Section 4: Operating Instructions

RCF3096, RCF3010, & RCFM3010 Rotary Cutters 326-566M

11/8/18

49

5. Do not engage power take-off with 3-point cutter fully

raised.

6. Periodically disengage power take-off, shut down

tractor, remove key, and check for foreign objects

wrapped around the blade spindle. Block cutter deck

up before removing objects.

7.

Frequently inspect cutter for loose bolts and nuts.

Tighten all loose bolts and nuts as indicated in the

“Torque Values Chart”

8. For additional information, see

Crossing Steep Ditches & Banks

WARNING

!

To avoid serious injury or death:

Cutting over ditches and backing up hills can tilt the

cutter’s back side up excessively resulting in “

Bottoming

Out

” the driveline. Bottoming out is when the driveline

shaft has shortened to the point it is pressing against the

gearbox and tractor power take-off shafts. Once a

driveline has bottomed out, it can not be shortened

anymore without causing serious damage to the tractor

power take-off components, cutter gearbox and driveline.

Do not operate a pull-type cutter at an angle exceeding

25 degrees up or down or at any angle that will force the

driveline to bind and/or hit the tractor drawbar.

Crossing Steep Ditches and Banks

Figure 4-1

IMPORTANT:

Always cross ditches and banks at a

diagonal. Never cross straight across and never

back into a ditch or bank.

Ditch / Bank

Wrong

Right

Ditch / Bank

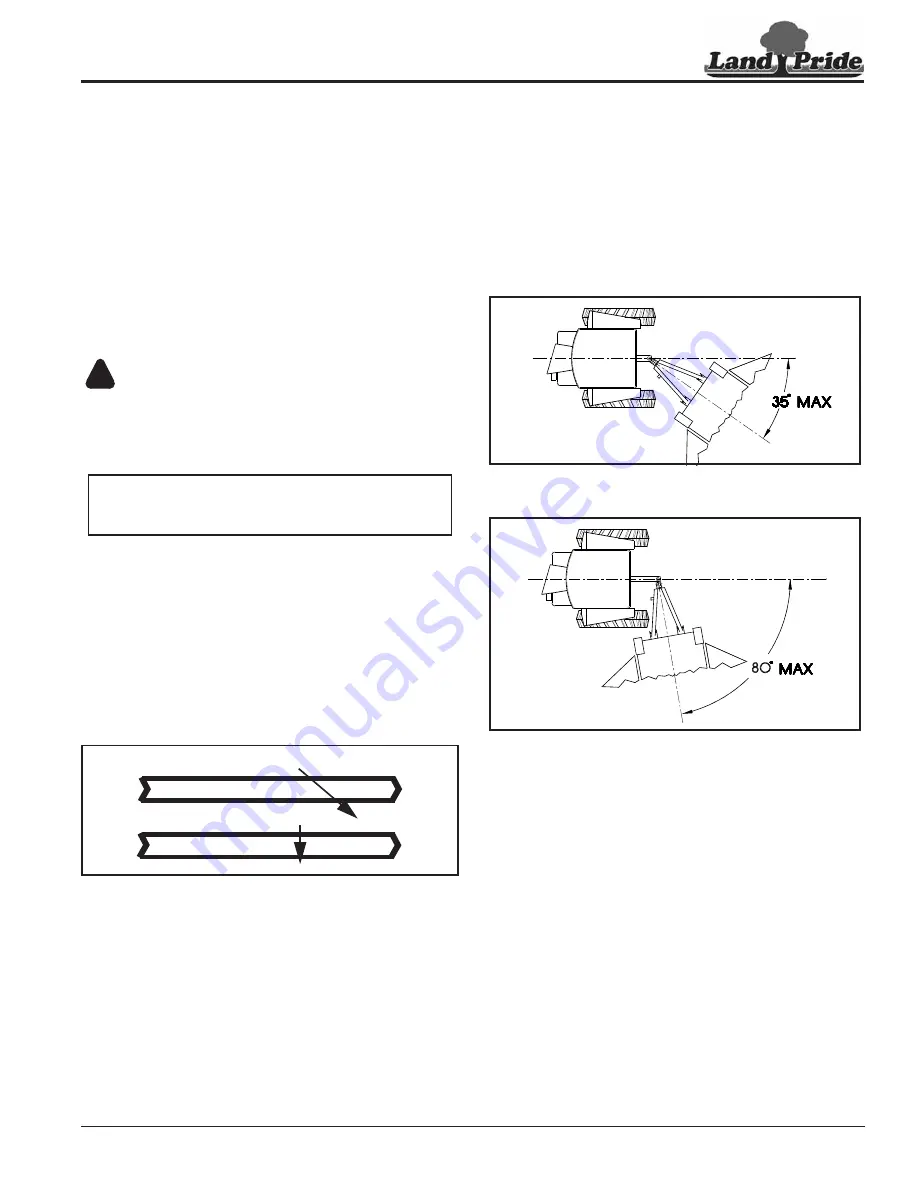

Turning Angles for Pull-Type Cutters

Refer to Figure 4-2 & Figure 4-3:

Avoid tractor-to-cutter turning angles exceeding 35

degrees if main driveline is a standard conventional drive

shaft. The turning angle may be increased to 80 degrees

if equipped with a constant velocity driveline shaft. These

extreme angles are intended for intermittent usage only

and not prolonged usage. Plan your field cutting to

minimize the number of turns as well as extreme angles

where turns are necessary.

Conventional U-Joint Driveline

Figure 4-2

CV Driveline

Figure 4-3

11934

20795