Rigging procedures

Rigging procedures

Tools

Before rigging this product, make sure all the tools listed are available. References are given for FACOM

®

products in this

table. Other manufacturers can be used.

name

reference

distributor

set of 6-point 1/4" sockets

RL.NANO1 / R.360NANO

FACOM

torque screwdriver (2 - 10 N.m)

A.404

FACOM

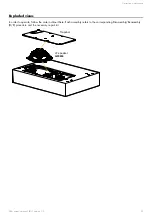

Wall- or ceiling-mounting SB6i with SB6i-onCW

wall-mounting

type of deployment

ceiling-mounting

rigging accessories

SB6i-onCW, including:

• surface-mounting plates

• 4 M6×35 Torx screws

• 4 silent blocks

• 4 spacers

• 8 washers

additional material

4 compatible screws and anchors

torque screwdriver

T30 Torx bit

tools

T20 Torx bit

min. number of operators

1

Fasteners for wall-mounting or ceiling-mounting

Secure the rigging element with four round or pan head M6 screws.

Select screw length and anchors applicable to the wall or ceiling properties.

SB6i owner's manual (EN) version 1.0

21

Summary of Contents for SB6i

Page 1: ...SB6i owner s manual EN ...