2LW/2LX-2

2-4-16

Adjusting the scanning position for originals from the DP (alternative command for the maintenance

mode U068)

Description

Adjusts the position for scanning originals from the DP. Performs the test copy at the four scanning positions

after adjusting.

Purpose

Used when the image fogging occurs because the scanning position is not proper when the DP is used. Exe-

cute KCFG “EESS”,4, 107, 1, “#1”; command to adjust the timing of DP leading edge when the scanning posi-

tion is changed.

Example: DP READ set to 15, BLACK LINE set to 3

!R! KCFG “SCAN”,9,1,15; KCFG “SCAN”,9,2,3;EXIT;

Format

!R! KCFG “SCAN”,9, #1,#2;EXIT;

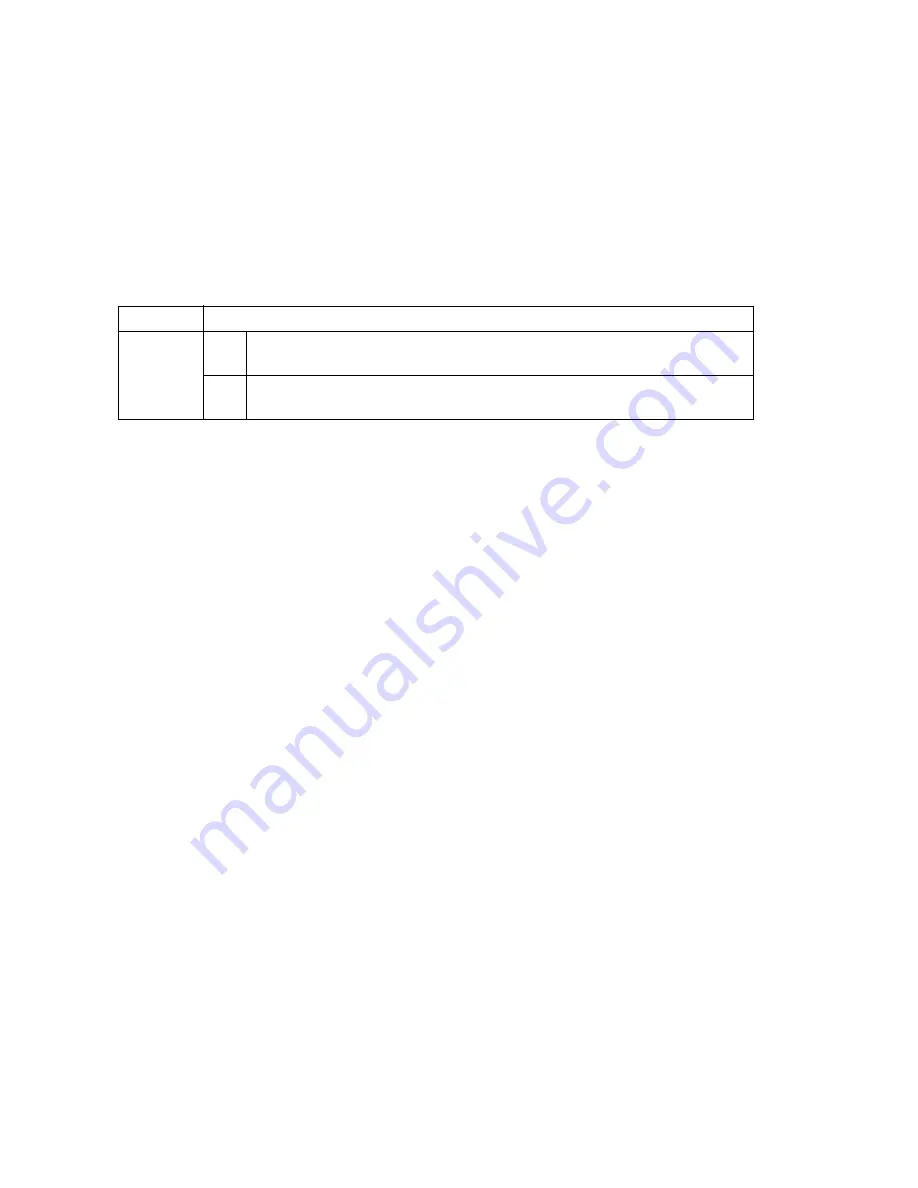

Parameter

#1

1: DP READ Starting position adjustment for scanning originals

2: BLACK LINE Scanning position for the test copy originals

#2

#1=1: Adjustable range: -33 to 33 (in 0.086mm increment) (0: default)

#1=2: Adjustable range: 0 to 3 (in 0.22mm increment) (0: default)

Summary of Contents for ECOSYS FS-3140MFP

Page 1: ...SERVICE MANUAL Published in May 2013 842LX117 2LXSM067 Rev 7 FS 3040MFP FS 3140MFP ...

Page 4: ...This page is intentionally left blank ...

Page 10: ...This page is intentionally left blank ...

Page 104: ...2LW 2LX 1 3 76 This page is intentionally left blank ...

Page 219: ...2LW 2LX 2 1 24 This page is intentionally left blank ...

Page 227: ...2LW 2LX 2 2 8 This page is intentionally left blank ...

Page 251: ...2LW 2LX 2 3 24 This page is intentionally left blank ...

Page 271: ...2LW 2LX 2 4 20 This page is intentionally left blank ...