INSTRUCTIONS FOR THE INSTALLER

8

2.

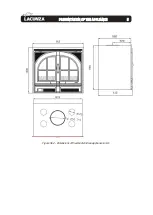

Key to casing diagram:

1 Ceiling

2 Flue

3 Incombustible material (Inner hood

insulation)

4 Insulating deflector made of

incombustible material

5 Wall

6 Fresh-air inlet (1,000 cm

2

)

7 Hot-air outlet (1,000 cm

2

)

Figure No.5 -

Exterior diagram of the casing

In order to enable suitable air

circulation and correct operation, the

casing must have a fresh-air inlet with a

minimum section of 1,000cm

2

beneath the

level of the actual appliance and a hot-air

outlet measuring at least 1,000cm

2

above

it (just before the insulating deflector

inside the casing). These inlet and outlet

sections must ensure air renewal in such a

way as to avoid damage to parts inside the

hood due to excess temperature.

A further hot-air ventilation grille is

also recommended between the insulating

deflector on the hood and the ceiling.

On non-central-heating appliances

(without back boiler), Lacunza does not

recommend enveloping the outside of

appliances with insulation.

The installer must fit the necessary

inspection accesses (trap doors, hatches,

etc.) so that everything inside the hood

that may need maintenance work or

replacement can be accessed at any time,

e.g. counterweight system, hydraulic

components, heating circuit safety

components.

2.3.6.

Connection to the flue

The appliance must be connected to

the chimney flue using special piping

designed to resist the products of

combustion

(e.g.

stainless

steel,

enamelled steel, etc.).

To connect the flue to the socket

flange, insert the piping inside the flange

and seal the joint with fire sealant or fire

cement to make it completely airtight.

The installer must ensure that the pipe

connected to the appliance is well secured

and there is no chance of it coming free

from its housing (e.g. as a result of

dilatation due to temperature, etc.).

2.3.7.

Piping air to other rooms (Andrea

/ Abodi)

It is possible to pipe some of the heat

generated to other rooms in the house

using the appliance. This does not mean

that the appliance works more efficiently,

but it does mean that the heat it creates is

distributed better. For this purpose, in the

top surface of the appliance there are 2

potential hot-air outlets with diameters of

120mm on the top shell of the appliance.

Pipes can be fitted from these outlets to

other rooms. If you intend to do this, bear

the following points in mind.

Do not break the scored steel

circles completely. Simply bend them in

order to facilitate the conduction of

heat to the pipe.

Summary of Contents for Sara

Page 1: ...Sara Lorea Abodi Andrea Instruction Book...

Page 6: ...PRESENTATION OF THE APPLIANCE 5 1 Figure No 2 Dimensions of the Abodi Andrea appliance in mm...

Page 19: ...BASIC BREAKDOWNS 18 6 BASIC BREAKDOWNS 6 NO TRADUCIR EL TEXTO DE ESTA IMAGEN...

Page 21: ...DECLARATION OF PERFORMANCE 20 7 DECLARATION OF PERFORMANCE 7...

Page 22: ...DECLARATION OF PERFORMANCE 21 7...

Page 23: ...DECLARATION OF PERFORMANCE 22 7...

Page 24: ...DECLARATION OF PERFORMANCE 23 7...

Page 25: ...CE MARK 24 8 CE MARK 8...

Page 26: ......