LAARS Heating Systems

Page 2

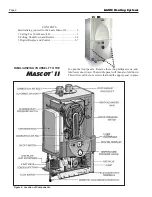

Figure 2. Location of Components.

CONTENTS

Familiarizing yourself to the Laars Mascot II ................2

1. Caring For Your Mascott II ........................................3

2. Filling, Shut Down and Restart ...............................3-4

3. Digital Display and Control ....................................5-7

To open the front panels. Remove these two phillips screws, and

fold lower door down. The middle panel will then also fold down.

This will reveal the four screws that hold the upper panel in place.

M

ASCOT

®

II

FAMILIARIZING YOURSELF TO THE