Section 2.0 - Set Up & Start Up

Work Safely. Always wear safety glasses near the machine.

After the connections are complete, begin the following:

1.

Turn the machine on (twist E-Stop). The 4 line LCD display will show a “welcome” screen in about 20-25

seconds. This lasts only 3 seconds. The main menu will appear in about 25-30 seconds after power-up.

(Main Menu is: “RUN JOB” screen)

2.

Be sure the tooling / fixturing is secure on the KwikMark base prior to attempting any marking operation.

3.

Using the Arrows on the Key Board, jog the tip to the desired position over the surface you wish to mark.

4.

Adjust the air pressure (PSI) with the regulator on the side of the machine. Turn the handwheel on top of the

KwikMark until the tip is the approximate distance. Per chart below.

Machine Start Up

The above are only approximations. It is more important to tune the frequency of the pin for a nice BZZZZZZZZ

sound. If the pin is too far away it will be a low pitch, too close and the pin will stall and scratch not impact material.

The KwikMark has two modes of operation:

Express Text:

• Single Line

• Normal Text

• Marks from Current Pin position

• Does not Save File

For Express Text: Press F1 on the (ps-2) keyboard. Follow LCD screen prompts as follows:

• Type the text you wish to mark (press Enter)

• Accept default text height or type over (press Enter)

• Press Space Bar to begin marking cycle

Or

Standard Text:

• Limitless Amount of Lines / File

• Straight, Angular or Arc Text

• Infinite Font Size / Line

• Each Line has X-Y Position

• Multiple Serial Numbering / File

• Date Code & Time Stamping

• Graphics Marking

• Saves the File

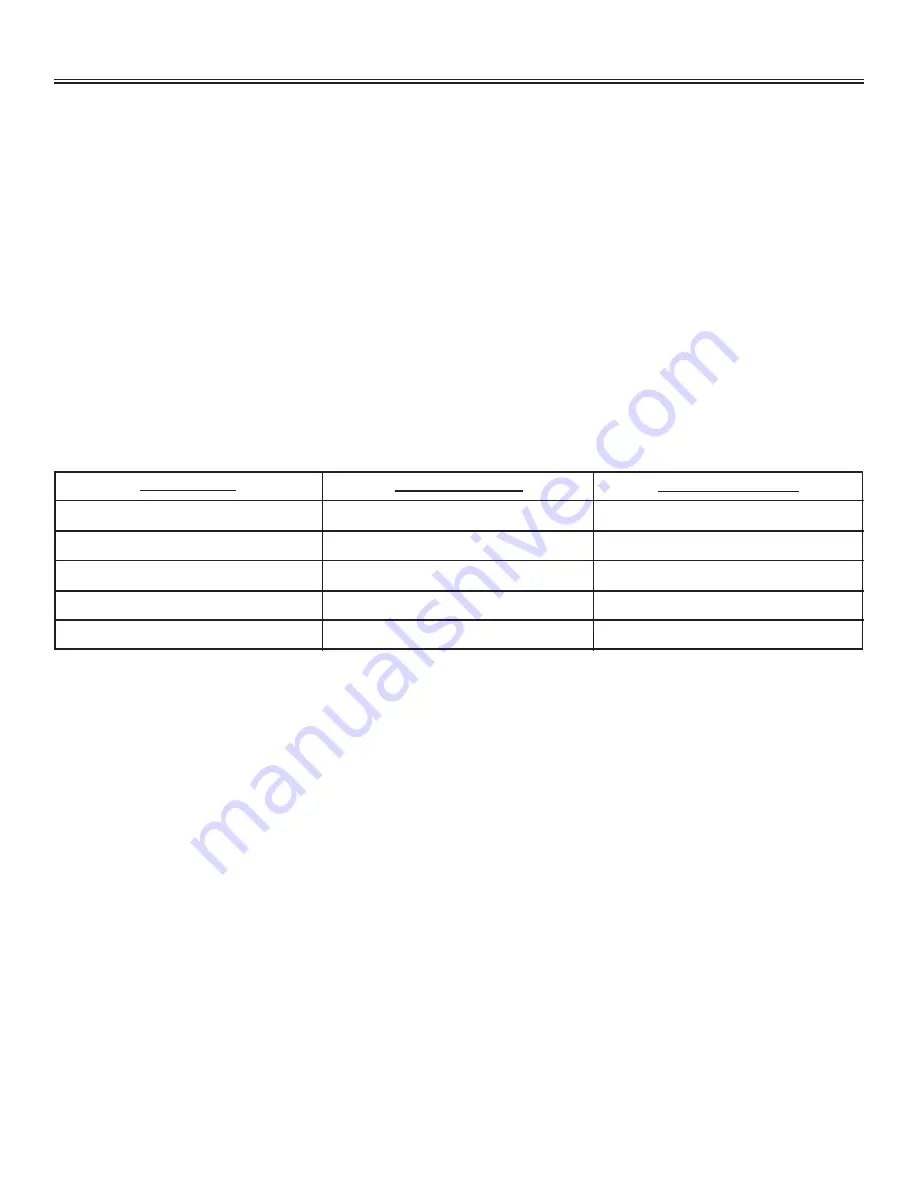

Marking Type

Ultra Fine

Fine - Medium

Medium

Medium - Heavy

Heavy - Deep

Air Pressure (PSI)

15 - 25

25 - 35

35 - 45

45 - 65

65 - 85

Distance Tip to Part

.050

.100

.125

.160

.200 +

Summary of Contents for KM-64

Page 4: ...SECTION 1 0 GENERAL DESCRIPTION ...

Page 6: ...SECTION 2 0 SET UP START UP ...

Page 9: ...SECTION 3 0 QUICK REFERENCE GUIDE ...

Page 20: ...SECTION 4 0 RULES ...

Page 25: ...SECTION 5 0 CONTROLS ...

Page 30: ...SECTION 6 0 MACHINE DIAGRAMS ...

Page 31: ...Section 6 0 Machine Diagrams Work Safely Always wear safety glasses near the machine ...

Page 32: ...Section 6 0 Machine Diagrams Work Safely Always wear safety glasses near the machine ...

Page 33: ...Section 6 0 Machine Diagrams Work Safely Always wear safety glasses near the machine ...

Page 34: ...Section 6 0 Machine Diagrams Work Safely Always wear safety glasses near the machine ...

Page 36: ...SECTION 7 0 MAINTENANCE ...

Page 39: ...Section 7 0 Maintenance Work Safely Always wear safety glasses near the machine ...

Page 40: ...SECTION 8 0 POWER REQUIREMENTS ...

Page 42: ...SECTION 9 0 ELECTRICAL SCHEMATIC ...

Page 43: ...Sections 9 0 Electrical Schematic Work Safely Always wear safety glasses near the machine ...

Page 44: ...SECTION 10 0 TROUBLESHOOTING ...