Rigging procedures

Assembly

Procedure

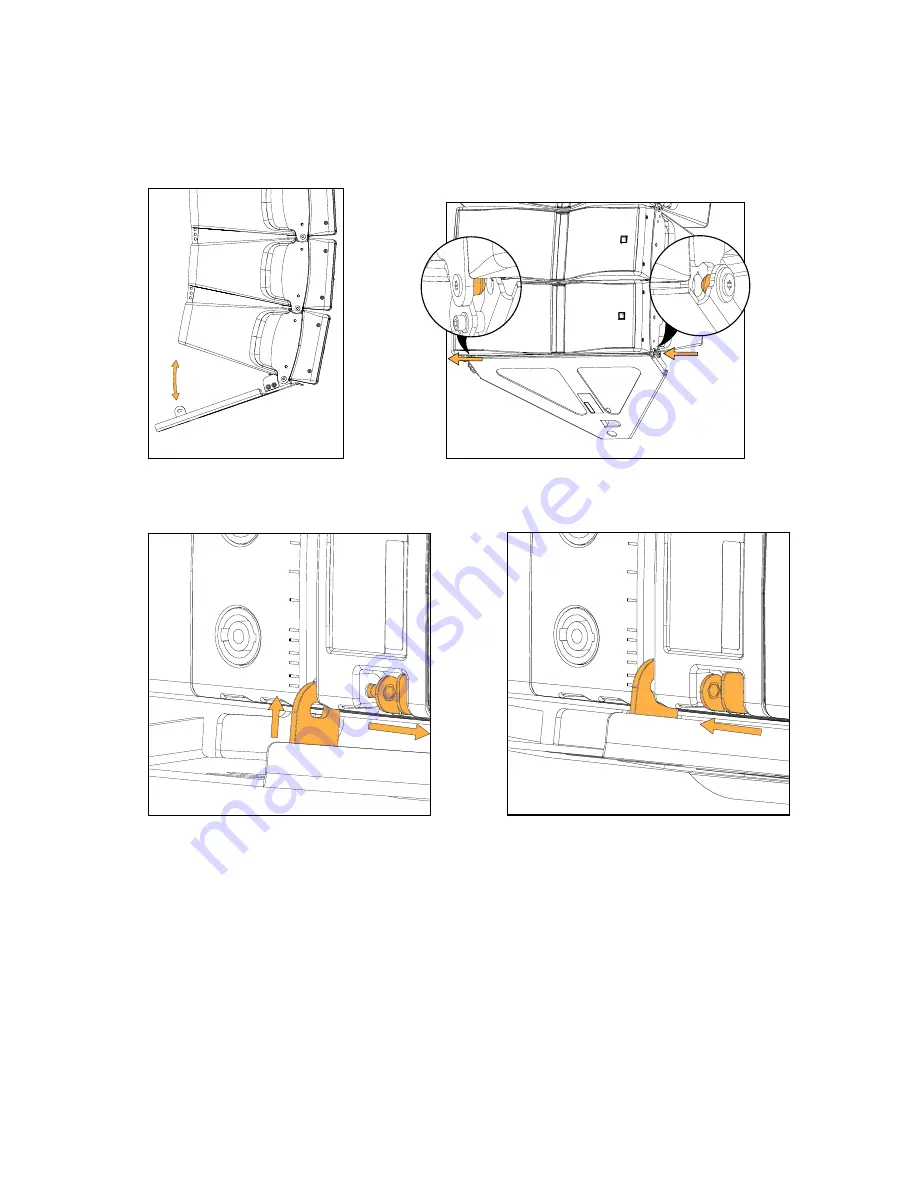

1.

Secure a KIVA-PULLBACK under the bottom enclosure.

Rotate the accessory to nd the correct locking position.

Secure the rear piece in the spring-lock safety of the bottom enclosure.

SHLAK !

31

Kiva II rigging manual (EN) version 2.0