7

4.

Insert the hose and coupling into the die set as

illustrated. Position the coupling to the proper depth

according to the following guideline:

Coupling with crimp location markings: Several

Kurt Hydraulics couplings are manufactured with a

knurl mark on the circumference of the ferrule.

Looking down from the die set, line up the middle

of the knurl with the top edge of the die set.

Coupling without crimp location markings:

Refer to the Kurt Hydraulics crimp specification for die position.

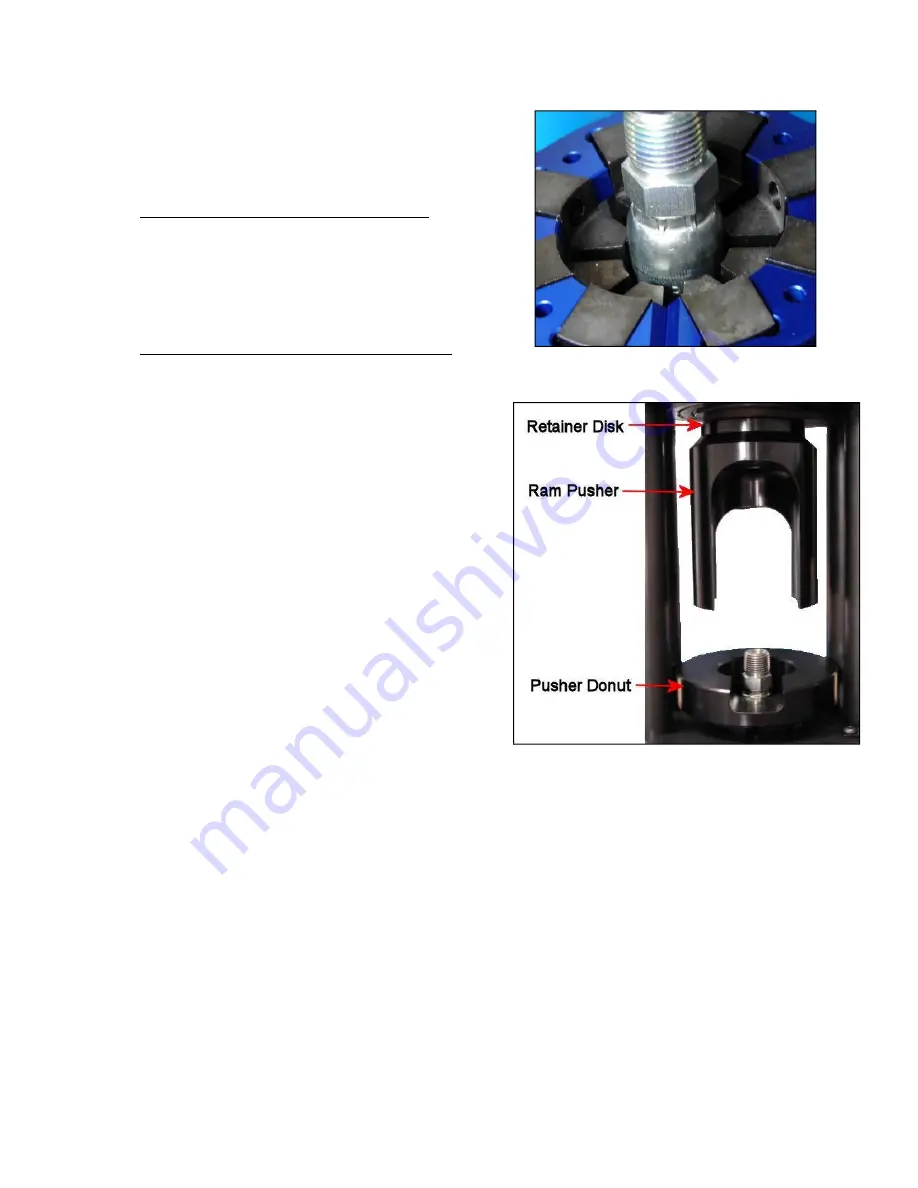

5.

Manually place the pusher donut on top of the die

set with the clearance slot facing forward to the

operator. Be sure the top rings of the die set are

evenly contained inside the bottom of the pusher

donut.

6.

Seat the die set in the cone base by firmly

pushing down on the pusher donut. Check the

alignment of the die set to make sure the die

holders are level and are not overlapping.

7.

Slide the ram pusher onto the retainer disk at the

end of the ram.

8.

Select the proper micrometer setting from the

Kurt Hydraulics crimp specification and twist the

top of the micrometer until that number appears on the micrometer barrel.

9.

Depress and hold the foot switch.

10.

Ram pusher will travel downward and engage pusher donut until the micrometer foot contacts

the limit switch.

11.

Release the foot switch once the micrometer contacted the limit switch and the pump has shut

off.