Maintenance

Cleaning of

Roll

er

s

The

Leon13DX

comprises six roll

er

assemblies. They should be periodically cleaned to

ensure

proper performance

and high quality

lamination. The cleaning intervals should be

determined based on the operating demand of the equipment.

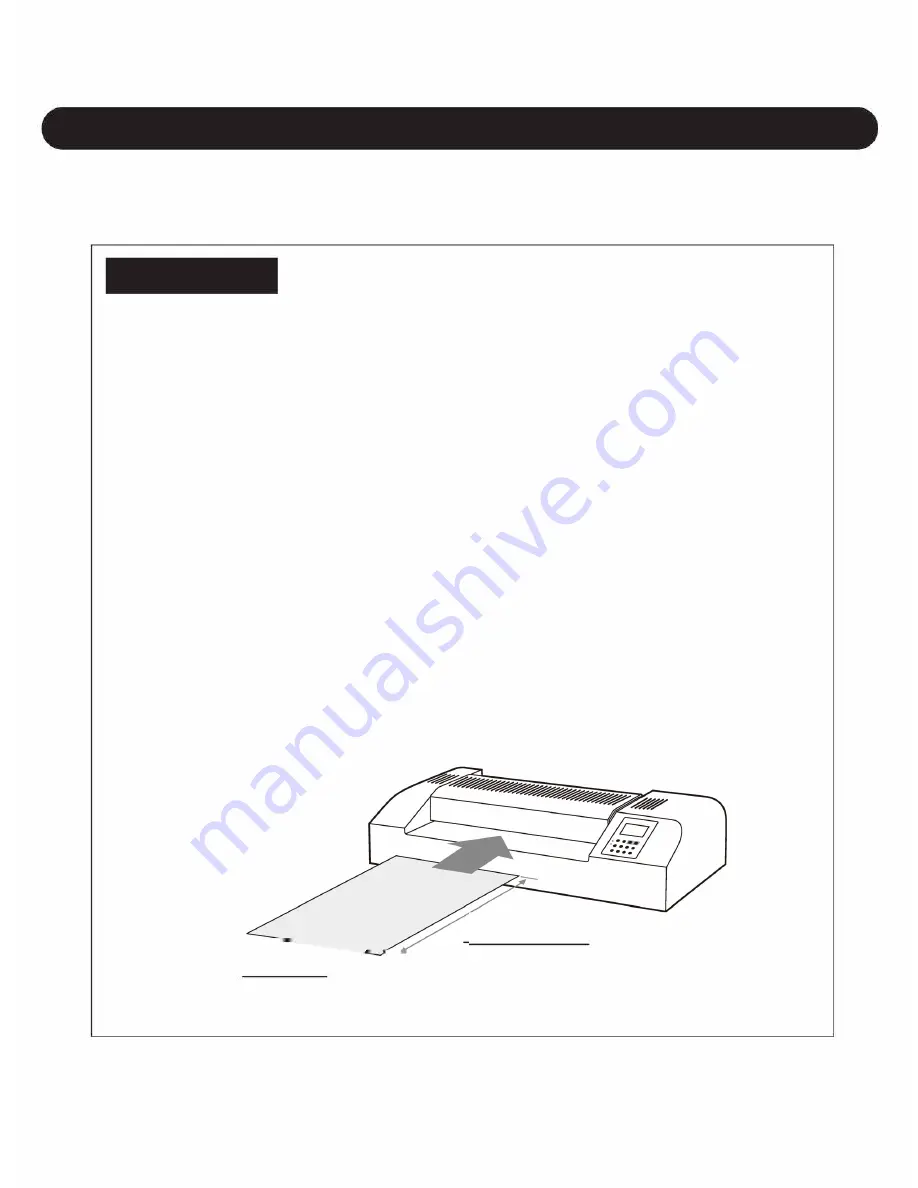

Cleaning method

Prepare a thick paper e.g. drawing paper (note: some of the pack type laminate films

manufactured

contain cleaning papers applicable for this purpose).

The paper should have a size of 12" x 12" to 20", and the thickness should be 60 to 80 lb.

Set the laminate temperature to 212 to 248

o

F.

When the temperature rises to the specified value, set the speed to [1] or [2].

Insert the paper into the equipment through the laminate

film

/material inlet.

Stains, including adhesive residues, left sticking to the surface of the roll

er

s will be

transferred

to the paper.

Repeat the above steps two or three times.

To ensure higher cleaning effectiveness, cleaning should be performed at intervals

of every 100 to 200 laminate films processed.

*

Stained papers or paper thicker than 1/8" should not be used. The equipment may be

damaged.

*

No liquid cleaners/detergents or abrasive cleaners are acceptable for cleaning the roll

er

s or

unit main body which could result in permanent damage to the equipment.

Temperature Setting:

Speed Setting:

212

o

F

[1] or

[2]

��� -

Approx. 12"

1/

Up to approx. 20"

15

Thick Paper

Leon13DX

Summary of Contents for Leon13DX

Page 1: ...Leon13DX User Manual ...

Page 20: ......