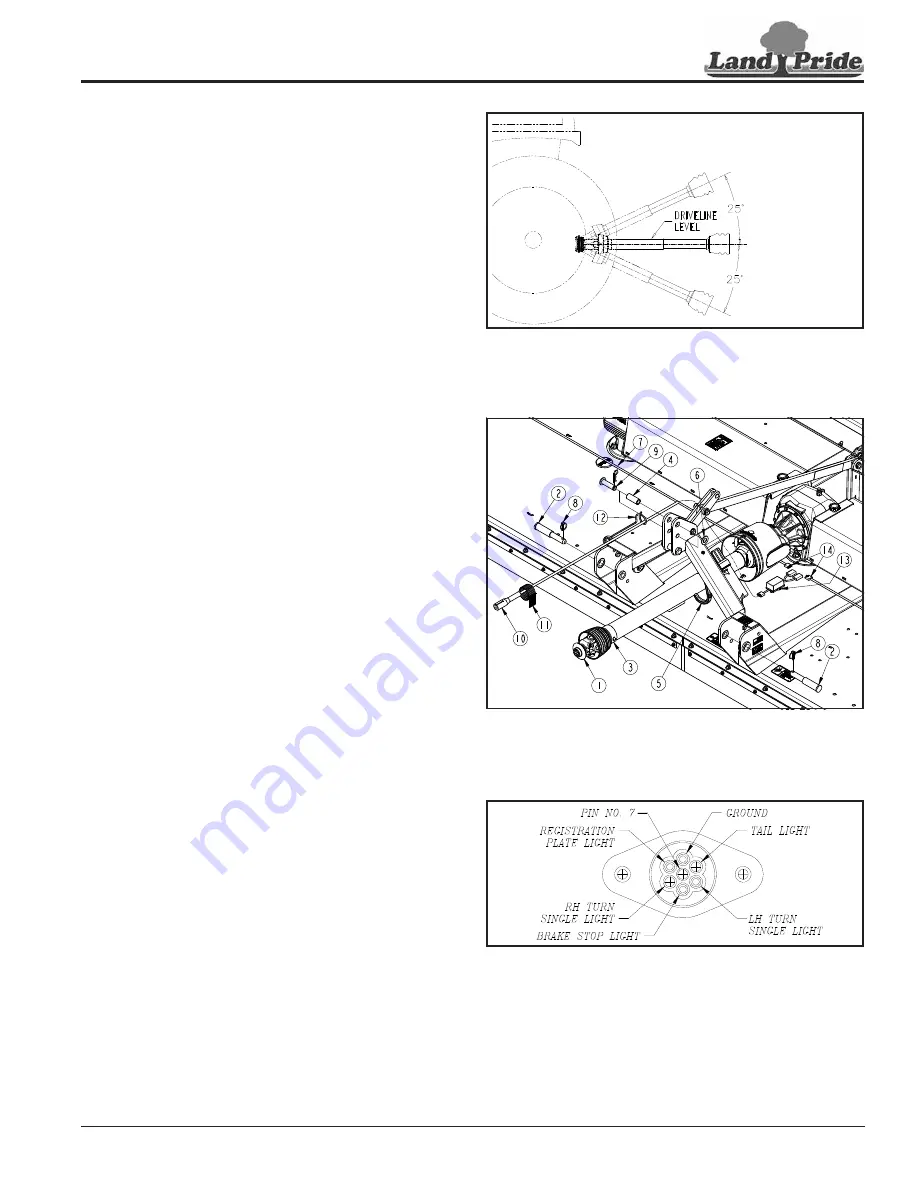

5. Check to make sure the driveline angle does not

exceed 25 degrees above horizontal as shown in

Figure 1-13.

6. If driveline angle exceeds 25 degrees:

a. Adjust tractor 3-point lift limiter to the height that

will keep the driveline within the recommended lift

angle.

b. If the 3-point left lever does not have a lift height

limiter, make a mark with tape or other means to

indicate maximum lift height.

7.

Start tractor, raise implement slightly, and drive

forward enough to clear the support blocks.

8. Lower implement to ground and shut tractor down

using

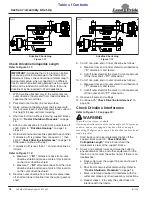

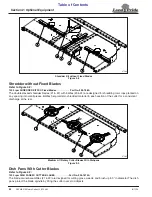

Hook-up LED Lights

The lead wiring harness (#10) is equipped with a 7-way

round pin connector for connecting to the tractor’s 7-pin

electrical outlet shown in Figure 1-15.

1.

Route lead wire harness (#10) through spring hose

loops (#128).

2. Connect lead wire harness (#10) to the tractor’s

7-way round pin receiver.

3. It is best to have a second person verify the lights are

operating. Start tractor and operate lights as follows:

a. Turn on head lights to verify red lights illuminate.

b. Turn on flasher lights to verify amber lights are

blinking on and off.

4. If the lights did not operate properly, recheck hook-up

of enhance module (#13) and wire harnesses (#14).

Make necessary changes and repeat step 3 above.

5. Check wire harness routing to make sure wires will

not be pinched as the wing deck(s) are folded and

unfolded and while raising and lowering cutter height.

6. Add cable ties (#11) to wire harness as needed to

secure the harnesses in place.

Maximum Driveline Movement During Operation

Figure 1-13

Hook-up LED Lights

Figure 1-14

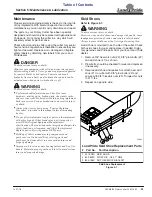

Tractor 7-Pin Electrical Outlet

Figure 1-15

24872

11640