PAGE 6

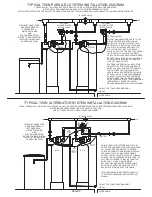

(All electrical & plumbing should be done in accordance to all local codes)

1. LOCATION: Place the softener where you want to install it, making sure it is on a clean, level and firm surface. The

plug-in power adaptor is for dry locations only. Use an uninterrupted electrical outlet installed within 15 feet of the softener.

Locate the softener so the distance between the drain and the softener is as short as possible. Brine tank should be easily

accessible. Do not install the softener with less than 10 feet of piping between its outlet and the inlet of a water heater.

Do not locate the softener where it or its connections (including the drain and overflow lines) will ever be subject to room

temperatures under 40°F.

2.

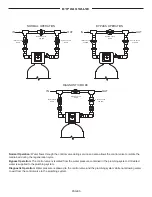

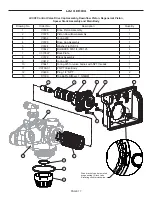

INLET/OUTLET: Connect to a supply line downstream of outdoor spigots. Install an inlet shutoff valve and plumb to the

un

it’s inlet located at the left front as you face the unit. Installation of a bypass valve is recommended. If using plastic fittings

ground the water conditioner per local electric codes. If a water meter is used, install the water meter on the outlet side of

the control valve. It is recommended that the meter assembly be installed horizontally or in a downflow vertical position

to reduce turbine bearing wear. The turbine assembly may be oriented in any direction, but is usually oriented pointing up

to reduce drainage out of the pipes during service. Remove the cover and drive bracket and thread the water meter cord

through the hole in the back plate. Reinstall the drive bracket. Weave the cord through the hooks on the right hand side of

the drive bracket and connect the end to the three prong connector labeled METER on the printed circuit board. Replace

the cover.

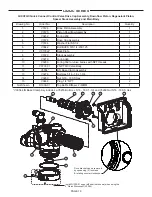

3. A jumper ground wire should be installed between the inlet and outlet pipe whenever the metallic continuity of a

water distribution piping system is interrupted. Install grounding strap on metal pipes.

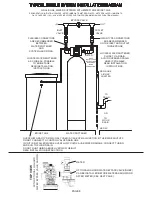

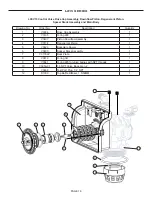

4. DRAIN: The drain must be able to handle the backwash rate of the softener. Correctly size the drain line for the softeners

drain line flow control gpm rating. An adapter fitting is supplied with the valve that can connect a 3/4” fitting to be used with

drain line flow controls up to 10 gpm, a 1” fitting to be used with drain line flow controls up to 25 gpm, or a 1-1/2” fitting to be

used with drain line flow controls up to 50 gpm. If soldering, joints near the drain must be done prior to connecting the drain

line flow control fitting. Leave at least 6” between the drain line control fitting and solder joints when soldering pipes that are

connected on the drain line control fitting. Failure to do this could cause interior damage to the drain line flow control fitting.

Avoid elevating the drain line above the control valve where possible.

Never insert a drain line directly into a drain, sewer

line, or trap. Always allow an air gap between the drain line and the wastewater receptacle to prevent the possibility

of sewage being back-siphoned into the softener.

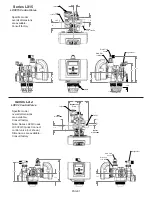

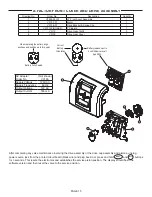

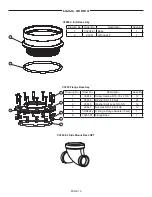

5. REGENERATION: The brine refill flow control assembly is installed in an easy to access refill elbow located on the control

valve. The LX15 series refill flow control assembly is attached to the 1.5” control valve with a locking clip. The locking clip

allows the elbow to rotate 270 degrees so the outlet can be oriented towards the brine tank. The LX2 and LX2QC series

refill flow control assembly is attached to the 2” control valve with a V3151 nut. Connect the brine line polytubing found with

the brine tank to the brine connection on the control valve. The 1.5” control valve has a standard refill elbow to which a 1/2”

flexible tube can be connected, see

below. One polytube insert is shipped on the brine line elbow’s locking clip. Remove

this white polytube insert and replace the locking clip. The second polytube insert is taped to the top of the brine well cap in

the brine tank. Press the polytube inserts into each end of the provided brine tubing, press the polytube with insert into the

nut on the brine fitting. Tighten nut securely to create a pressure tight connection. The nut, gripper and retainer sleeve is a

three-piece assembly that can come apart from the elbow body. Parts must be reassembled exactly as shown to function

properly. If the nut is completely removed from the body, slip the nut, plastic gripper and retainer sleeve on to the tube then

tighten on to the fitting.

Note that 1/2” O. D. brine tube runs longer than 6 feet may restrict draw rates for LX15 series softeners using 21” or

larger diameter mineral tanks. Locate brine tank as close as possible to softener. Increase brine tubing size to 5/8”

O. D. if necessary.

Make sure the floor is clean beneath the brine tank and that it is level and smooth. Install brine tubing

to the brine tank using the above instructions.

The LX2 and LX2QC Series 2” control valves have a 1” PVC refill elbow

connection (fitting kits available for 1/2” and 5/8” O. D. tubing connections); use 1” pipe to connect brine tank to

2” control valves for 30” or larger diameter mineral tanks.

6. OVERFLOW: A 1/2” (inside diameter, not provided) gravity drain line should be connected to the overflow fitting on

the side of the brine tank. This overflow is in case of a malfunction in the brine shut off. If the unit is installed where water

may flow in the event of an overflow and cause water damage, connect a length of flexible tubing and run to a drain below

the level of the overflow.

(Do not connect the tubing to the drain line on the control valve. Do not run tubing above

overflow height at any point. Provide air gap.)

INSTALLATION INSTRUCTIONS

BRINE LINE FITTING CONNECTIONS

DRAIN LINE FITTING CONNECTION USING 5/8" POLY TUBE

Click to buy NOW!

PD

F-XCHANGE

w

ww

.docu-track.c

om

Click to buy NOW!

PD

F-XCHANGE

w

ww

.docu-track.c

om

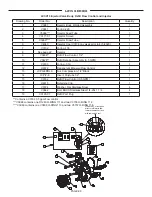

Summary of Contents for LX15 Series

Page 34: ...PAGE 34 NOTES ...

Page 35: ...PAGE 35 ...