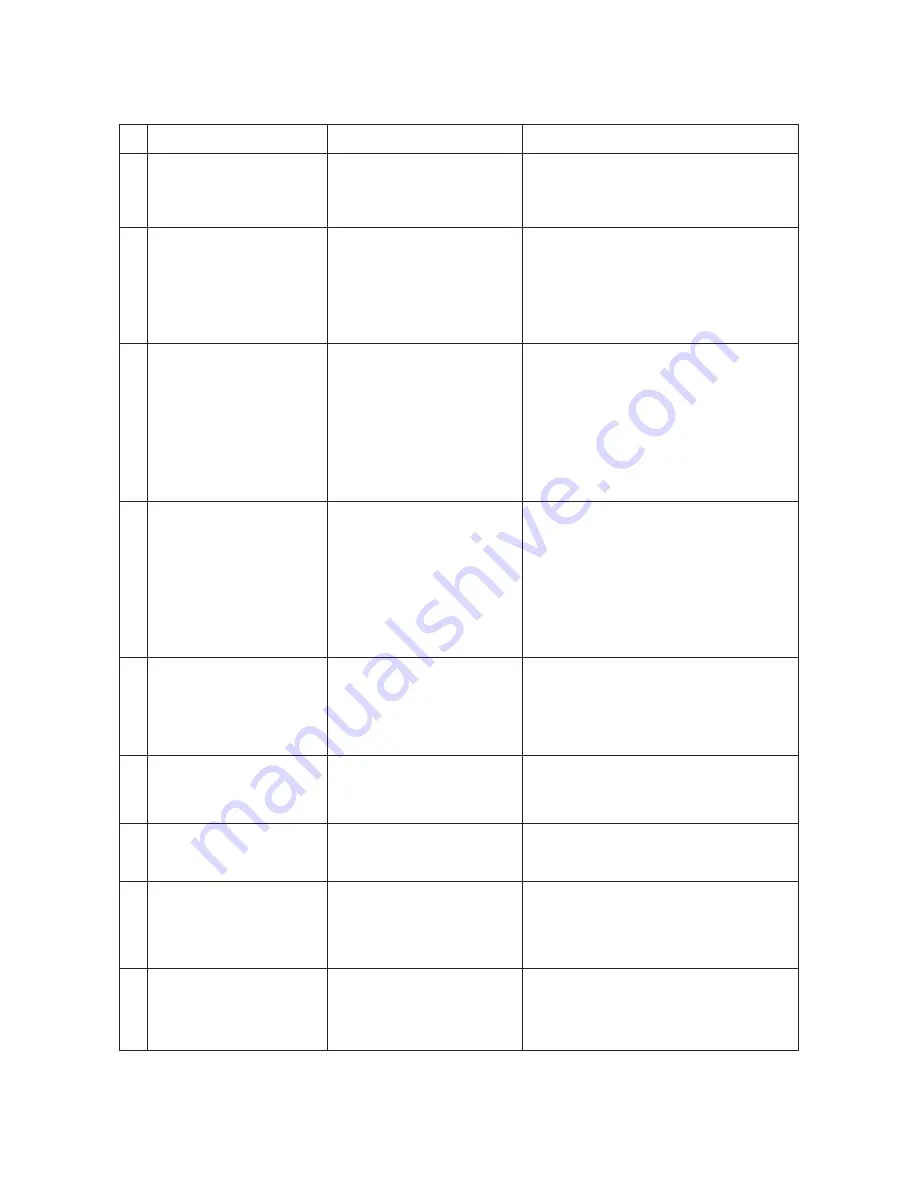

33

11. Problem solving

PROBLEM

CAUSE

SOLUTION

1. The boiler is full of water and

the water flows out of the

safety valve.

• One of the outfl ow lines from the

boiler or from a circuit of the unit

has a leak.

• Check the autolevel circuit, the manual charging

button, and the boiler heat exchangers.

• Replace worn or damaged parts to eliminate

the leak.

2. The safety valve trips in

and vents the steam.

• Malfunction of electrical system

(the electrical heating element

is always connected).

• Pressure increase in the boiler

(the safety valve trips in at 1.9-

2.5 bar).

• Check the wiring that feeds the heat-ing ele-

ment and the pressure switch.

• In the machines with electronic tem perature

control, check the proper operation of the elec-

tronic control unit, the triac, the level probe, and

the elettrical wiring.

3. The machine was started prop-

erly but the water in the boiler

does not warm up.

• The electric heating element is

defective or is not connected.

• Check if the heating element is con-nected to

the power supply.

• Check if the heating element safety thermostat

has tripped in and check its proper operation.

• In the machines with electronic tem perature

control, check the proper operation of the elec-

tronic control unit, the triac, the level probe, and

the elettrical wiring

4. There is no water fl owing from

a serving unit.

• Coffee ground too fine or ex-

cessive quantity for type of fi lter

used.

• Clogged water circuit.

• Defective solenoid.

• Adjust the grinding coarseness and/or the quan-

tity of ground coffee.

• Check that the injector, the upper cir culation

tube, the spray nozzle and the solenoid of the

unit are not clogged.

• In the machines with electronic metering, check

the displacement meter and its valves.

• Check the solenoid of the unit, its wiring and

the fuse in the electronic control unit.

5. The programmed servings of

espresso coffee are not con-

stant or vary on the dif- ferent

units.

• Abnormal operation of the elec-

tronic control unit or of the dis-

placement counters.

• Leak from serving unit solenoid

valve.

• Program the serving quantities sepa rately on

each serving unit. If the problem persists, re-

place the dis placement meter of the serving

unit affected.

• Replace the solenoid valve of the serving

unit.

6. It is not possible to pro- gram

the serving quantities on unit 1

and to copy them on the other

units.

• Abnormal operation or defective

displacement meter of unit 1.

• Check the control unit-displacement meters

electrical wiring.

• Replace the displacement meter.

7. Displacement meters alarm.

• Displacement meters jammed

or defective.

• Defective wiring.

• Replace the displacement meter.

• Check the wiring and its connections, the con-

trol unit and the fuses.

8. Autolevel alarm.

• Lack of water in the autolevel

circuit.

• M a i n w a t e r s u p p l y v a l v e

closed.

• Faulty autolevel solenoid.

• Check the hydraulic circuit of the autolevel.

• Check if the on-off valve on the water supply

is open.

• Replace the autolevel solenoid.

9. The machine is switched on

(the main switch is in position

1 or 2 and the signal light is lit)

but the electronic control is out

of order.

• The electric wiring of the elec-

tronic control unit is defective.

• The electronic control unit is

defective.

• Check the electrical wiring, the elec tronic con-

trol unit and its components.

• Replace the electronic control unit.