User’s Manual - Mascot II Boilers and Water Heaters

Page 3

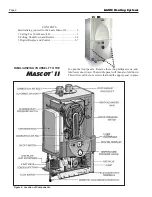

1. Caring For Your Mascot II

Your Mascot II will require very little

maintenance. However, as with any fine appliance

there are certain steps that should be taken to ensure

continuing optimum performance.

1.1 General Care

Keep the area around the Mascot II clean and

free from combustible materials, gasoline and other

flammable liquids and vapors.

The Mascot II must be completely isolated and

protected from any source of corrosive chemical fumes

such as trichlorethylene, perchlorethylene, chlorine,

etc.

Keep bottom and top openings on the boiler free

for proper ventilation of interior components.

Do not obstruct or block a free flow of air to the

boiler to ensure proper ventilation.

If desired, clean the jacket surfaces with a damp

cloth and mild detergent. Do not use flammable

cleaning materials.

If sidewall vented, keep the vent terminal clear

of obstructions — do not pile snow against the vent

terminal. Clean the intake screen often, and then

develop an appropriate maintenance schedule.

1.2 Annual Inspection of Flue and Vents

Visually inspect the vent pipe once a year. Should

any deterioration exist, have the affected parts replaced

by a qualified service person.

1.3 In the Event of a Power Failure

The Mascot II can not be operated during

an electrical power outage. If there is an extended

power outage with danger from freezing, then the

Mascot II (and all other water systems) should be

drained completely. When draining the boiler, turn

off main electrical disconnect switch. When placing

back in service, refer to Section 2 of this Manual for

instruction. All draining and filling must only be done

by a qualified service person.

1.4 Full Service Every Three (3) Years

In addition to the annual visual inspections, a

qualified service agency should conduct a detailed

inspection of all flue product carrying areas of the

boiler and its venting system.

2. Filling, Shut Down and Restart

2.1 Filling the Boiler System

1. Ensure the system is fully connected. Close all

bleeding devices and open make-up water valve.

Allow system to fill slowly.

2. Move manual lever on 3-way valve actuator to

“open” position, allowing air to purge from boiler

loop. Valve is normally in DHW position until

there is a call for Central Heat via “T-T” contacts.

3. If a water pressure regulator is provided on the

make-up water line, adjust the pressure regulator

to provide at least 12 psi (81.8 kPa) at the highest

point in the heating loop.

4. Open bleeding devices on all radiation units at the

high points in the piping throughout the system,

unless automatic air bleeders are provided at such

points.

Note that there is an air bleed located on the left

side of Mascot II, on top of the jacket.

5. Cycle the boiler pump on and off 10 times, 10

seconds on and 10 seconds off to remove all air

from the heat exchanger. Then run system and

appliance pump for a minimum of 30 minutes with

the gas shut off.

6. Using manual lever located on left side of 3-way

valve actuator, move from “open” position back to

closed position repeatedly. This process forces air

out of the internal DHW loop.

WARNING

Failure to remove all air from the heat exchanger could

lead to property damage, severe injury or death.

7. Recheck all air bleeders as described in Step 4.

8. Shut down the entire system and vent all radiation

units and high points in the system piping, as

described in Step 4.

9. Close make-up water valve and check strainer in

pressure reducing valve for sediment or debris from

the make-up water line. Reopen make-up water

valve.

10. Check gauge for correct water pressure and then

the system is ready for operation.

11. Refer to local codes and the make-up water valve

manufacturer’s instructions as to whether the

make-up water valve should be left open or closed.

12. After placing the unit in operation, the ignition

system safety shutoff device must be tested.