9

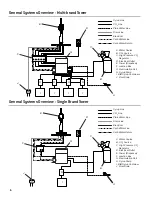

Tower Installation - Multi-brand Tower

Tower Installation - Single Brand Tower

If Unicorn Tower being installed is a Single Brand

Tower with an ADA Panel, skip to next section.

NOTE

1. Place the drip tray into the counter cutout.

2. Route ribbon cable, harness, and syrup/water lines of the

tower through the opening in the drip tray assembly.

3. Guide the tower through the opening in the drip tray and

position the tower facing forward, with the nozzle above the

drip tray.

1.

Plug ADA harness (PN 52-3734) into ADA panel in front of

drip tray.

2. Route all harnesses and syrup/water lines of the tower

through the opening in the drip tray assembly and through

opening in tower collar (PN 05-3491).

3. Place drip tray with collar into counter cutout.

4.

Guide the tower through the opening in the drip tray and

position the tower facing forward, with the nozzle above the

drip tray.

Do not over tighten, this can cause damage to the

ceramic lever.

!

ATTENTION

Do not over tighten, this can cause damage to the

ceramic lever.

!

ATTENTION

A

A

A

A

B

B

B

B

E

D

D

C

C

D

C

C

A. Tower

B. Ribbon Cable, Harness,

Syrup/Water Lines

C. Drip Tray

A. Tower

B. Harnesses & Syrup/

Water Lines

C. Drip Tray

D. ADA Panel

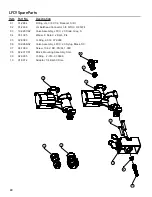

4.

Route ribbon cable, harness, and syrup/water lines through

the the tower connection nut provided, then thread the nut

onto the tower and tighten to secure to counter.

5.

Route tower harnesses and syrup/water lines through the

the tower connection nut provided, then thread the nut onto

the tower and tighten to secure to counter.

A. Tower

B. Connection Lines

C. Counter

D. Connection Nut

A. Tower

B. Connection Lines

C. Counter

D. Connection Nut

E. Tower Collar

(Under Drip Tray)

5. Connect drain line to drain fitting at drip train and route to

open type drain.

6.

Connect drain line to drain fitting at drip tray and route to

open type drain.

Summary of Contents for 85-3151R-20-11111-22

Page 27: ...27 Wiring Diagram LFCV...

Page 28: ...28 Wiring Diagram VV...

Page 29: ...29 Counter Cutout Not to Scale...